Method for producing glufosinate-ammonium with low energy consumption

A glufosinate-ammonium, low-energy-consumption technology, applied in the field of low-energy-consumption production of glufosinate-ammonium, can solve the problems of high operating costs and high energy consumption, and achieve the effects of reduced energy consumption, low energy consumption, and easy collection and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

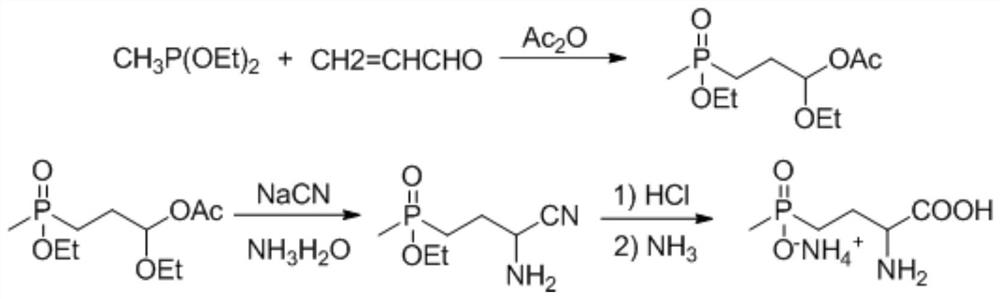

Image

Examples

Embodiment 1

[0033] In the experiment, a DN32, 800mm long Hastelloy tube and electric heating were used as the cracking reaction device. The feed rate of methane was 1 cubic / h, and the feed rate of phosphorus trichloride (containing 4.5% carbon tetrachloride) was 1.2kg. / h, the reaction temperature is 600°C, and the pyrolysis product is obtained. The feed rate of xylene at -10°C in the product capture system is 1kg / h, and the high-temperature gas is downstream, and the pyrolysis product is collected at 2.15kg / h, and the components are analyzed and detected. Content: 8.1% methylphosphine dichloride, 44.5% phosphorus trichloride, 46.5% p-xylene, 0.5% carbon tetrachloride;

[0034]The experiment adopts a set of Φ30mm glass rectification tower with θ ring packing inside. The height of the tower is 3 meters (the number of theoretical plates is 70-75). The ratio is 1:1, the temperature at the bottom of the tower is 110°C, the temperature at the top of the tower is 74°C, phosphorus trichloride wi...

Embodiment 2

[0039] Same as Example 1, the trapping agent is adjusted to toluene, and the content of each component of the detected cracking product is: 8.2% methylphosphine dichloride, 44.7% phosphorus trichloride, 46.5% toluene, 0.5% carbon tetrachloride;

[0040] Phosphorus trichloride rectification separation process reflux ratio is replaced by 2:1, the tower top temperature is 74 ℃, the resulting phosphorus trichloride purity is 98%, the methyl phosphine dichloride containing a small amount of phosphorus trichloride and The content of each component of the mixture of toluene is: 14.7% methyl phosphine dichloride, 1.5% phosphorus trichloride, 83.5% toluene;

[0041] The content of triethyl phosphite obtained by rectification after reaction with ethanol is 98%, and the content of toluene recovered by vacuum distillation after acetal reaction is 99.2%;

[0042] It is prior art to obtain glufosinate-ammonium through cyanamide and hydrolysis reaction of acetal, and the method disclosed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com