Method for processing chrome wastewater

A technology for chromium wastewater and wastewater, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc. The effect of dosage, low price and excellent trivalent chromium adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

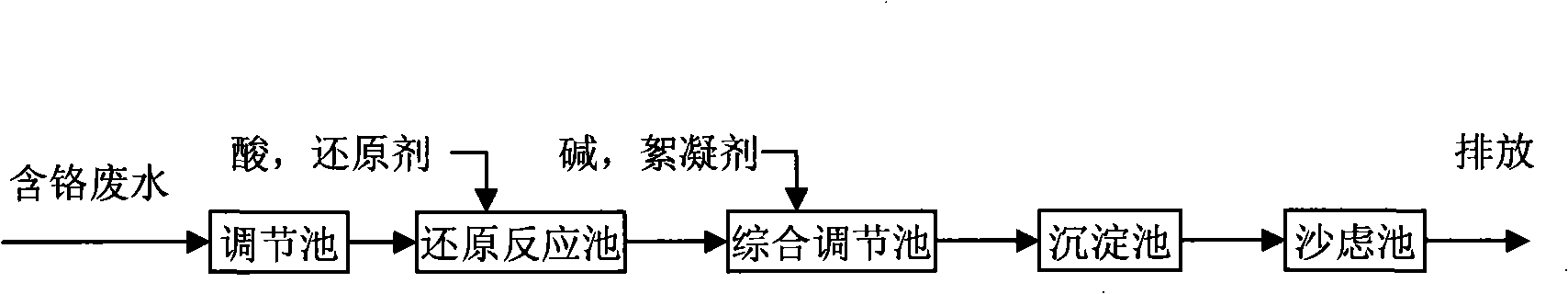

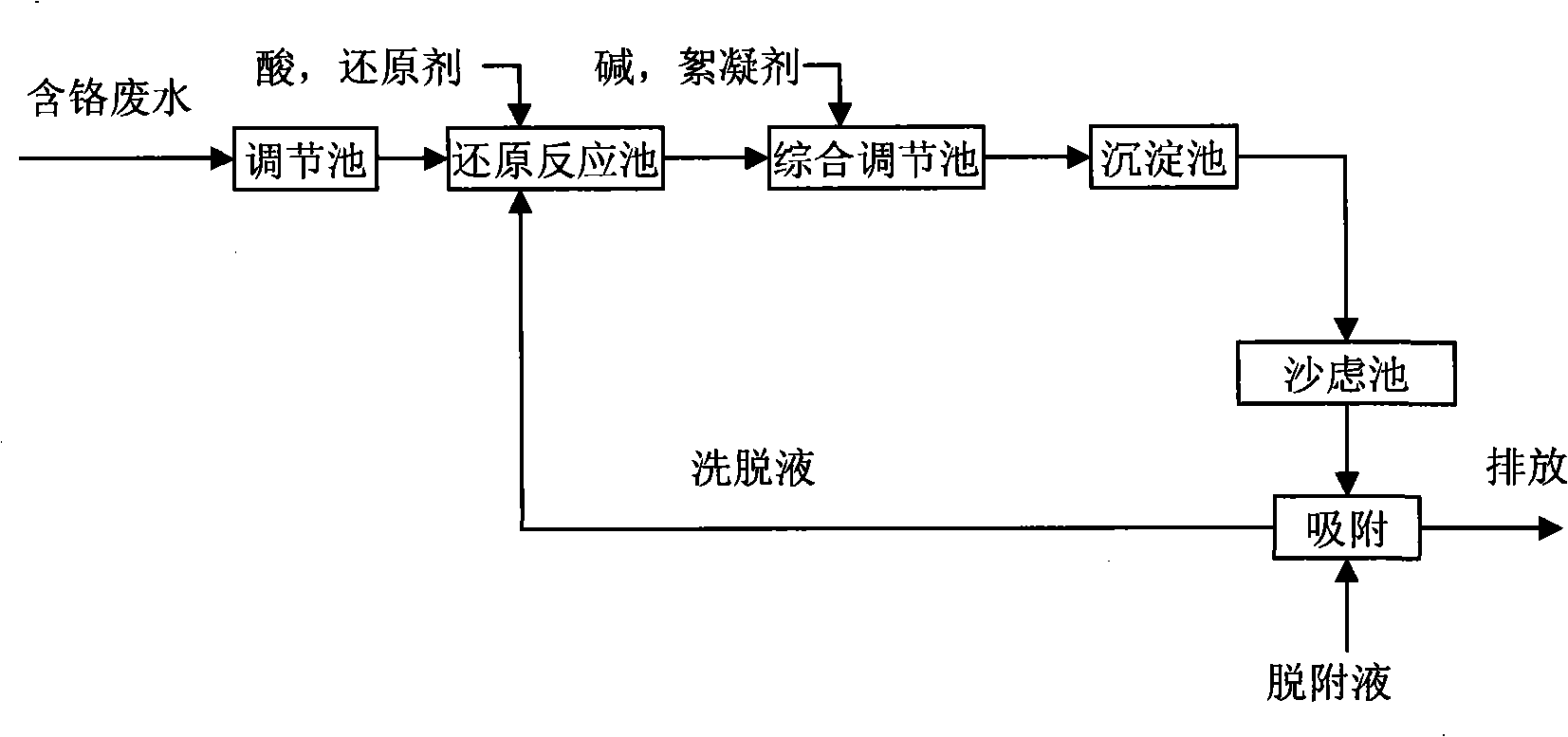

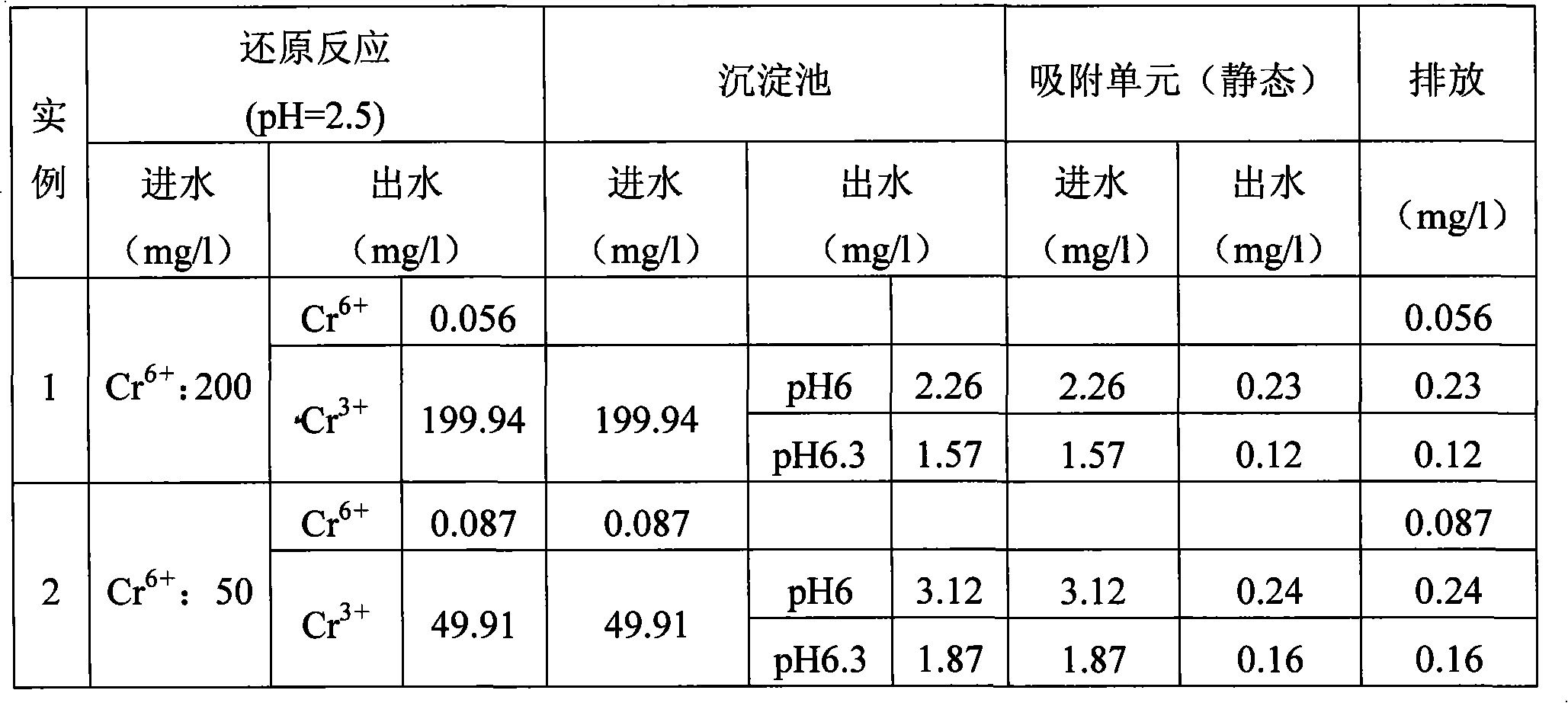

[0024] Such as figure 2 As shown, the wastewater enters the chromium-containing wastewater regulating tank to adjust the water quality and quantity, and then is sent to the reduction reaction tank, and the reducing agent NaHSO is added to the reduction reaction tank 3 , and use H 2 SO 4 Add an eluent to adjust the pH of the solution to between 2 and 3, so that the hexavalent chromium in the wastewater is reduced to trivalent chromium, and then the wastewater enters the comprehensive adjustment tank, and the pH of the wastewater is adjusted to 6 to 6.3 in the comprehensive adjustment tank, so that Formation of Cr(OH) from trivalent chromium ions in wastewater 3Precipitation, after adding the flocculant, the wastewater enters the sedimentation tank for solid-liquid separation, and the supernatant is filtered through the sand filter tank, and the filtered water also contains a small amount of trivalent chromium ions, the concentration of which is within the range of 3-4mg / l. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com