Separation method of propylene oxidation products epoxypropane, acrolein and acetone

A technology for the oxidation of propylene oxide and propylene, which is applied in the separation of acrolein and acetone, and in the field of propylene oxidation product propylene oxide, which can solve the problems of low relative volatility, large theoretical plate number and reflux ratio, and difficulty in applying chromatographic methods to industrial scale, etc. problems, to achieve the effect of high recovery rate and great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

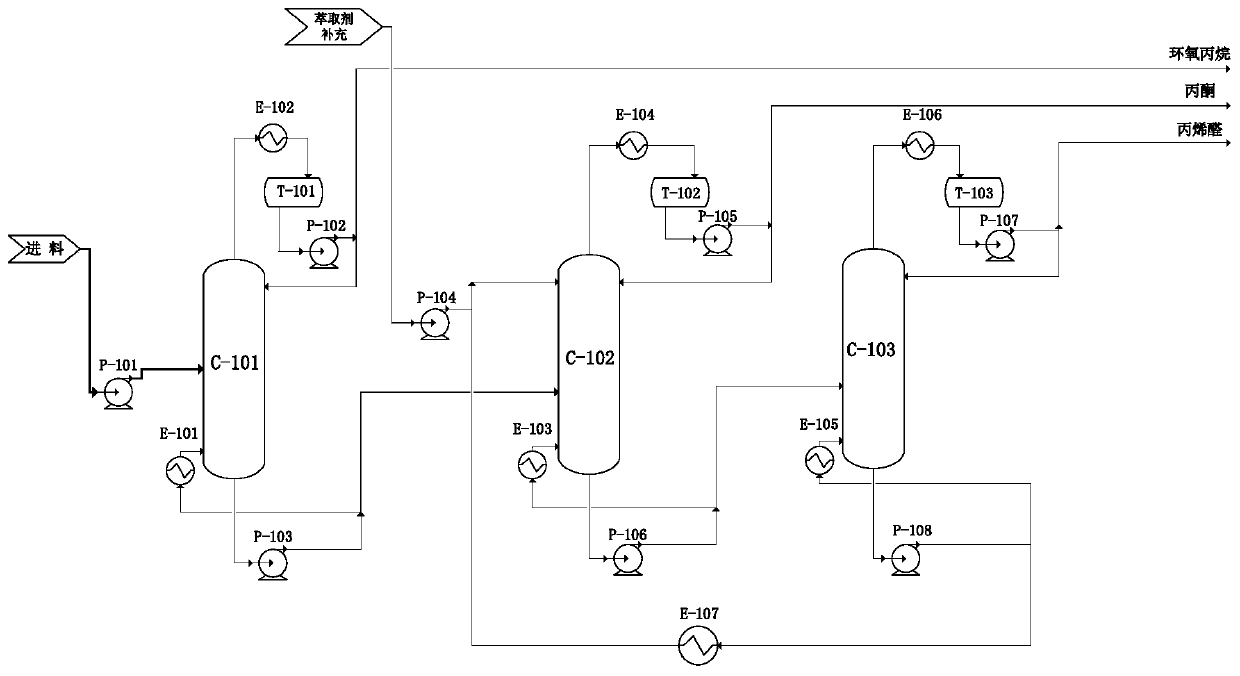

[0026] The material to be separated is a mixture of propylene oxide, acrolein and acetone with a mass ratio of 5:1:0.9. The material enters the propylene oxide tower C-101 from the 30th theoretical plate. The tower has 45 theoretical plates in total. The operating pressure at the top of the tower is 0.2MPa, the reflux ratio is 3.5, the temperature at the top of the tower is 54.9°C, and the temperature at the bottom of the tower is 76.3°C. The propylene oxide with a purity of 99.8% is obtained at the top of the tower, and the product recovery rate reaches 98.9%.

[0027] The materials in the propylene oxide tower and tower are mainly acrolein and acetone, and ethylene glycol is used as the extraction agent. The two enter the extractive distillation tower in two ways, and adopt atmospheric distillation. The material to be separated is fed from the 20th theoretical plate, the extractant is added from the 5th plate, and the feed flow ratio of the extractant to the raw material is ...

Embodiment 2

[0030] The same system to be separated as in Example 1 was selected, and the material to be separated was a mixture of propylene oxide, acrolein, and acetone, with a mass ratio of 5:1:0.9. The material enters the propylene oxide tower C-101 from the 25th theoretical plate. The tower has 40 theoretical plates in total. The operating pressure at the top of the tower is normal pressure, the reflux ratio is 2.71, the temperature at the top of the tower is 34.2°C, and the temperature at the bottom of the tower is 54.4°C. The propylene oxide product with a purity of 99.9% is obtained at the top of the tower, and the product recovery rate reaches 98.5%.

[0031] The materials in the propylene oxide tower and tower are mainly acrolein and acetone, and N,N-dimethyldiamide (DMF) is used as the extractant, and the two enter the extractive distillation tower in two ways, and adopt atmospheric distillation. Wherein, the extractive distillation column C-102 has 50 theoretical plates, and th...

Embodiment 3

[0034] Select the same system to be separated as in Example 1, and the material to be separated is a mixture of propylene oxide, acrolein, and acetone, with a mass ratio of 5:1:0.9. The material enters the propylene oxide tower C-101 from the 25th theoretical plate. The tower has 40 theoretical plates in total. The operating pressure at the top of the tower is normal pressure, the reflux ratio is 2.85, the temperature at the top of the tower is 34.2°C, and the temperature at the bottom of the tower is 54.4°C. The propylene oxide with a purity of 99.9% is obtained at the top of the tower, and the product recovery rate reaches 98.5%.

[0035] The materials in the propylene oxide tower and tower tank are mainly acrolein and acetone, and ethylene glycol is used as the extraction agent. The two enter the extractive distillation tower in two ways, and adopt atmospheric distillation. Wherein, the extractive distillation column C-102 has 37 theoretical plates, and the material to be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com