Epoxypropane purifying method

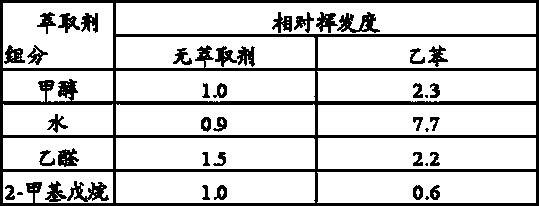

A technology of propylene oxide and purification method, which is applied in the direction of organic chemistry, can solve the problems of poor product quality and high cost of extraction agent, and achieve the effect of reducing cycle accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

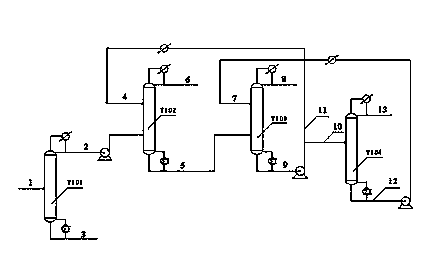

[0037] use figure 1 Process shown, containing water, acetaldehyde, propionaldehyde, methanol, acetone, C 5 ~C 7 The composition of stream 1 (crude propylene oxide solution) of impurities such as hydrocarbons is shown in Table 4.

[0038] Table 4

[0039] composition Content, wt acetone 0.008 Propionaldehyde 0.002 Acetaldehyde 0.001 Propylene oxide 0.987 water 0.001 C 5 ~C 7 Hydrocarbons 0.001

[0040] Stream 1 is fed from the lower part of T101 tower with a flow rate of 10000kg / h. Stream 3 (T101 tower bottom liquid) mainly contains water, propionaldehyde, acetone, C 7 Hydrocarbons, to the outside of the system, stream 2 (T101 overhead distillate) is pumped to 400 kPa and fed from the lower part of T102 tower. The theoretical plate number of T101 column is 50, the feed plate position is the 32nd plate, the operating pressure is controlled at 150kPa, and the reflux ratio is 2.6.

[0041] Stream 4 (T103 kettle liquid) is...

Embodiment 2

[0050] use figure 1 Process shown, containing water, acetaldehyde, propionaldehyde, methanol, acetone, C 5 ~C 7 The composition of stream 1 (crude propylene oxide solution) of impurities such as hydrocarbons is shown in Table 6.

[0051] Table 6

[0052] composition Content, wt acetone 0.008 Propionaldehyde 0.002 Acetaldehyde 0.001 Propylene oxide 0.987 water 0.001 C 5 ~C 7 Hydrocarbons 0.001

[0053] Stream 1 is fed from the lower part of T101 tower with a flow rate of 10000kg / h. Stream 3 (T101 tower bottom liquid) mainly contains water, propionaldehyde, acetone, C 7 Hydrocarbons, to the outside of the system, stream 2 (T101 overhead distillate) is pumped to 400 kPa and fed from the lower part of T102 tower. The theoretical plate number of T101 column is 55, the feed plate position is the 34th plate, the operating pressure is controlled at 160kPa, and the reflux ratio is 2.5.

[0054] Stream 4 (T103 kettle liquid) is...

Embodiment 3

[0063] use figure 1 Process shown, containing water, acetaldehyde, propionaldehyde, methanol, acetone, C 5 ~C 7 The composition of stream 1 (crude propylene oxide solution) of impurities such as hydrocarbons is shown in Table 8.

[0064] Table 8

[0065] composition Content, wt acetone 0.009 Propionaldehyde 0.003 Acetaldehyde 0.002 Propylene oxide 0.982 water 0.002 C 5 ~C 7 Hydrocarbons 0.002

[0066] Stream 1 is fed from the lower part of T101 tower with a flow rate of 10000kg / h. Stream 3 (T101 tower bottom liquid) mainly contains water, propionaldehyde, acetone, C 7 Hydrocarbons, to the outside of the system, stream 2 (T101 overhead distillate) is pumped to 400 kPa and fed from the lower part of T102 tower. The theoretical plate number of T101 column is 58, the feeding plate position is the 35th plate, the operating pressure is controlled at 160kPa, and the reflux ratio is 2.4.

[0067] Stream 4 (T103 kettle liquid)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com