A method for extracting and rectifying separation of toluene and n-butanol mixture

An extractive distillation and extractive distillation column technology, which is applied in the separation and purification field of the chemical industry, can solve the problems of high energy consumption, complex operation process and large reflux in the rectification process, and achieves strong operability, simple process, solvent The effect of ratio and reflux ratio is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

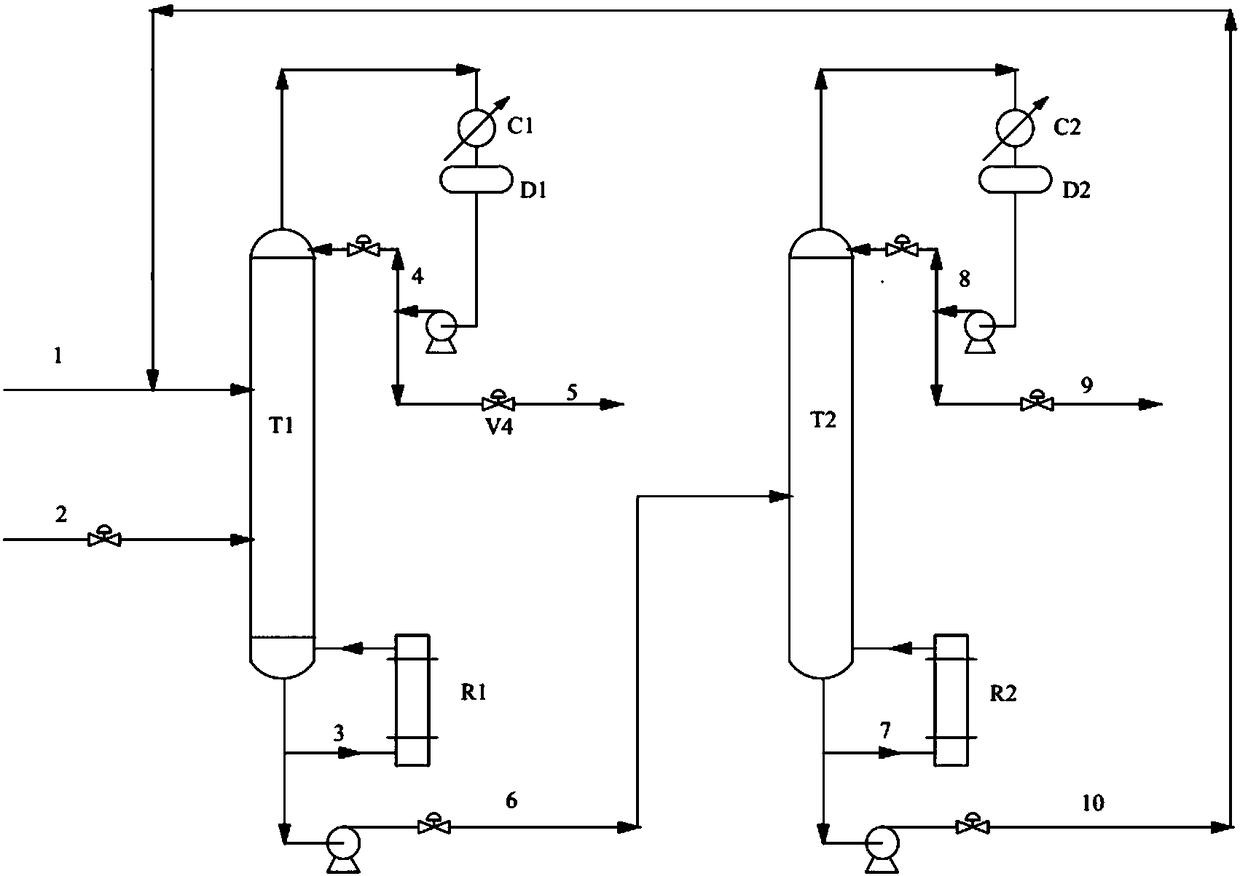

[0057] The feed temperature is 25° C., the flow rate is 500 kg / h, the pressure is 1 atm, and the feed contains 40% toluene and 60% n-butanol. The number of theoretical plates of the extractive distillation column is 36, the inner diameter of the column is 0.31m, the number of feeding plates of the mixture of toluene and n-butanol is 25, and the flow rate of the extractant dimethyl sulfoxide is 1000kg / h (the solvent ratio is 2:1), The number of feeding plates for the extractant is 15; the number of theoretical plates for the extraction agent recovery tower is 40, the inner diameter of the tower is 0.32m, and the number of feeding plates is 20. The operating pressure of the extractive distillation tower is 1 atm, the reflux ratio is 0.85, the temperature at the top of the tower is 110.7°C, and the temperature at the bottom of the tower is 160.5°C; The bottom temperature is 190.7°C. The purity of toluene after separation is 99.9%, the recovery rate of toluene is 99.9%, the purit...

Embodiment 2

[0059] The feed temperature is 25° C., the flow rate is 500 kg / h, the pressure is 1 atm, and the feed contains 60% toluene and 40% n-butanol. The number of theoretical plates of the extractive distillation column is 38, the inner diameter of the column is 0.34m, the number of feeding plates of the mixture of toluene and n-butanol is 28, and the flow rate of the extractant dimethyl sulfoxide is 1000kg / h (the solvent ratio is 2:1), The number of feeding plates for the extractant is 18; the number of theoretical plates for the extraction agent recovery tower is 42, the inner diameter of the tower is 0.35m, and the number of feeding plates is 20. The operating pressure of the extractive distillation tower is 1 atm, the reflux ratio is 0.9, the temperature at the top of the tower is 111°C, and the temperature at the bottom of the tower is 162.2°C; The bottom temperature is 191.3°C. The purity of toluene after separation is 99.9%, the recovery rate of toluene is 99.9%, the purity o...

Embodiment 3

[0061] The feed temperature is 25° C., the flow rate is 500 kg / h, the pressure is 1 atm, and the feed contains 80% toluene and 20% n-butanol. The theoretical plate number of the extractive distillation column is 40, the inner diameter of the column is 0.38m, the number of feeding plates for the mixture of toluene and n-butanol is 30, and the flow rate of the extractant dimethyl sulfoxide is 1000kg / h (the solvent ratio is 2:1), The number of feeding plates for the extractant is 20; the number of theoretical plates for the extraction agent recovery tower is 45, the inner diameter of the tower is 0.39m, and the number of feeding plates is 22. The operating pressure of the extractive distillation tower is 1 atm, the reflux ratio is 0.94, the temperature at the top of the tower is 119.5°C, and the temperature at the bottom of the tower is 164.1°C; The bottom temperature is 192.2°C. The purity of toluene after separation is 99.9%, the recovery rate of toluene is 99.9%, the purity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com