Copper foil surface passivation liquid and treatment method thereof, and treated copper foil

A treatment method and a technology of passivation solution, which are applied in the coating process of metal materials, etc., can solve the problems of large demand and poor economic efficiency of the electroplating process, and achieve the effect of maintaining the same physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

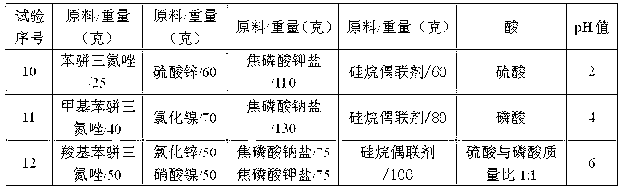

Embodiment 1

[0021] Weigh benzotriazole and / or benzotriazole derivatives, dissolve in 1 liter of deionized water, stir until the solution is clear, then add soluble inorganic salts, start the configuration circulation pump, stir the solution evenly, and control the solution temperature At 25°C, start the passivation solution configuration pump, spray the passivation solution onto the foil surface through the spray pipe, squeeze the foil surface with the squeeze roller, squeeze the passivation solution evenly, and control the spraying time for about 2 seconds . The passivated copper foil is post-baked in an oven at 110°C for 2 seconds to form a dense anti-oxidation protective film on the surface of the foil. Put the copper foil in an oven and bake it at 160°C for 10 minutes, and there will be no color difference on the surface of the copper foil; the oxidation resistance of this layer can reach 10 minutes at 160°C.

[0022]

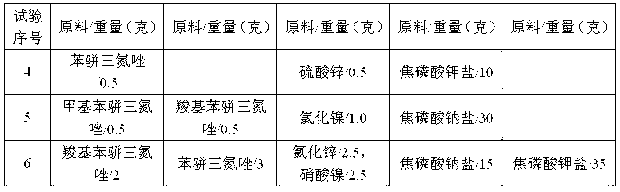

Embodiment 2

[0024] Weigh benzotriazole and / or benzotriazole derivatives, dissolve in 1 liter of deionized water, stir until the solution is clear, then add soluble inorganic salts and pyrophosphate, start the configuration circulation pump, and stir the solution evenly , the solution temperature is controlled at 45°C, start the passivation solution configuration pump, spray the passivation solution onto the foil surface through the spray pipe, squeeze the foil surface with the squeeze roller, squeeze the passivation solution evenly, and control the spraying time About 5 seconds. The passivated copper foil is post-baked in an oven at 160°C for 5 seconds to form a dense anti-oxidation protective film on the surface of the foil. . Put the copper foil in an oven and bake it at 160°C for 30 minutes or at 180°C for 10 minutes. There will be no color difference on the surface of the copper foil; minute.

[0025]

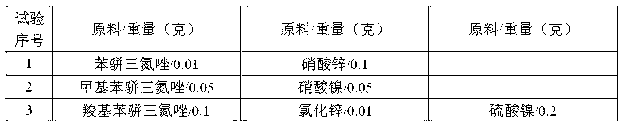

Embodiment 3

[0027] Weigh benzotriazole and / or benzotriazole derivatives, dissolve in 1 liter of deionized water, stir until the solution is clear, then add soluble inorganic salts, pyrophosphate and silane coupling agent, and start to configure the circulation pump , Stir the solution evenly, control the temperature of the solution at 40°C, start the passivation solution configuration pump, spray the passivation solution onto the foil surface through the spray pipe, squeeze the foil surface with the squeeze roller, squeeze the passivation solution Uniform, controlled spraying time is about 8 seconds. The passivated copper foil is post-baked in an oven at 170°C for 8 seconds to form a dense anti-oxidation protective film on the surface of the foil. . Put the copper foil in an oven and bake it at 213°C for 10 minutes. There will be no color difference on the surface of the copper foil, and the oxidation resistance of this layer can reach 10 minutes at 213°C.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com