High-precision ultra-thin very-wide cold-rolled steel band, chrome-plated steel band for shield of optical fibre cable and technology thereof

A cold-rolled steel strip, high-precision technology, applied in metal rolling and other directions, can solve the problems that chrome-plated steel strip cannot be shielded by optical fiber cables, high production cost of cold-rolled steel strip, poor shape of steel strip, etc., and achieve excellent mechanical properties , smooth surface and good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

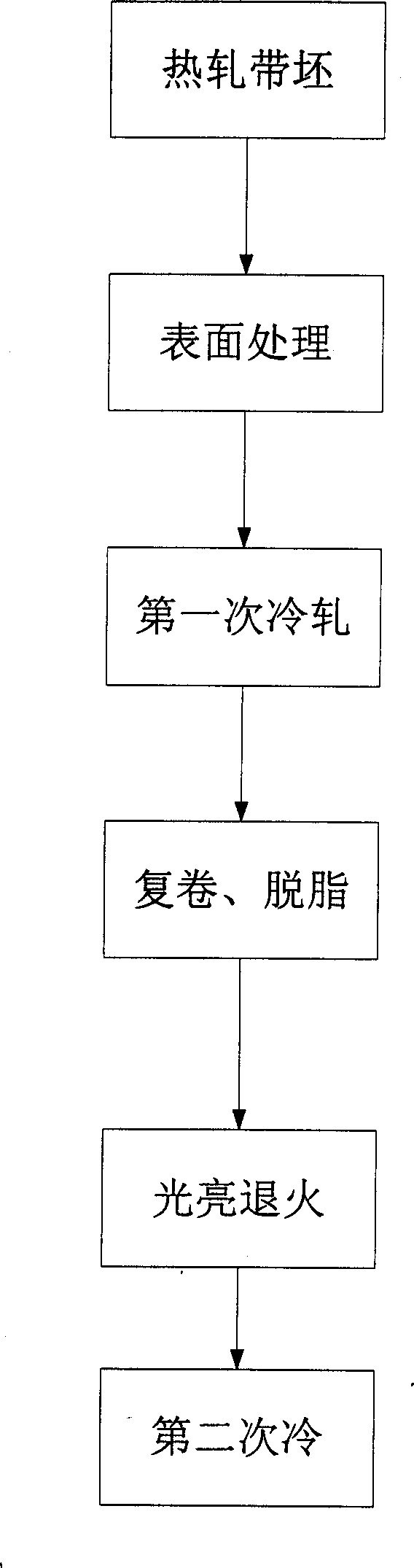

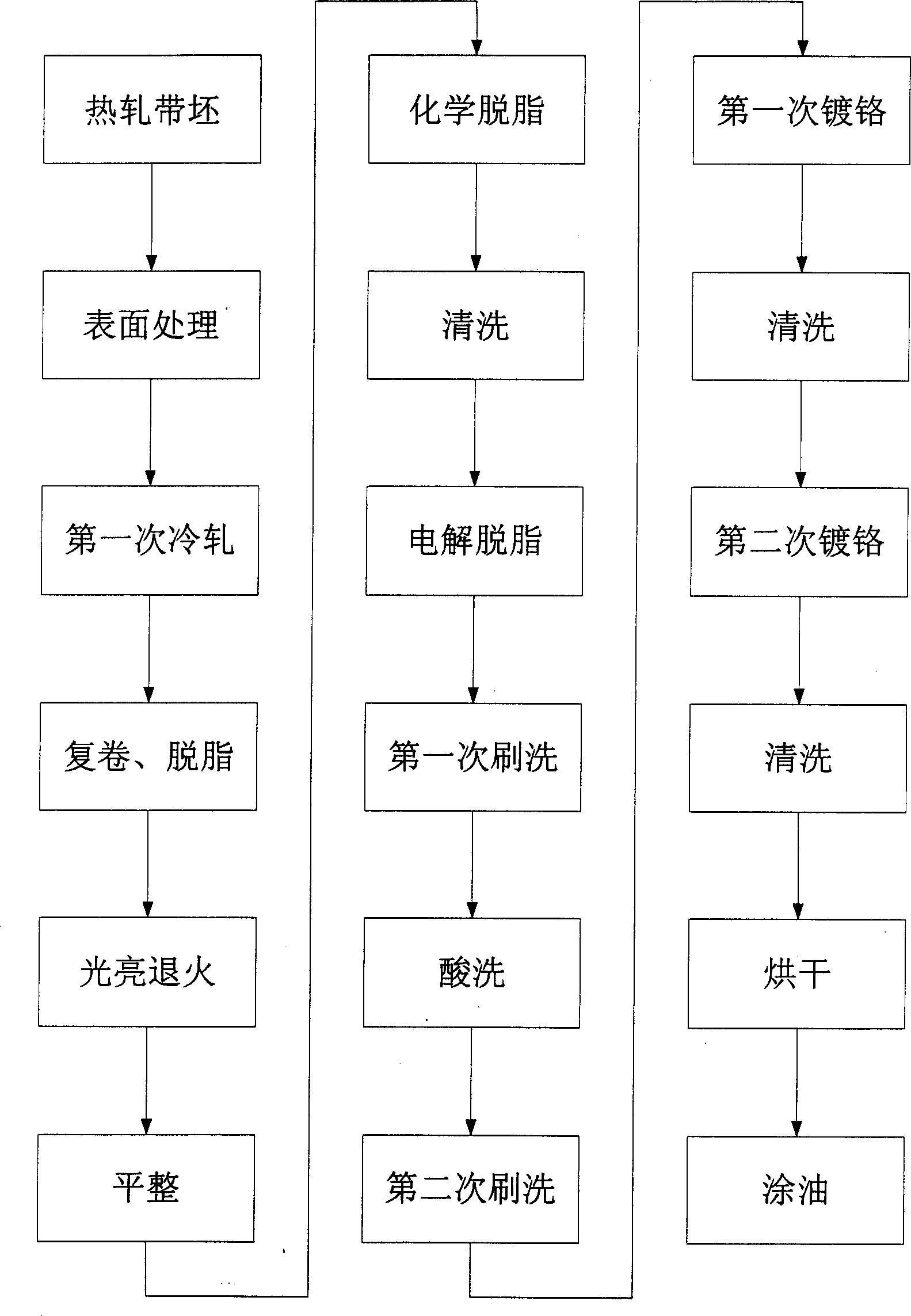

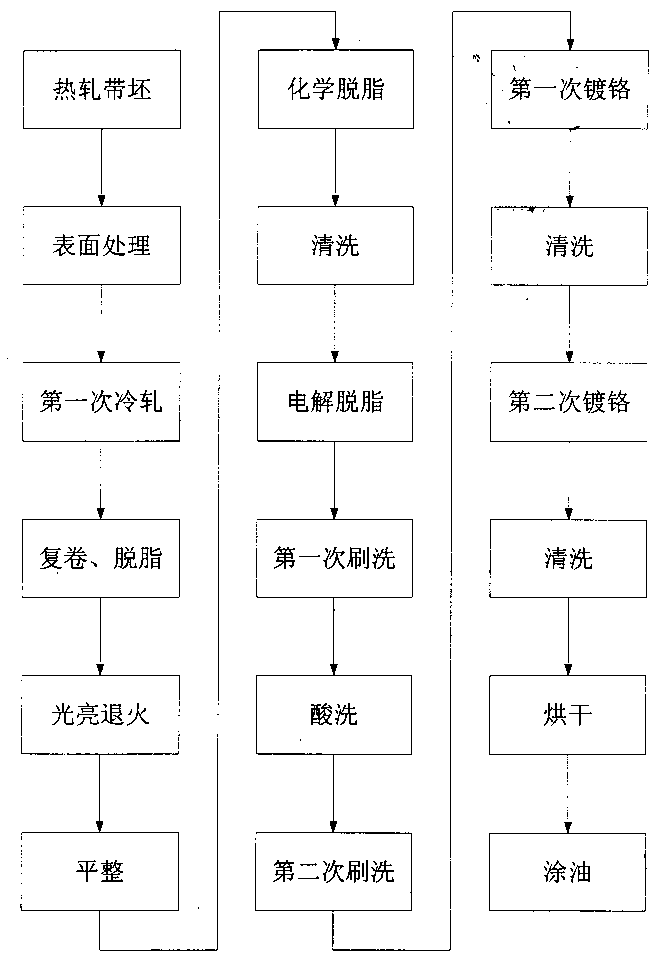

[0017] Such as figure 1 As shown, the processing process of the high-precision ultra-thin and extra-wide cold-rolled steel strip in the present invention is as follows: at first getting the hot-rolled strip blank with a thickness of 3 millimeters and a width of 600 millimeters, place the hot-rolled strip blank in 10% hydrochloric acid solution Medium immersion treatment, using hydrochloric acid to remove oxides on the surface of the hot-rolled strip; then the hot-rolled strip treated with hydrochloric acid is passed through a large-diameter four-roll reversing cold rolling mill with high steel strength, large rolling force, and high tension , using the four-roll reversing cold rolling mill to carry out multi-pass rolling of the hot-rolled strip, combining large reduction and small reduction, to obtain high-precision cold rolling with a thickness of 0.25 mm and a width of 600 mm. Rolled steel strip; then the high-precision cold-rolled steel strip is rewinded and degreased, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com