Method for producing high-purity cyclopentadiene and cyclopentane by coarse piperyene

A technology of crude piperylene and cyclopentane, applied in organic chemistry, isomerization hydrocarbon production, etc., can solve the problems that the separation of cyclopentene and piperylene cannot be realized, and achieve easy industrial production and high product quality The effect of stability and high purification precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

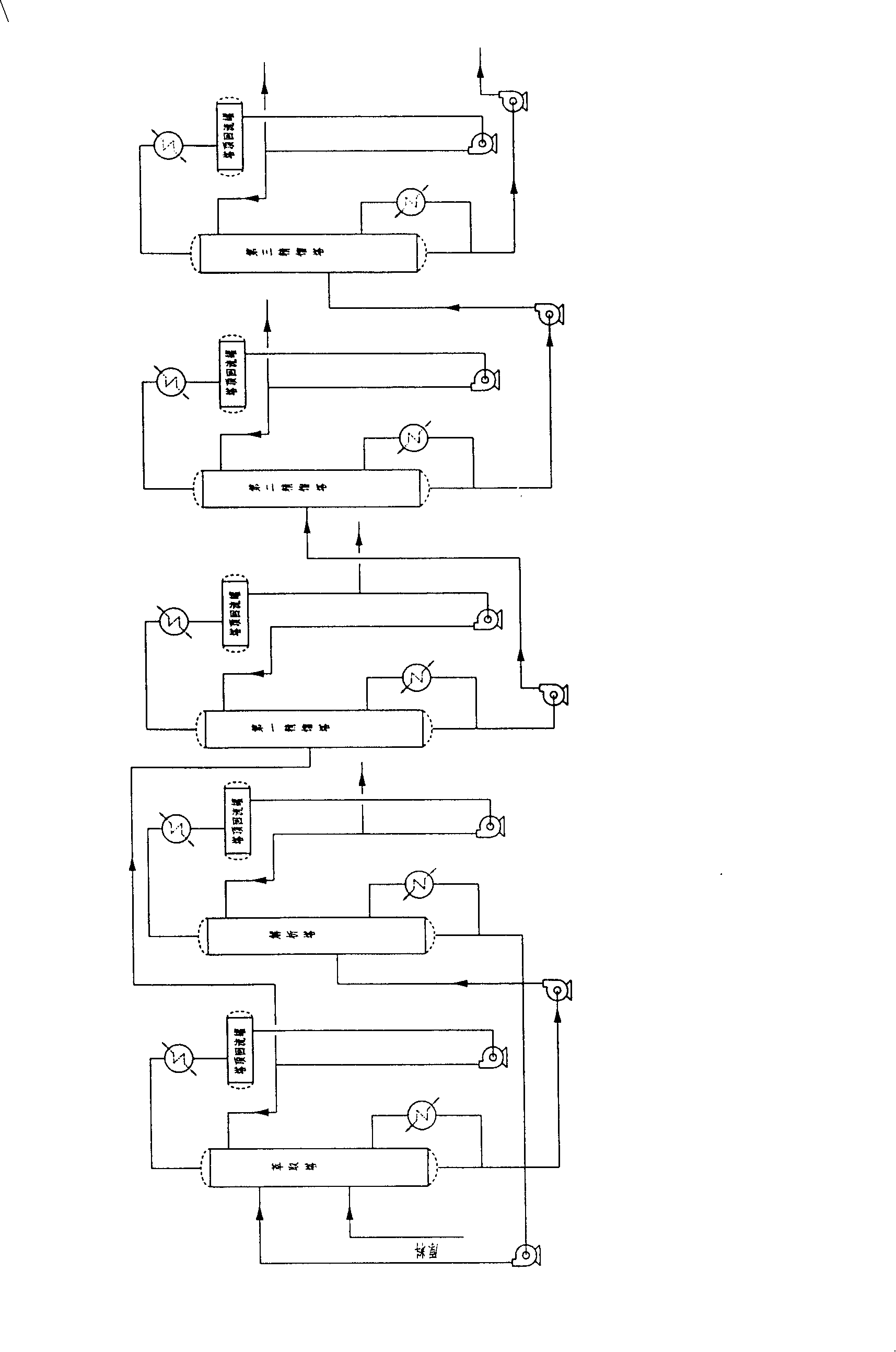

Image

Examples

Embodiment 1

[0029] The crude piperylene raw material enters the extraction tower in the presence of the polymerization inhibitor SP-731, and contacts with the extraction agent dimethylformamide added at the top of the tower. The operating pressure of the extraction tower is controlled to be: 0.14, the temperature is 52°C, and the reflux ratio is 2, The volume ratio of dimethylformamide to raw material is 4:1, the feed temperature is 70°C, and cyclopentene and cyclopentane mixture are obtained from the top of the tower, and the bottom of the tower is the extractant and piperylene. The extraction agent and piperylene from the tower bottom enter the desorption tower, the operating pressure is normal pressure, the temperature of the tower bottom is 160°C, the tower bottom liquid is returned to the extraction tower or the solvent removal recovery system, and high-purity refined piperylene is distilled from the top of the tower. Put the top material into the first rectification tower, the operat...

Embodiment 2

[0031] The crude piperylene raw material enters the extraction tower in the presence of the polymerization inhibitor SP-731, contacts with the extraction agent dimethylformamide added at the top of the tower, and controls the operating pressure of the extraction tower: 0.17Mpa, temperature 135°C, reflux ratio 9. The volume ratio of dimethylformamide to raw material is 10:1, the feed temperature is 95°C, and the mixture of cyclopentene and cyclopentane is obtained from the top of the tower, and the bottom of the tower is the extractant and piperylene. The extraction agent and piperylene from the tower bottom enter the desorption tower, the operating pressure is normal pressure, the temperature of the tower bottom is 100°C, the tower bottom liquid is returned to the extraction tower or the solvent removal recovery system, and high-purity refined piperylene is distilled from the top of the tower. Put the top material into the first rectification tower, the operating pressure is 0....

Embodiment 3

[0033] The crude piperylene raw material enters the extraction tower in the presence of the polymerization inhibitor SP-731, and contacts with the extraction agent dimethylformamide added at the top of the tower. The operating pressure of the extraction tower is controlled to be: 0.16Mpa, the temperature is 85°C, and the reflux ratio is 6 , the volume ratio of dimethylformamide to raw material is 7:1, the feed temperature is 80°C, cyclopentene and cyclopentane mixture are obtained from the top of the tower, and the bottom of the tower is the extractant and piperylene. The extraction agent and piperylene from the tower bottom enter the desorption tower, the operating pressure is normal pressure, the temperature of the tower bottom is 80°C, the tower bottom liquid is returned to the extraction tower or the solvent removal recovery system, and high-purity refined piperylene is distilled from the top of the tower. Put the top material into the first rectification tower, the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com