Trivalent chromium plating solution composite, preparation method thereof and chromium plating process

A composition, technology of trivalent chromium, applied in the field of electroplating chromium, can solve the problems of natural degradation, expensive, difficult management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Preparation of additives and plating solution

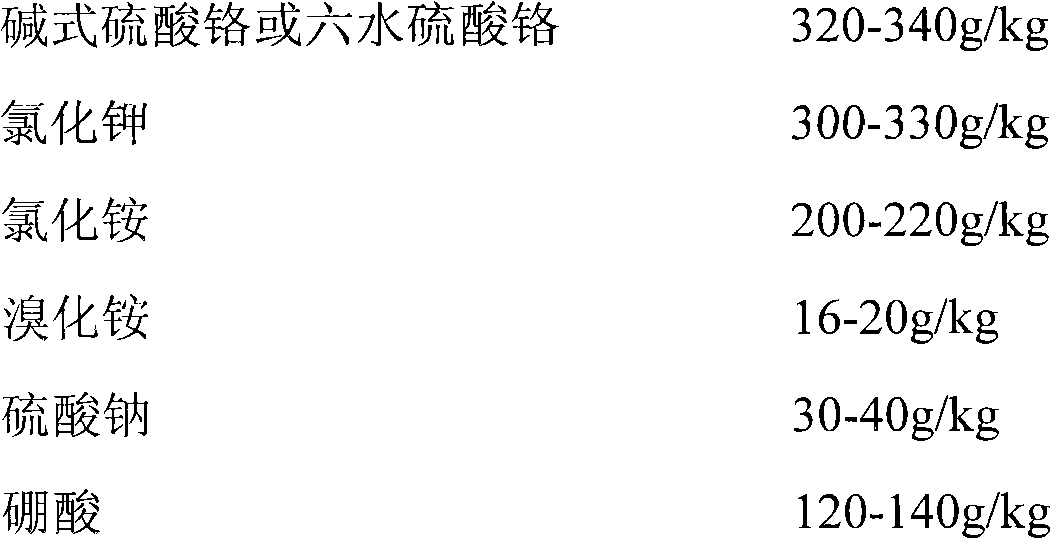

[0040] 1) Preparation of cylinder opener (calculated in 1kg):

[0041]

[0042] Accurately weigh the above raw materials and mix them evenly.

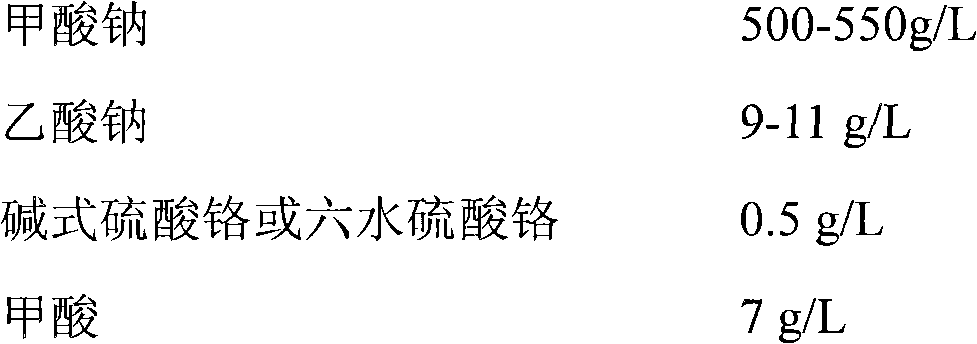

[0043] 2) Preparation of stabilizer (calculated by 1L):

[0044]

[0045] After accurately weighing the above raw materials, put them into a beaker, dissolve them all and stir evenly.

[0046] 3) Preparation of blending agent (1L):

[0047] Isooctanol 40g / L

[0048] Formaldehyde 1g / L

[0049] After accurately weighing the above raw materials, put them into a beaker, dissolve them all and stir evenly.

[0050] 4) Preparation of repairing agent (1L):

[0051] Ferrous ammonium sulfate 260g / L

[0052] Sulfuric acid 20g / L

[0053] Sodium formate 0.5g / L

[0054] After accurately weighing the above raw materials, put them into a beaker, dissolve them all and stir evenly.

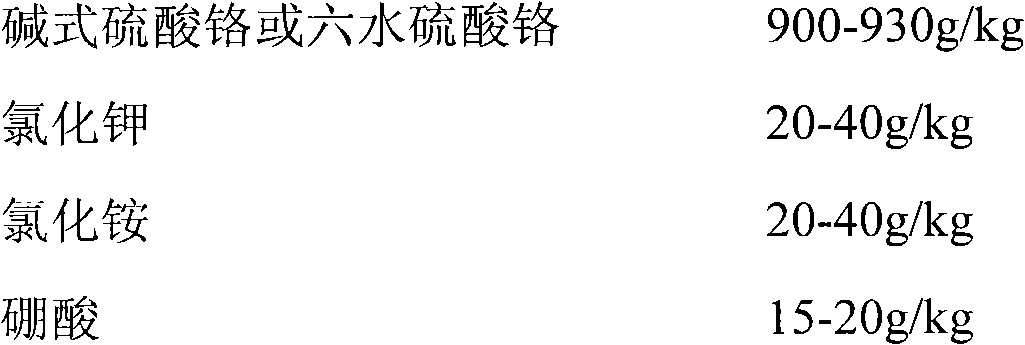

[0055] 5) Preparation of regulator (1Kg):

[0056]

[0057] Accurately weigh the above raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com