Lubricating agent for combined-cold-extrusion plastic forming of shaped charge liner and preparation method of lubricating agent

A technology of plastic forming and cold extrusion, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of armor penetration performance impact, surface roughness increase, drug-type cover quality is not high, to improve the surface quality and Yield rate, friction coefficient reduction, good oiliness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

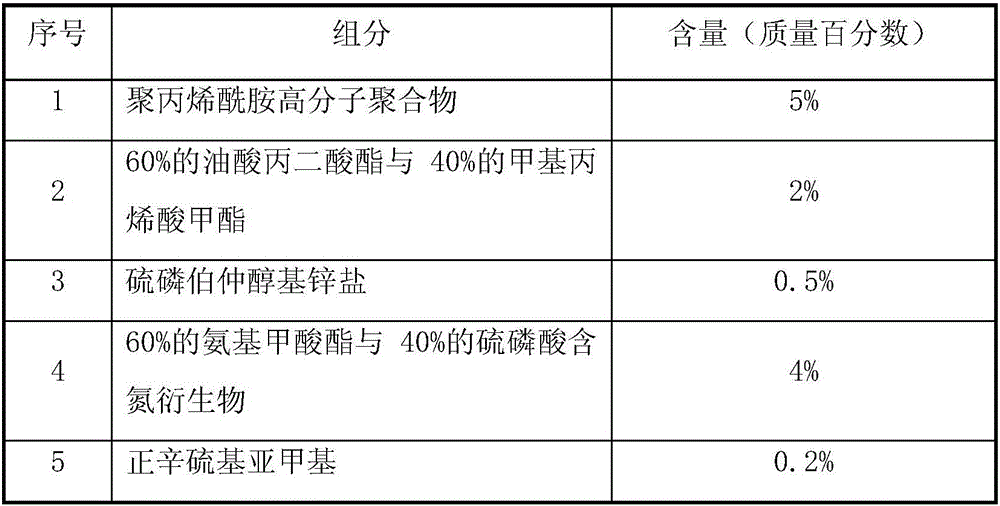

[0034] The components of the lubricant for composite cold extrusion plastic forming of the drug-type cap proposed in this embodiment are shown in the table.

[0035] Table 1: Lubricant composition list for compound cold extrusion plastic forming of drug-type cover

[0036]

[0037]

[0038] Prepare the drug-type cover compound cold extrusion plastic forming lubricant method of above-mentioned component as follows, and concrete content is weighed as shown in table 1:

[0039](1) Add the mixture of borax, oleic acid malonate and methyl methacrylate into a stirring container, heat up to 90°C, stir at a constant temperature for 60 minutes, wait for the temperature to drop to 45°C, continue stirring for 90 minutes, and wait for cooling to room temperature Add deionized water to get water-based lubrication;

[0040] (2) Add n-octylthiomethylene and butyl stearate in the stirring vessel, stir for 45min and set aside;

[0041] (3) Add primary and secondary sulfur phosphorus al...

Embodiment 2

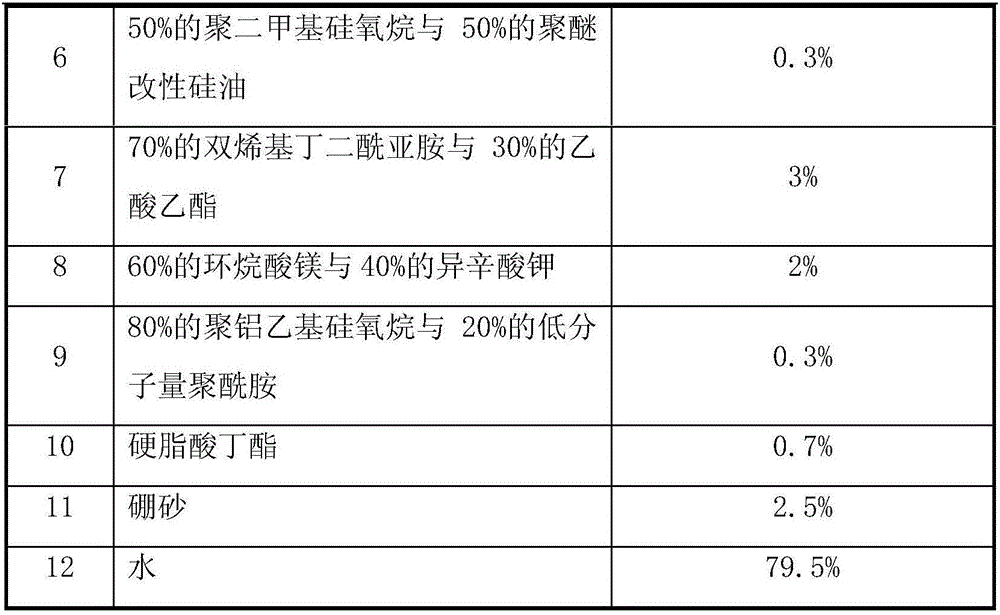

[0050] The components of the lubricant for composite cold extrusion plastic forming of the drug-type cap proposed in this embodiment are shown in the table.

[0051] Table 3: Lubricant composition list for compound cold extrusion plastic forming of liner

[0052]

[0053] The method for preparing the lubricant for the composite cold extrusion plastic forming of the above-mentioned components is as follows, and the specific content is weighed as shown in Table 3:

[0054] (1) Add the mixture of borax, oleic acid malonate and methyl methacrylate into a stirring container, heat up to 95°C, stir at a constant temperature for 50 minutes, wait for the temperature to drop to 40°C, continue stirring for 95 minutes, and wait for cooling to room temperature Add deionized water to get water-based lubrication;

[0055] (2) Add n-octylthiomethylene and butyl stearate in the stirring container, stir for 65min and set aside;

[0056] (3) Add primary and secondary sulfur phosphorus alcoh...

Embodiment 3

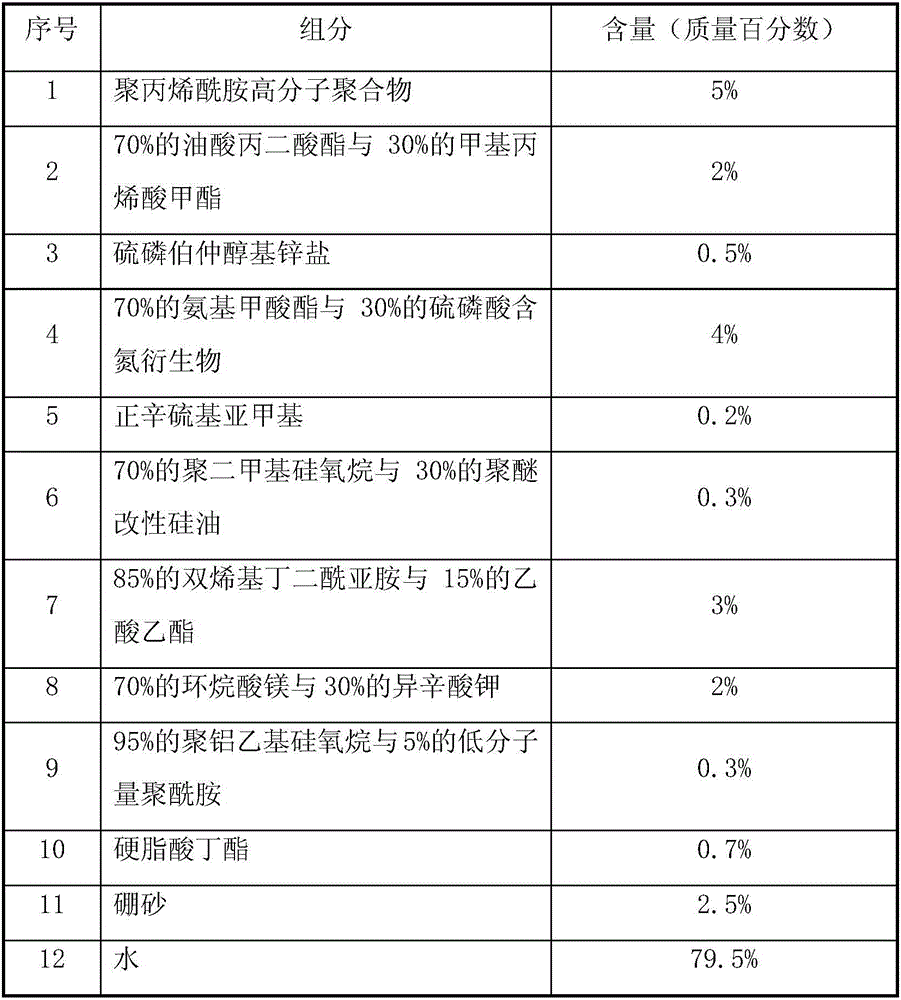

[0066] The components of the lubricant for composite cold extrusion plastic forming of the drug-type cap proposed in this embodiment are shown in the table.

[0067] Table 5: Lubricant composition list for compound cold extrusion plastic forming of drug-type cover

[0068]

[0069]

[0070] Prepare the medicine type cover compound cold extrusion plastic forming lubricant method of above-mentioned component as follows:

[0071] (1) Add the mixture of borax, oleic acid malonate and methyl methacrylate into a stirring container, heat up to 85°C, stir at a constant temperature for 50 minutes, wait for the temperature to drop to 35°C, continue stirring for 65 minutes, and wait for cooling to room temperature Add deionized water to get water-based lubrication;

[0072] (2) Add n-octylthiomethylene and butyl stearate in the stirring container, stir for 35min and set aside;

[0073] (3) Add primary and secondary sulfur phosphorus alcohol zinc salt, mixture of carbamate and sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com