Patents

Literature

41results about How to "High purification precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wide-temperature high-efficiency catalyst for NOx removal by ammonia selective catalytic reduction ]and preparation method thereof

ActiveCN103877988AGood air source adaptabilityLow temperature resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthManganese oxide

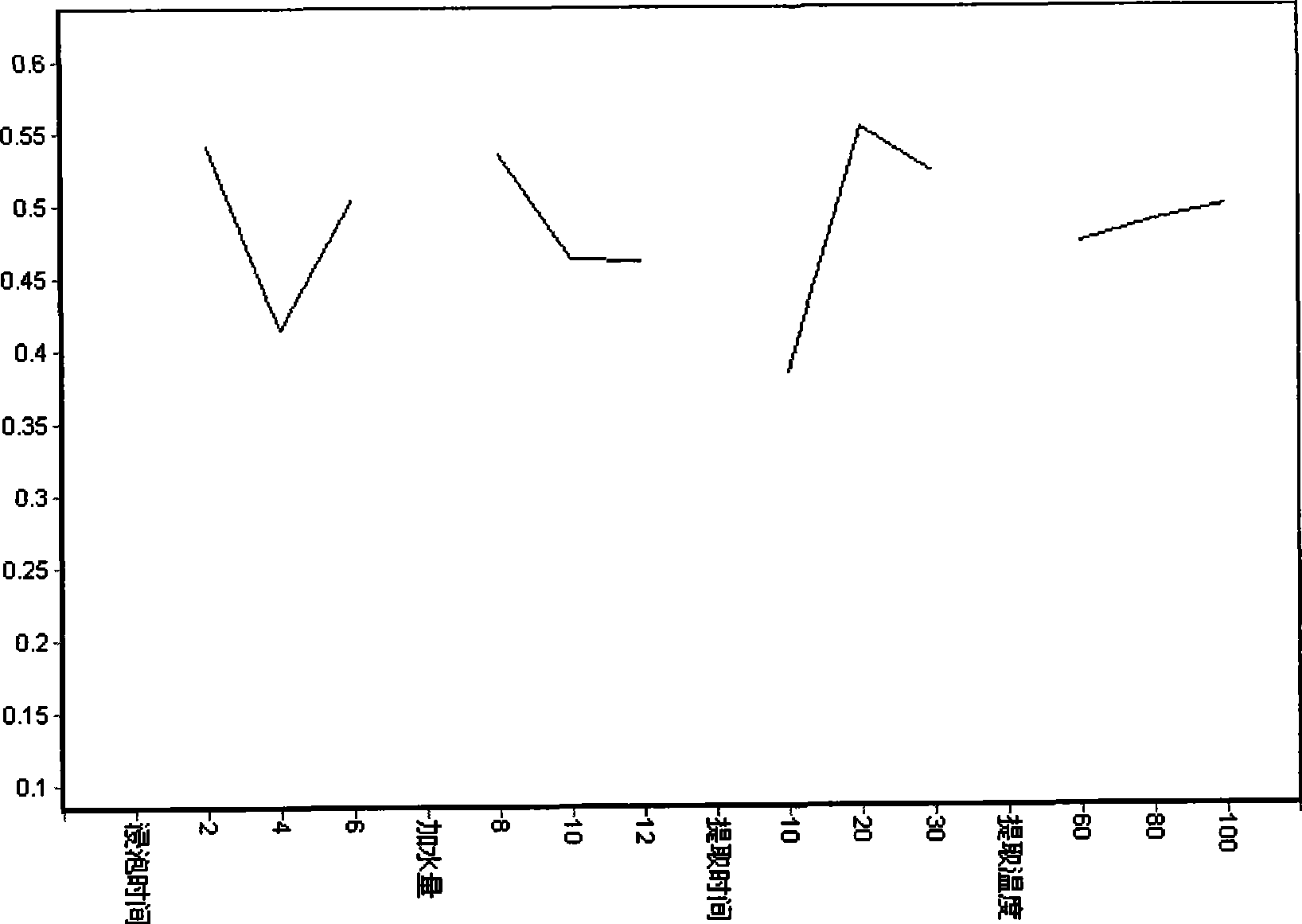

The invention belongs to the technical field of catalysts and especially provides a wide-temperature high-efficiency NOx removal catalyst for ammonia selective catalytic reduction and a preparation method thereof. The catalyst consists of an active component, an auxiliary agent and a carrier. The weight of the active component accounts for 2%-10% of the weight of the catalyst, and the weight of the auxiliary agent accounts for 0.5%-7% of the weight of the catalyst. The active component is composed of a cupric oxide and / or a manganese oxide; the auxiliary agent is a mischmetal, a rare earth oxide or a transition metal oxide; and the carrier is Al2O3 or TiO2-Al2O3. The catalyst is particularly prepared by the steps of a drying operation and a roasting operation at a proper temperature. An NOx removal process at a wide temperature zone ranging from 100 DEG C to 400 DEG C can be achieved by the catalyst of the invention; meanwhile, the catalyst can be repeatedly used in normal after being washed and regenerated for several times in a nitrate tail gas denitration technology, and the catalytic intensity and the denitration performance are not decreased obviously. The catalyst of the invention is industrialized and has excellent industrial application prospect.

Owner:DALIAN CATALYTIC ENG TECH

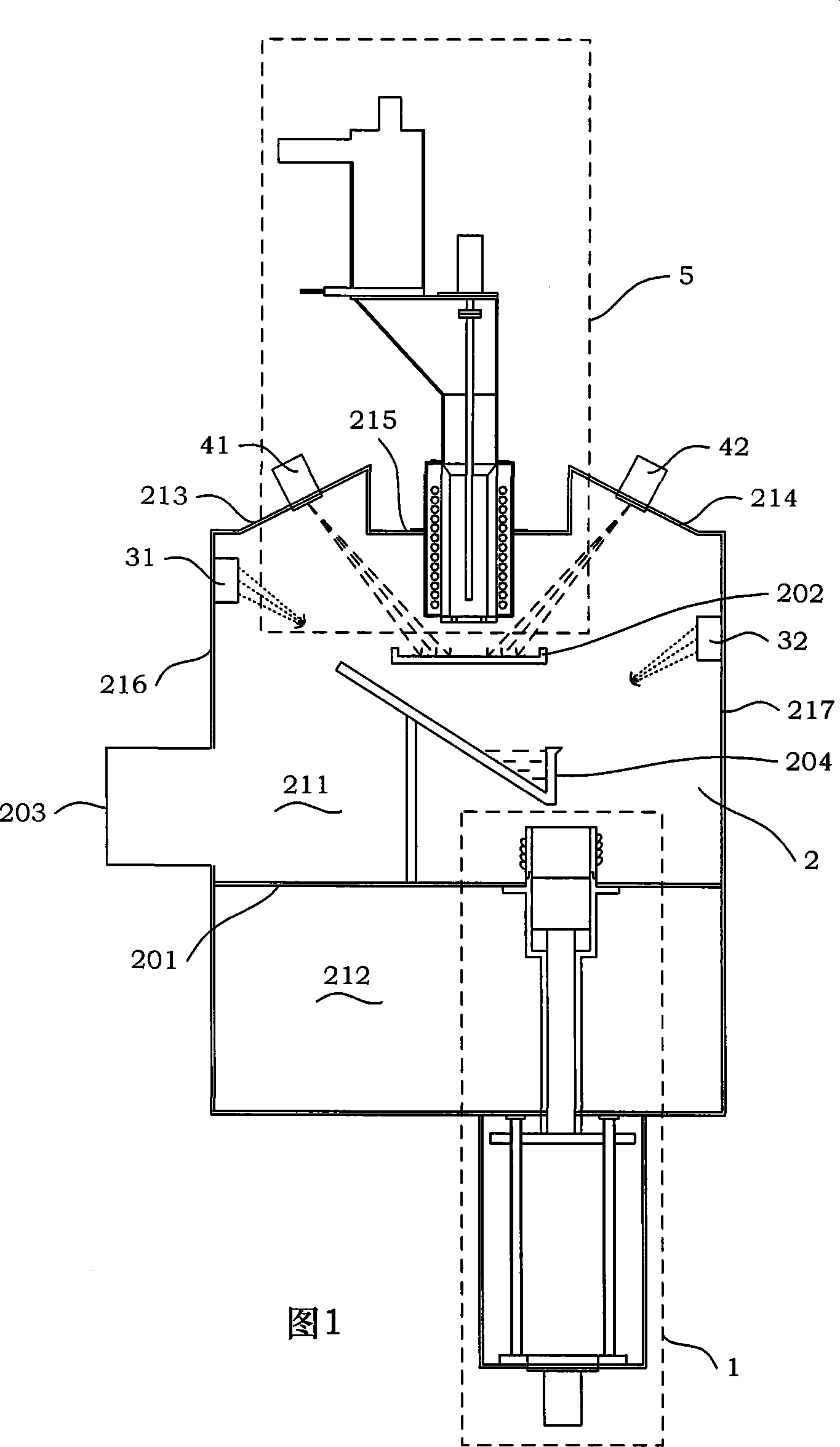

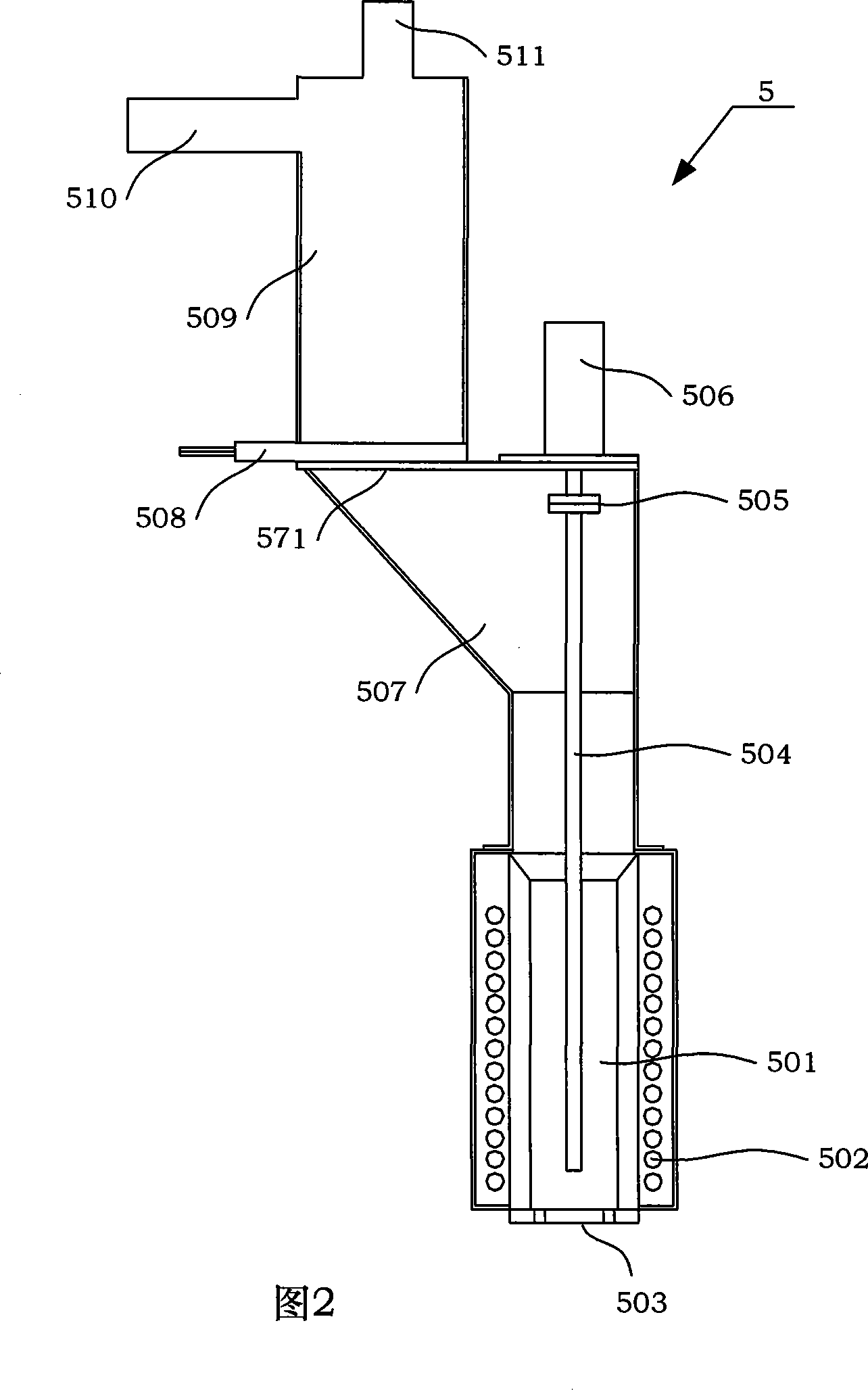

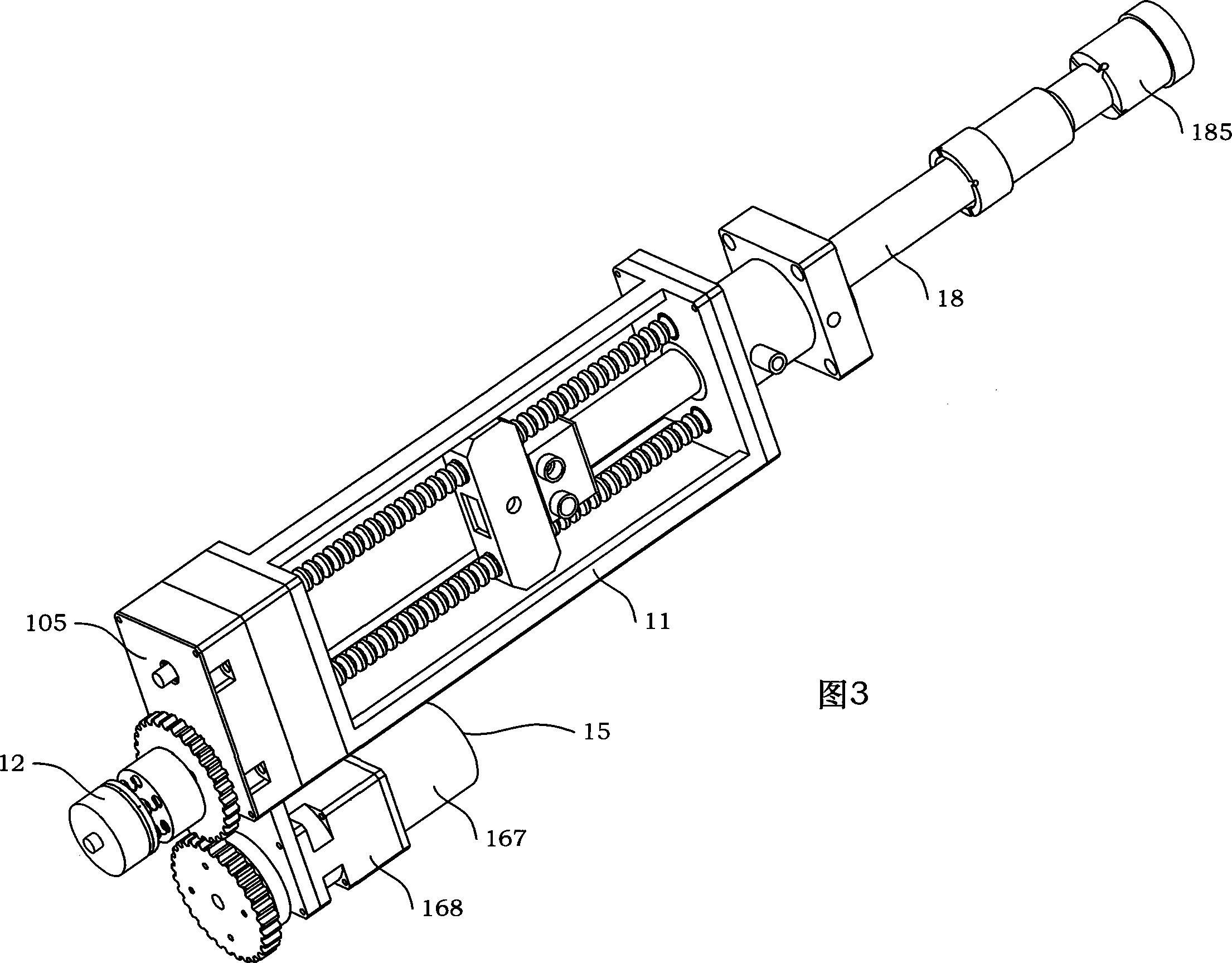

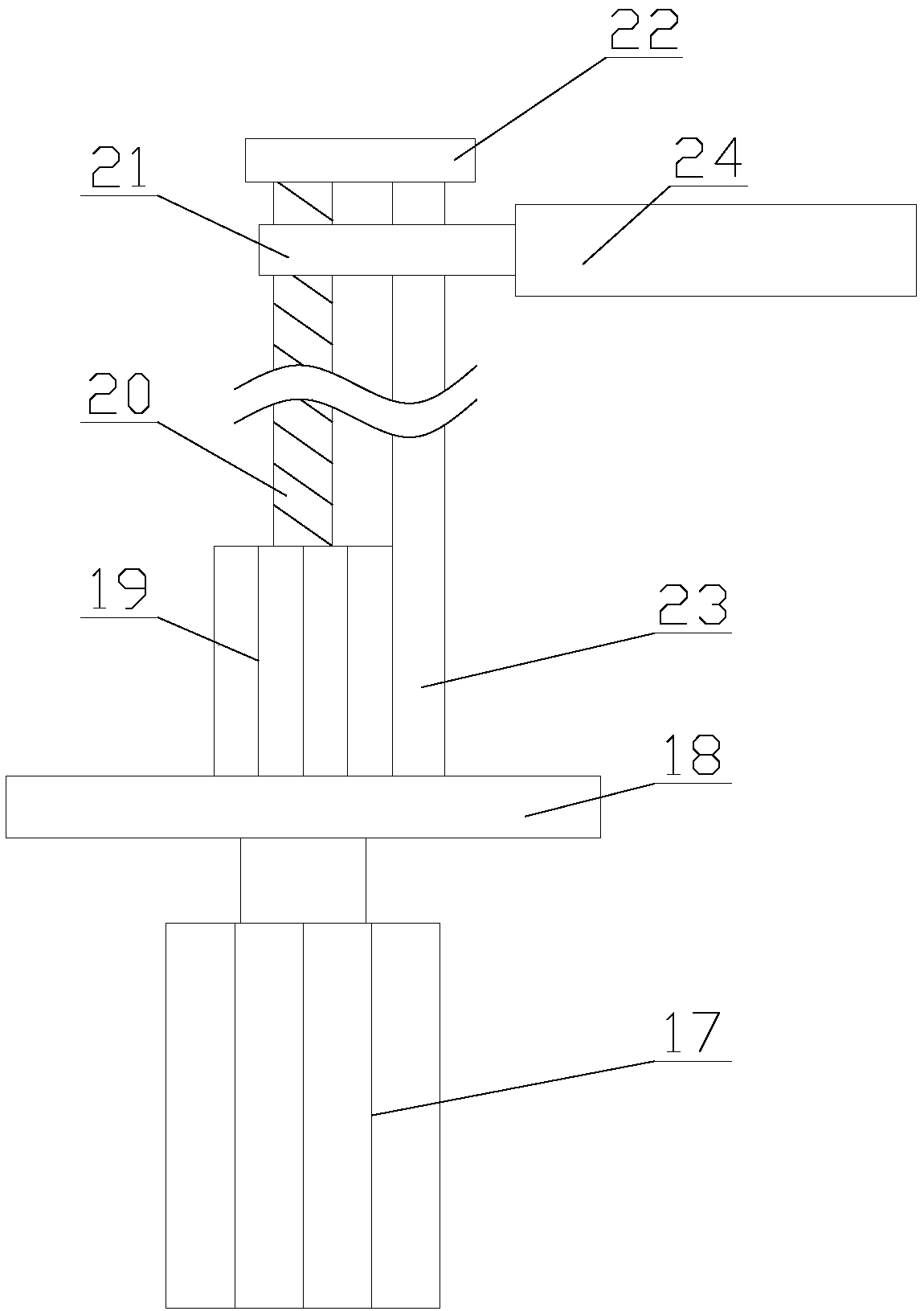

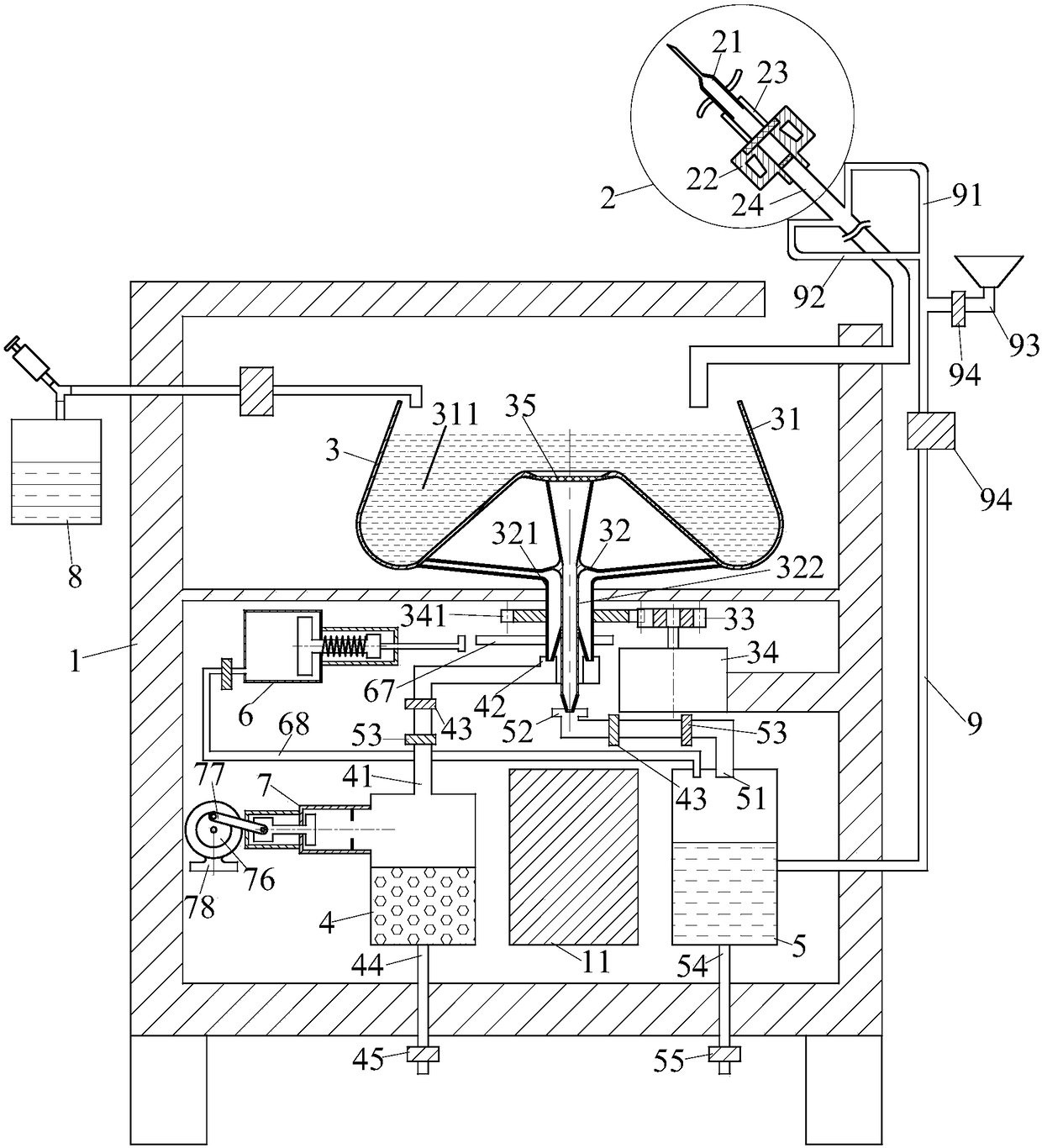

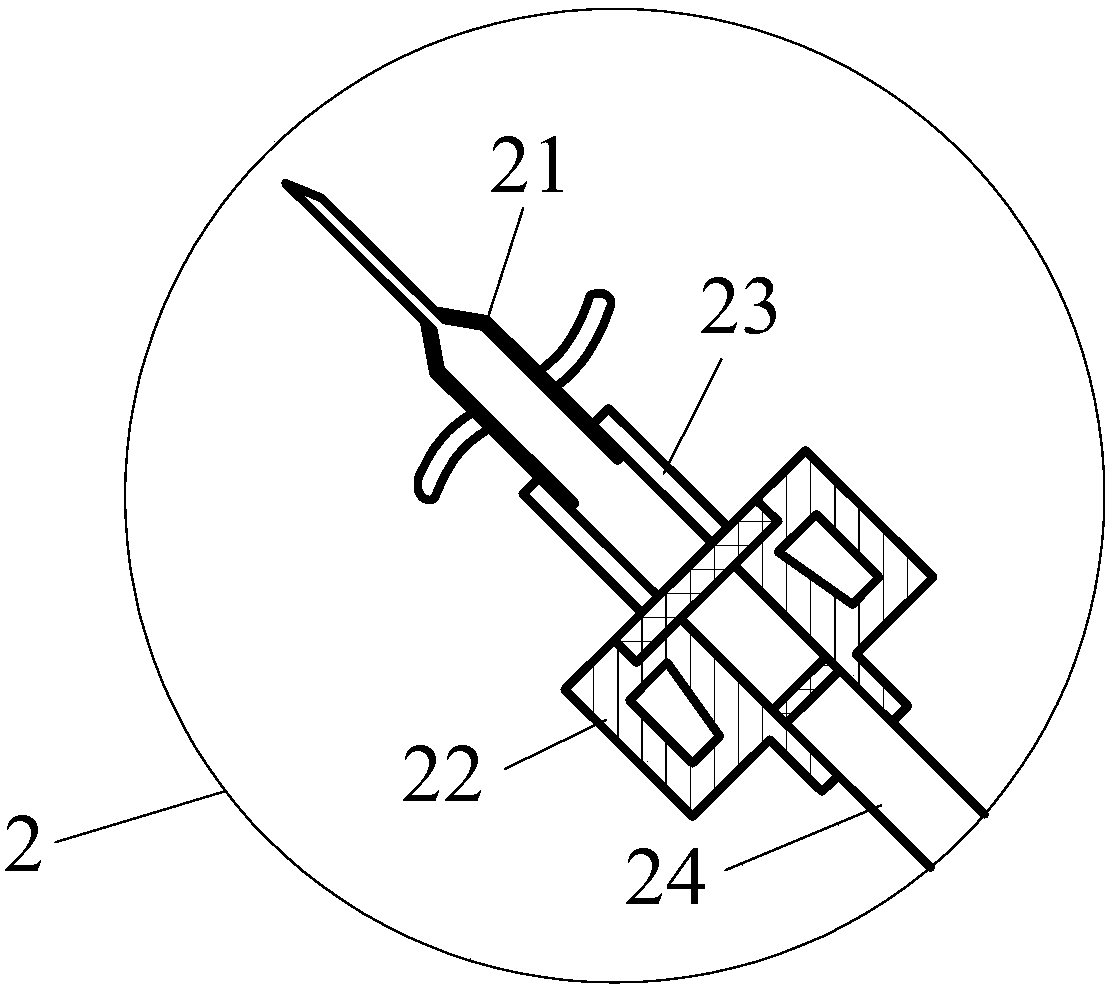

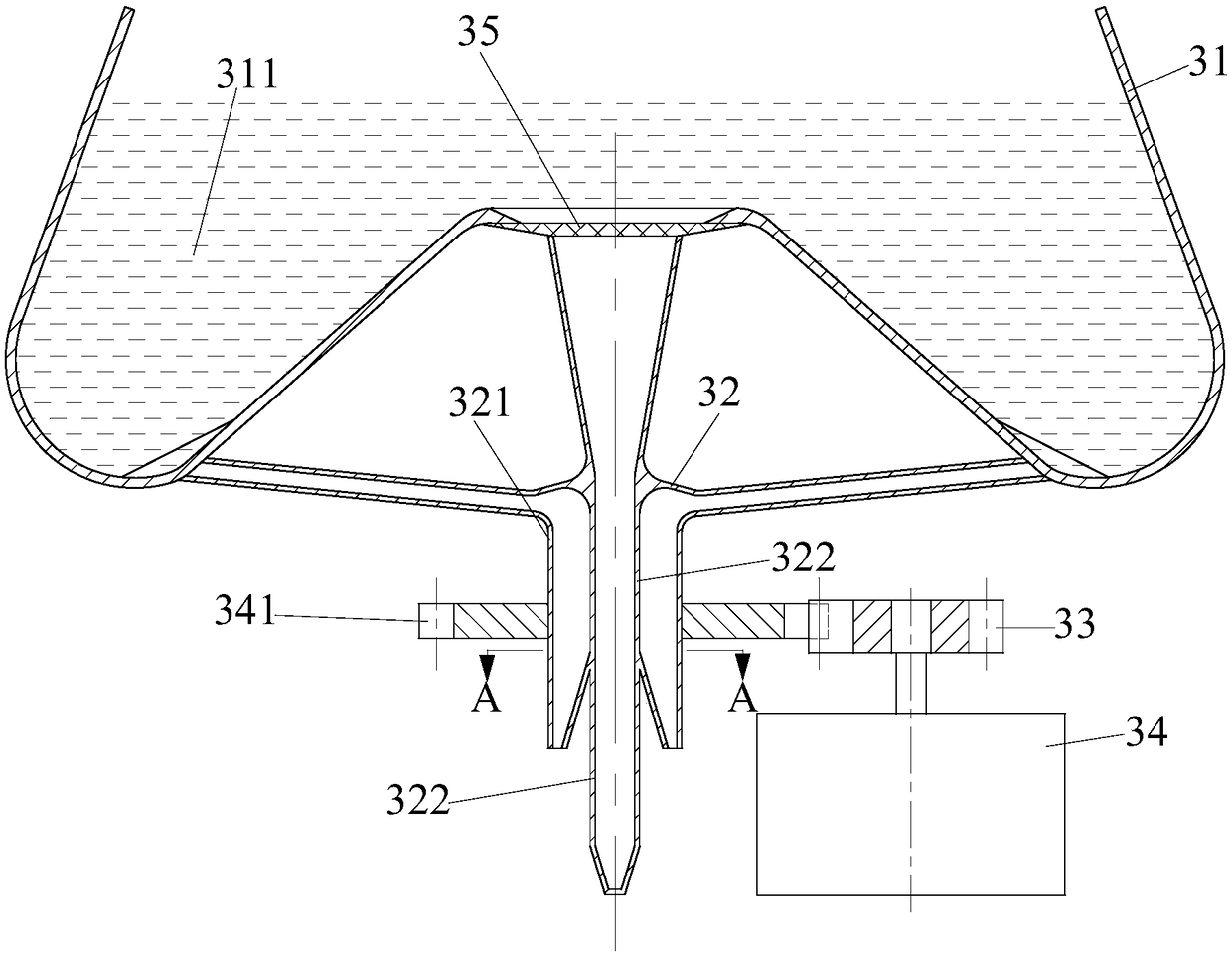

High energy beam polysilicon purifying device

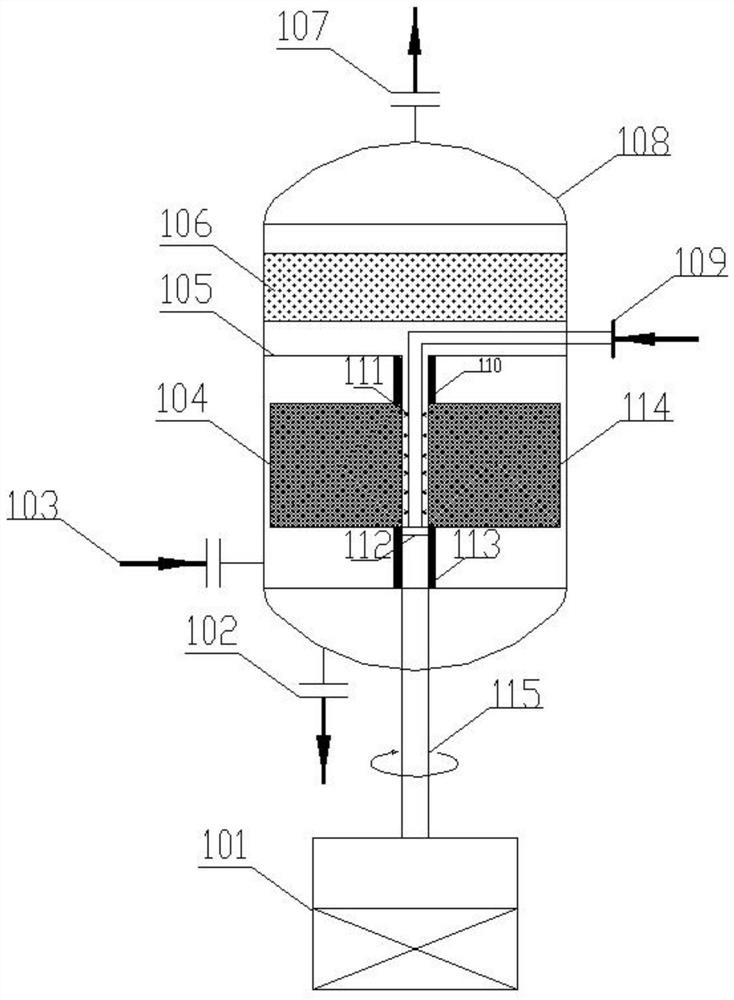

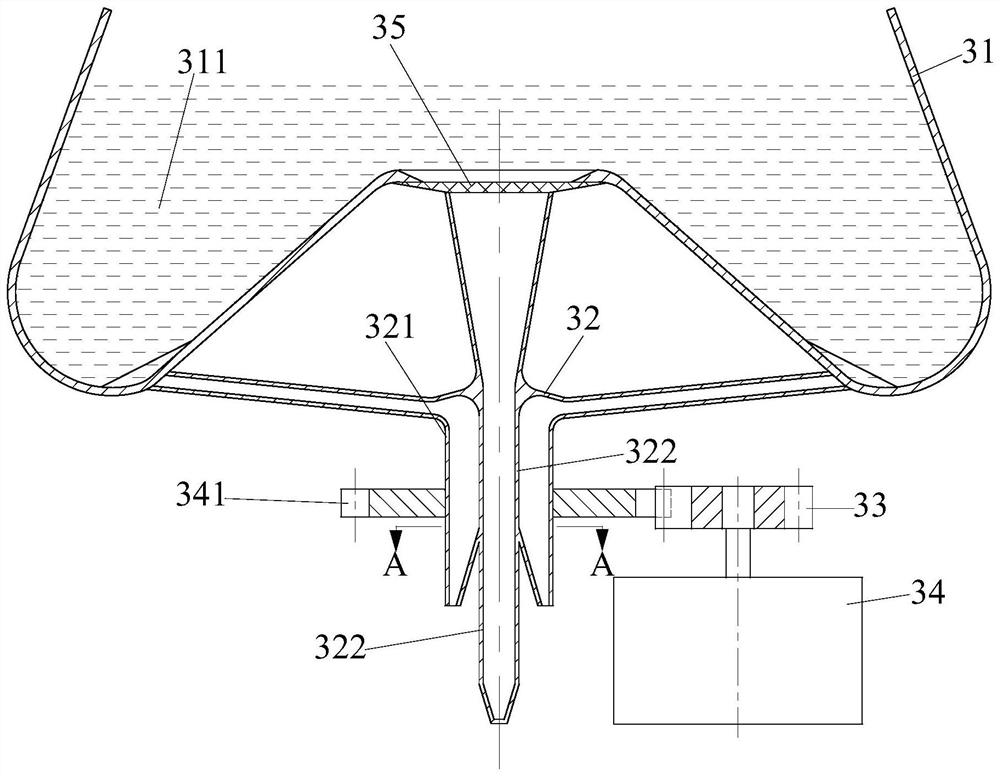

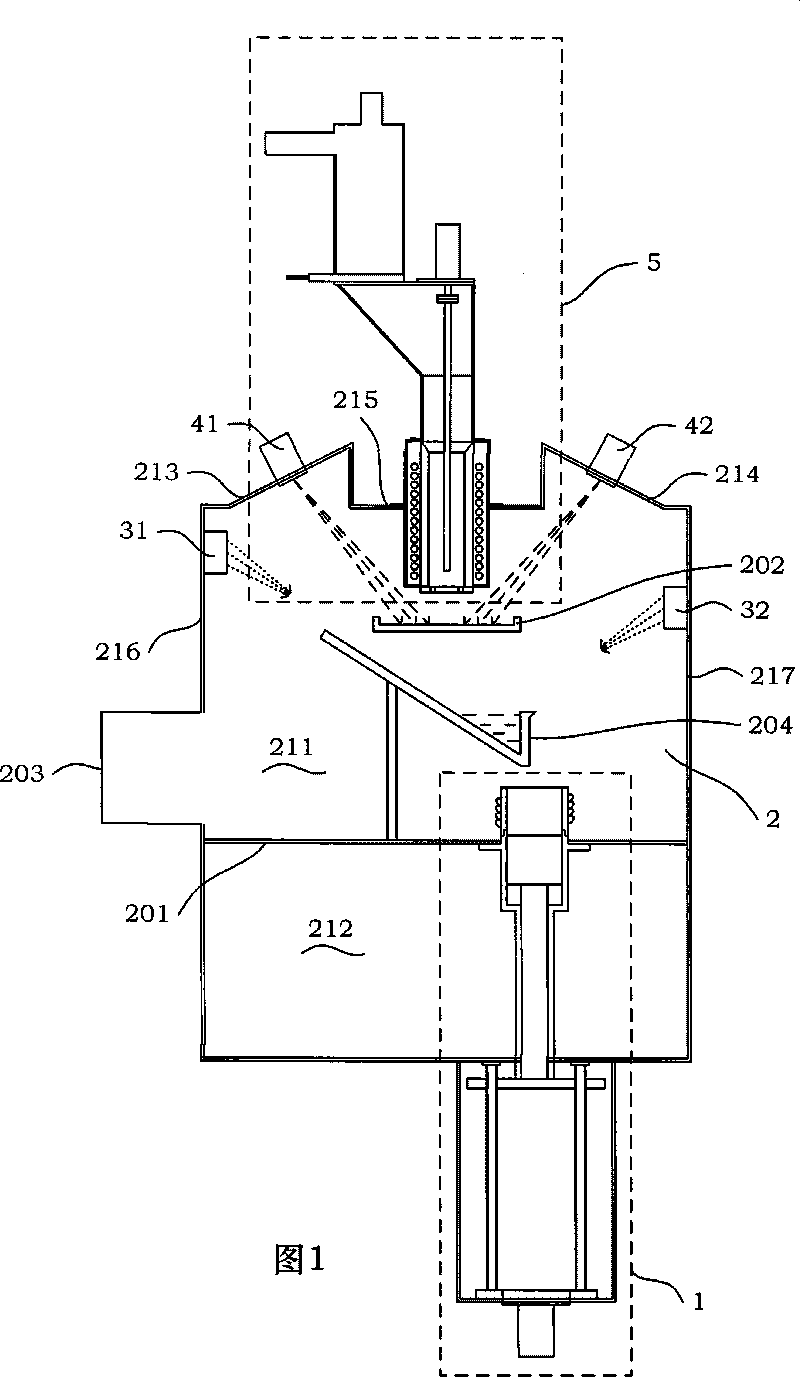

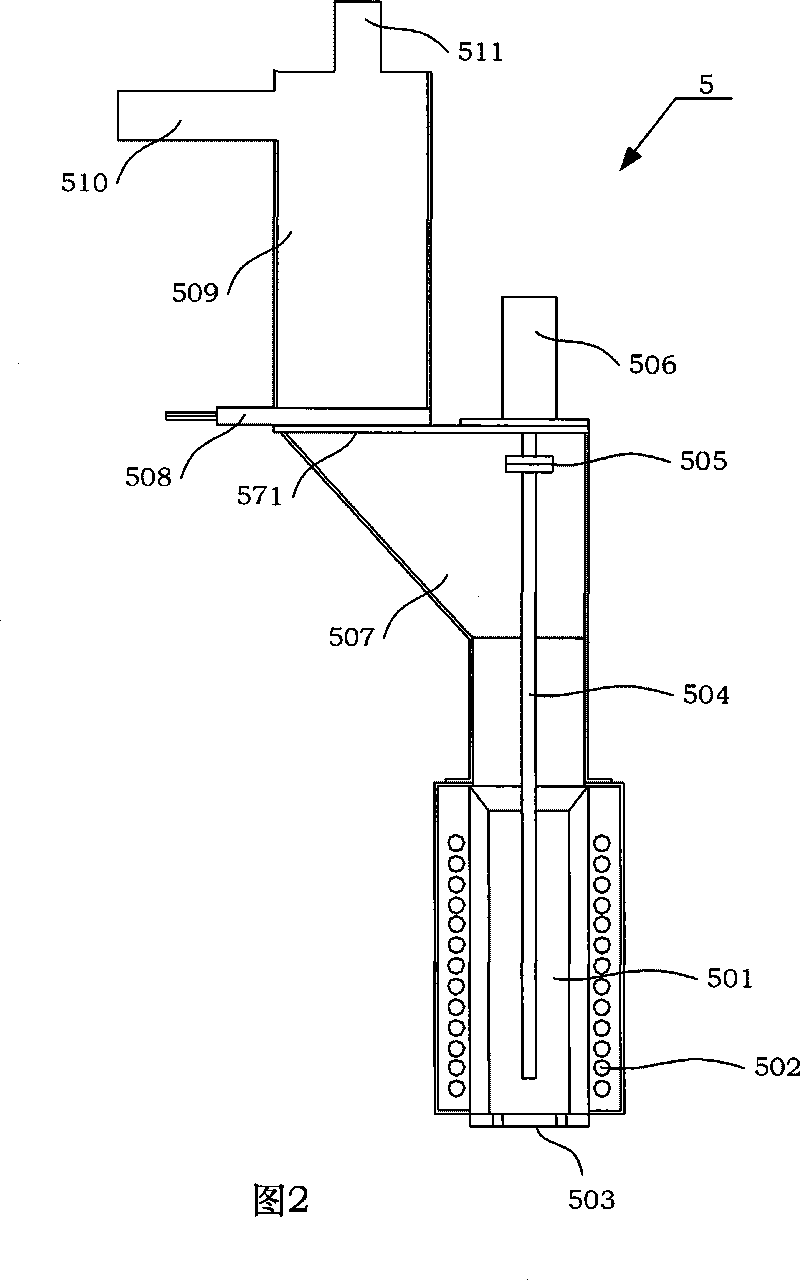

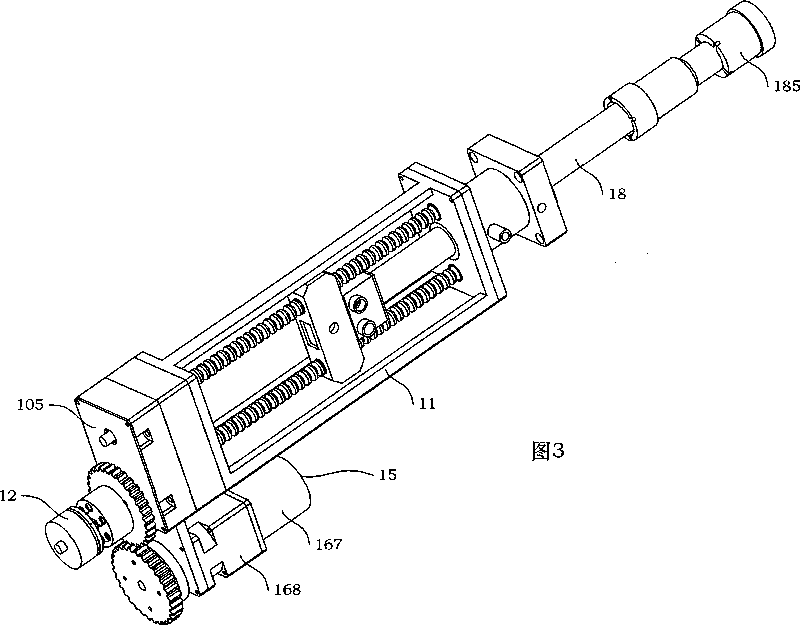

The invention discloses a device for purifying polysilicon by using a high energy beam, comprising a vacuum chamber, a vacuum electromagnetic induction smelting unit, an electron beam smelting unit, a plasma smelting unit and a directional solidification unit. The vacuum electromagnetic induction smelting unit is arranged on a concave surface of the vacuum chamber; an A electron gun of the electron beam smelting unit is arranged on a left inclined plane of the vacuum chamber and a B electron gun is arranged on a right inclined plane of the vacuum chamber; an A plasma gun of the plasma smelting unit is arranged on a left shell body of the vacuum chamber and a B plasma gun is arranged on a right shell body of the vacuum chamber; a connecting base of the directional solidification unit is arranged on a separator of the vacuum chamber; the invention aims at providing a device for purifying the polysilicon by using the high energy beam which integrates four technologies of the vacuum electromagnetic induction smelting, the plasma smelting, the electron beam smelting and the directional solidification; the purifying device carries out vacuum electromagnetic induction smelting, plasma smelting, electron beam smelting and directional solidification sequentially for silicon metal of 99.9 percent to obtain the polysilicon with a purity of 99.9999 percent which is used for producing solar batteries. The invention solves the defects of large equipment input, high cost, large energy consumption and serious environmental pollution in the prior chemical methods for producing solar grade silicon.

Owner:BEIHANG UNIV

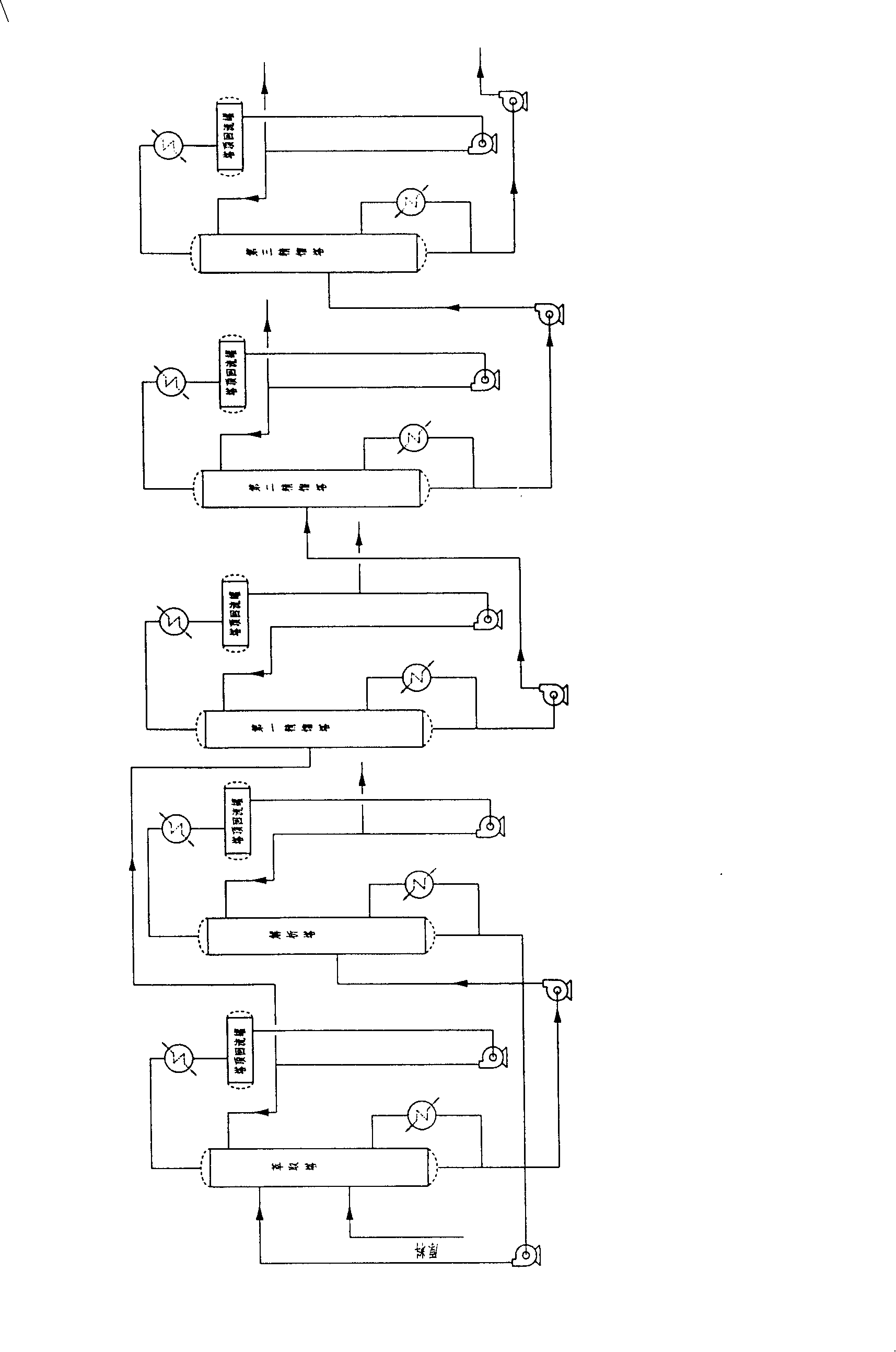

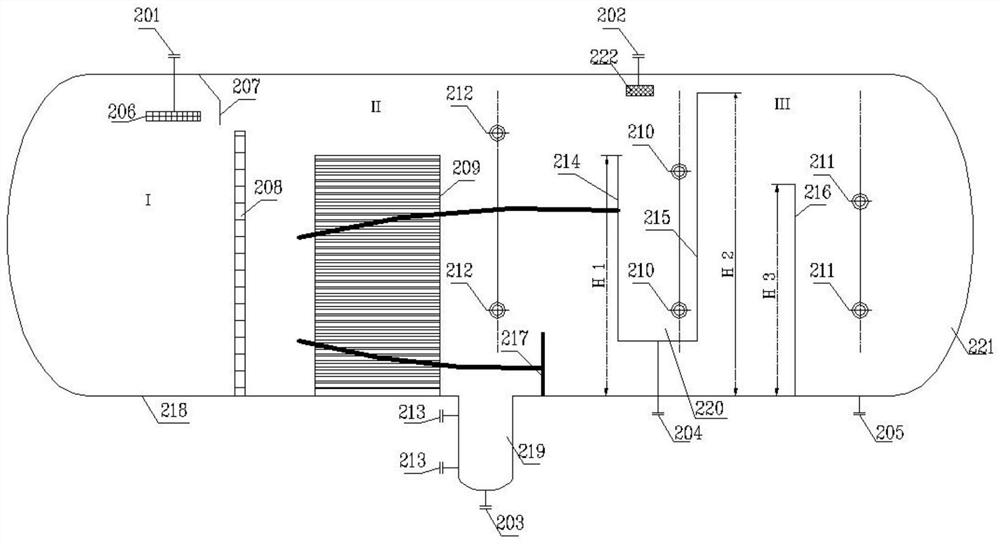

Pressure-variation adsorption separation recovering method for mixd gas containing chloroethylene and acetylene

InactiveCN1850751AAdjust or increase concentrationHigh purification precisionDispersed particle separationHalogenated hydrocarbon preparationRecovery methodSorbent

This invention relates to variable voltage absorbing separating recovery method of vinyl chloride and acetylene mixed gas. Each absorbing tower through the variable absorbing cycle process of absorbing, inverse disperse, evacuation and final boosting procedures is done. The mixed gas is processed at least two variable voltage absorbing unit, discharged gas processed by front unit in turn entering next nearby absorbing unit to get vinyl chloride and acetylene product gas. at least two absorbing tower are contained in each variable voltage absorbing unit, absorbing agent in the first tower at least contains alumina, at least one of average aperture 1-3mm silica gel or molecular sieve is contained in last variable voltage absorbing unit. This method is propitious to process mixed gas that contain more C2H3Cl and C2H2, it can make C2H3Cl and C2H2 concentrate 2-200 times, and make C2H3Cl and C2H2 be separately separated, recovered and used by the mixed gas. C2H3Cl and C2H2 in detergent effluent gas can reach environmental protection request.

Owner:四川开元科技有限责任公司

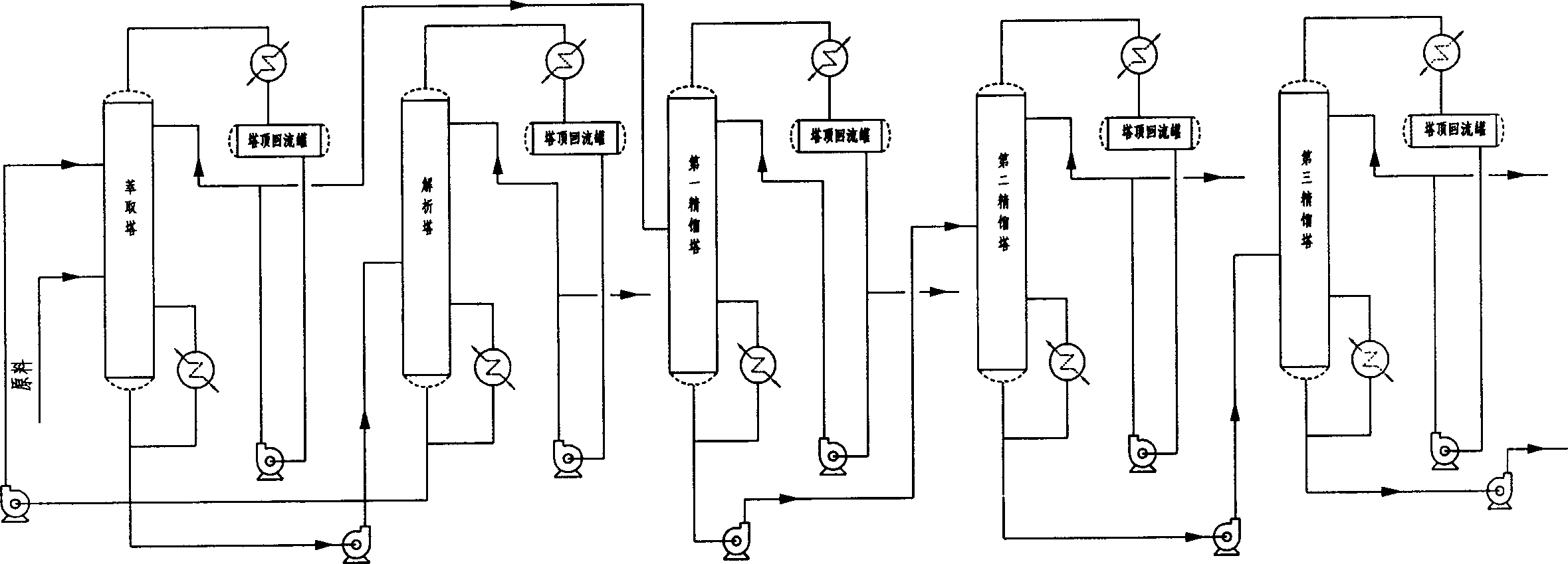

Method for producing high-purity cyclopentadiene and cyclopentane by coarse piperyene

ActiveCN1789221AChanging the relative volatilityTo achieve the effect of easy separationHydrocarbon by isomerisationCyclopenteneExtractive distillation

The invention discloses a method for preparing cyclopentene and cyclopentene of high purity by using coarse pentadiene got from petroleum cracking ethylene by-product carbon five separation. Feeding the coarse pentadiene into extraction tower in existence of polymerization inhibitor, getting mixing material of cyclopentene and cyclopentane in the tower top, extracting agent and pentadiene being in the tower still; feeding the material got in tower top to the first fractionating tower, stipping light component in tower top, getting mixing material of cyclopentene and cyclopentane in the tower still; feeding the material got from the first fractionating tower still into the second fractionating tower, getting cyclopentene of above 99% in tower top, and cyclopentane in tower still; feeding the material got from the second fractionating tower still into the third fractionating tower, steeping the heavy component in the tower still and getting the cyclopentane product in tower top. The invention employs extractive distillation method and is characterized by the high extraction accuracy, stable product quality and easy for industrial production.

Owner:山东玉皇盛世化工股份有限公司

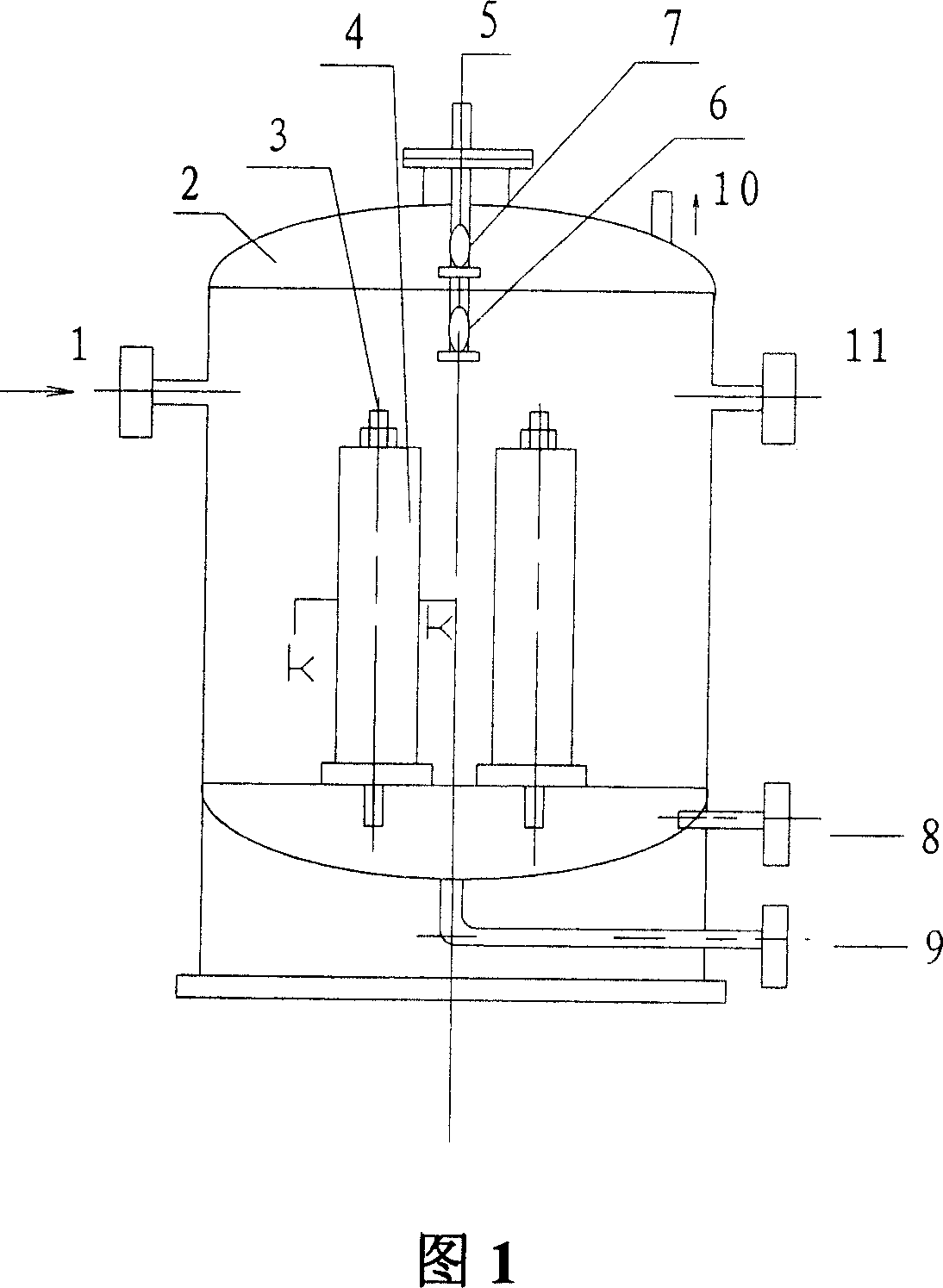

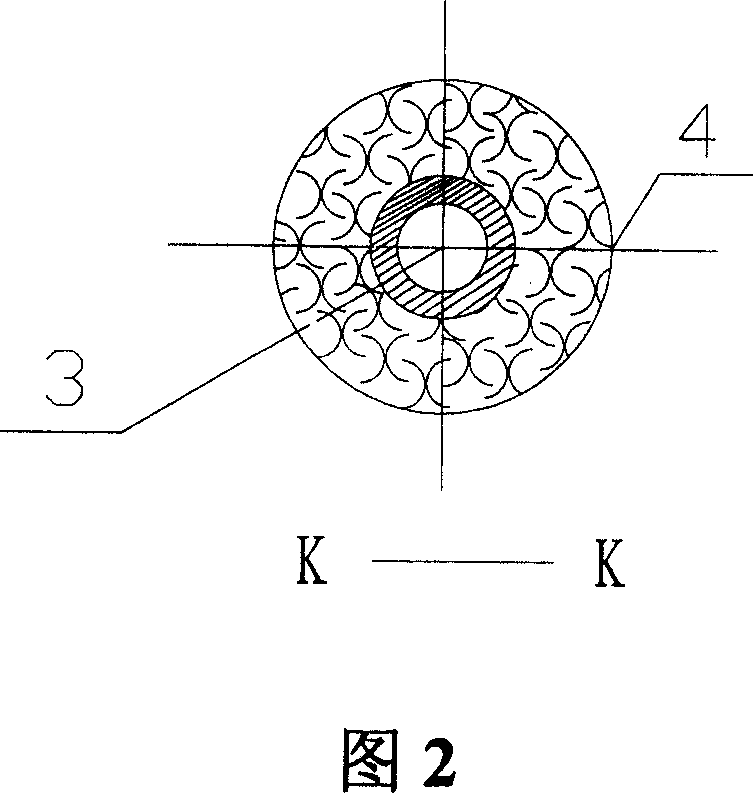

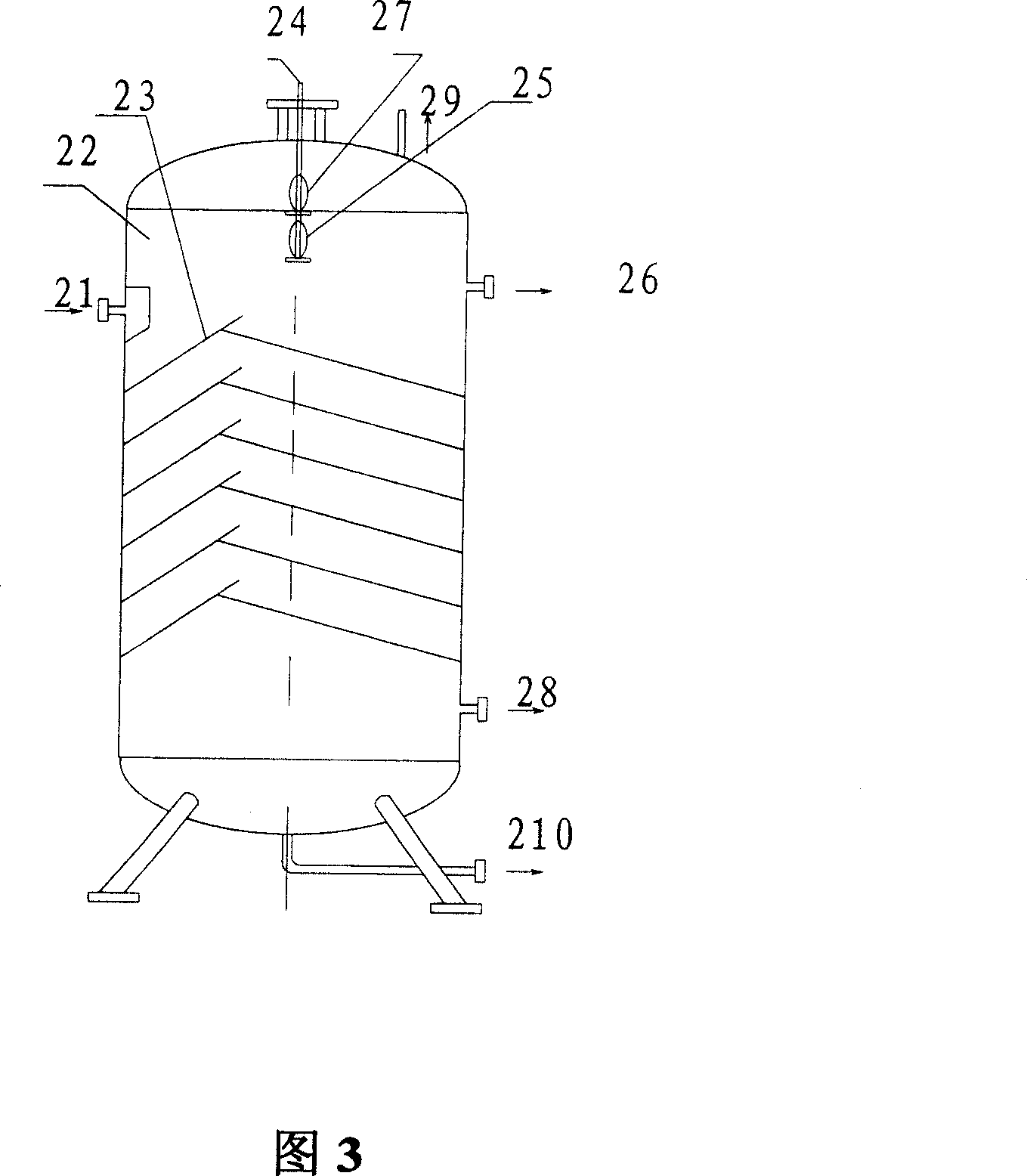

Intelligent treatment equipment of oil containing sewage

InactiveCN1948171ALow running costHigh purification precisionFatty/oily/floating substances removal devicesLiquid separationPipingEmulsion

The present invention relates to intelligent oil-containing sewage treatment equipment for cleaning oil-containing sewage. It includes an emulsion-breaking atomizer and an oil-water separator. The described emulsion-breaking atomizer is characterized by that its upper portion is equipped with a feedwater pipe, an oil-discharging pipe and a sensor, its top portion is equipped with an air-discharging pipe and its bottom portion is equipped with a liquor-discharging pipe which can be used for discharging liquor into the oil-water separator. The bottom portion of said emulsion-breaking atomizer also is equipped with a drain pipe and its centre possesses a resilient device on which a micropore tube is set. The upper portion of the above-mentioned oil-water separator is equipped with a liquor-feeding pipe, an oil-discharging pipe and a sensor, the described liquor-feeding pipe is connected with the above-mentioned liquor-discharging pipe, its top portion is equipped with an air-discharging pipe, its lower portion is equipped with a clean water pipe and its bottom portion possesses a drain pipe.

Owner:上海环宇安明消防检测技术有限公司

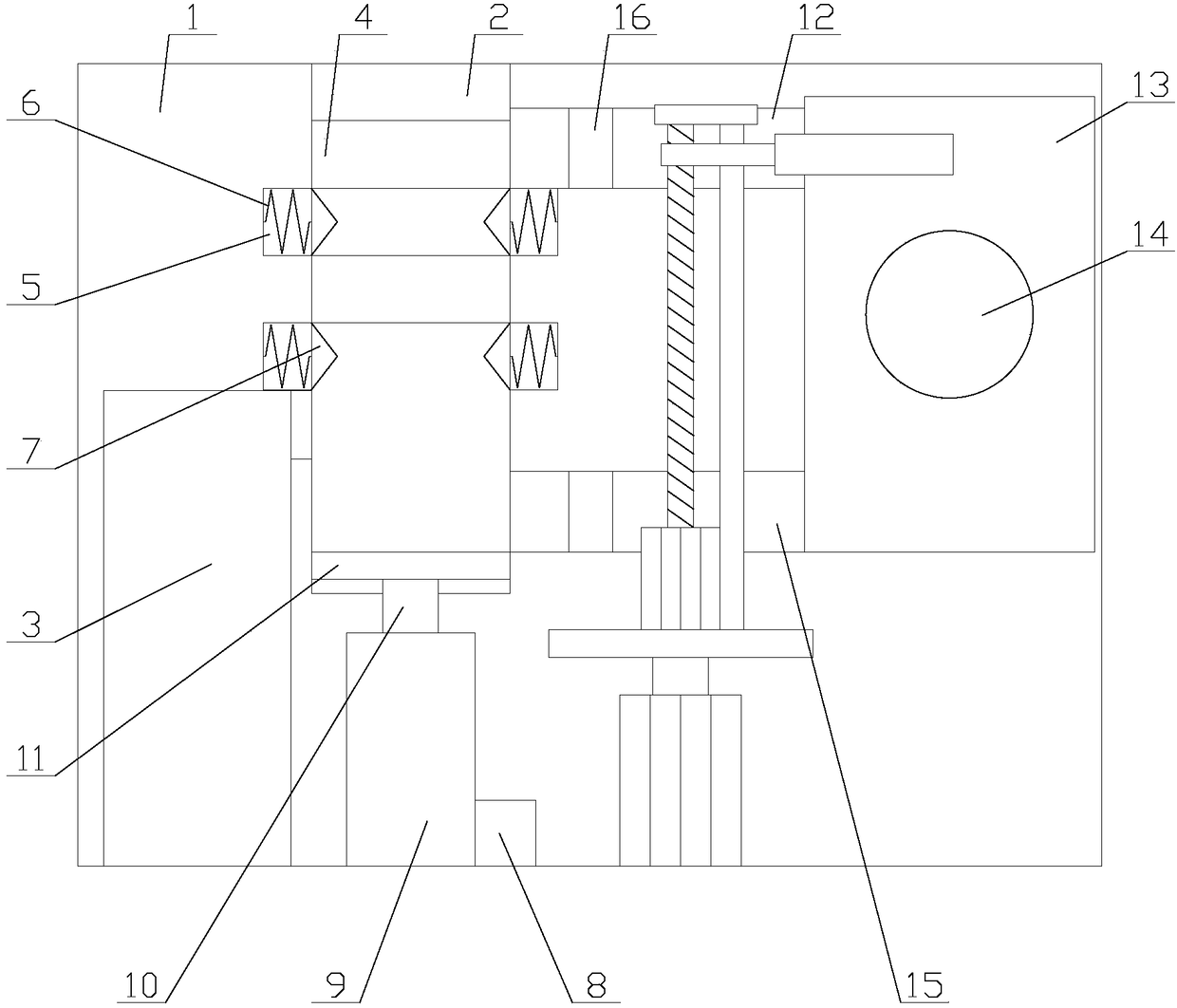

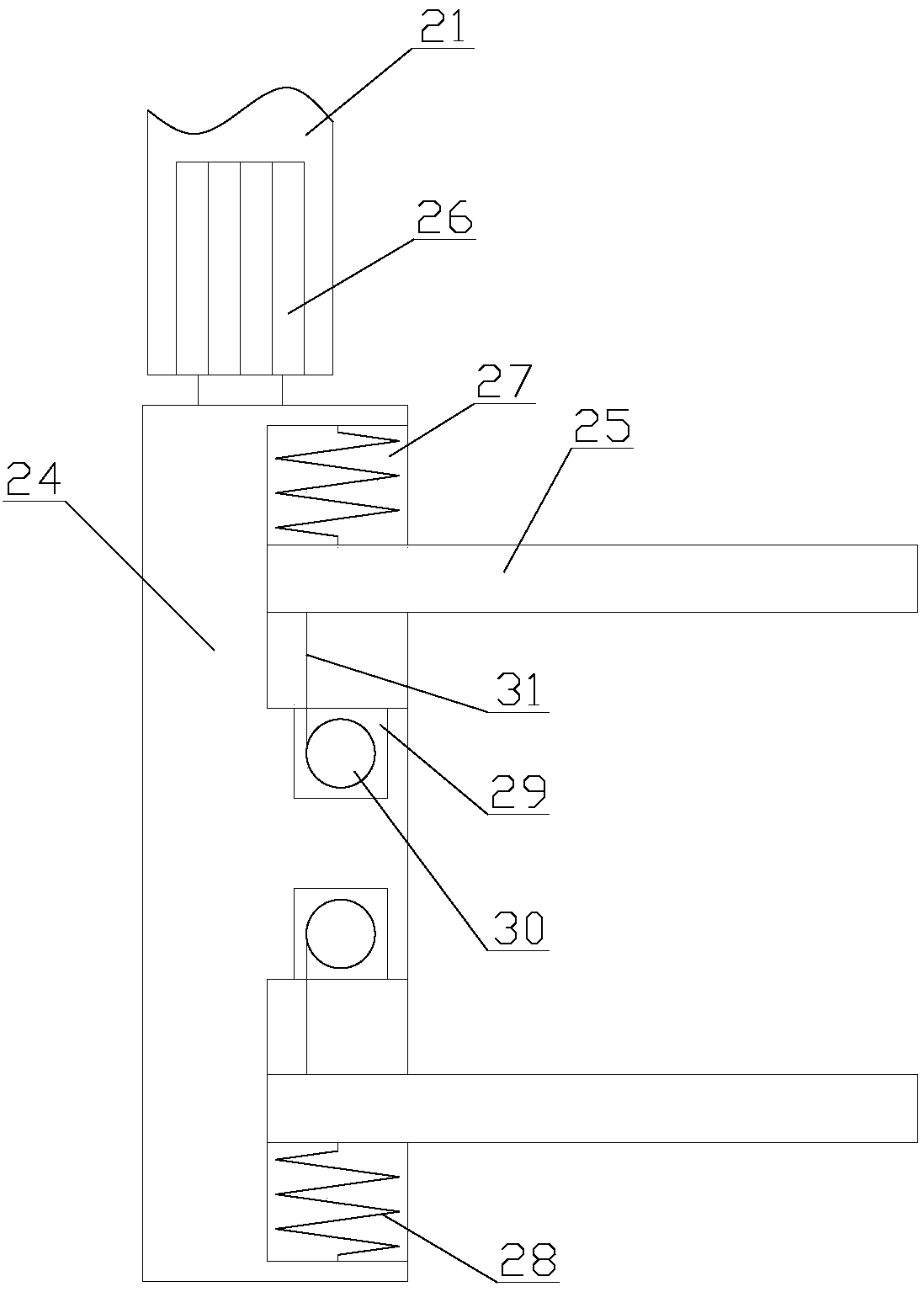

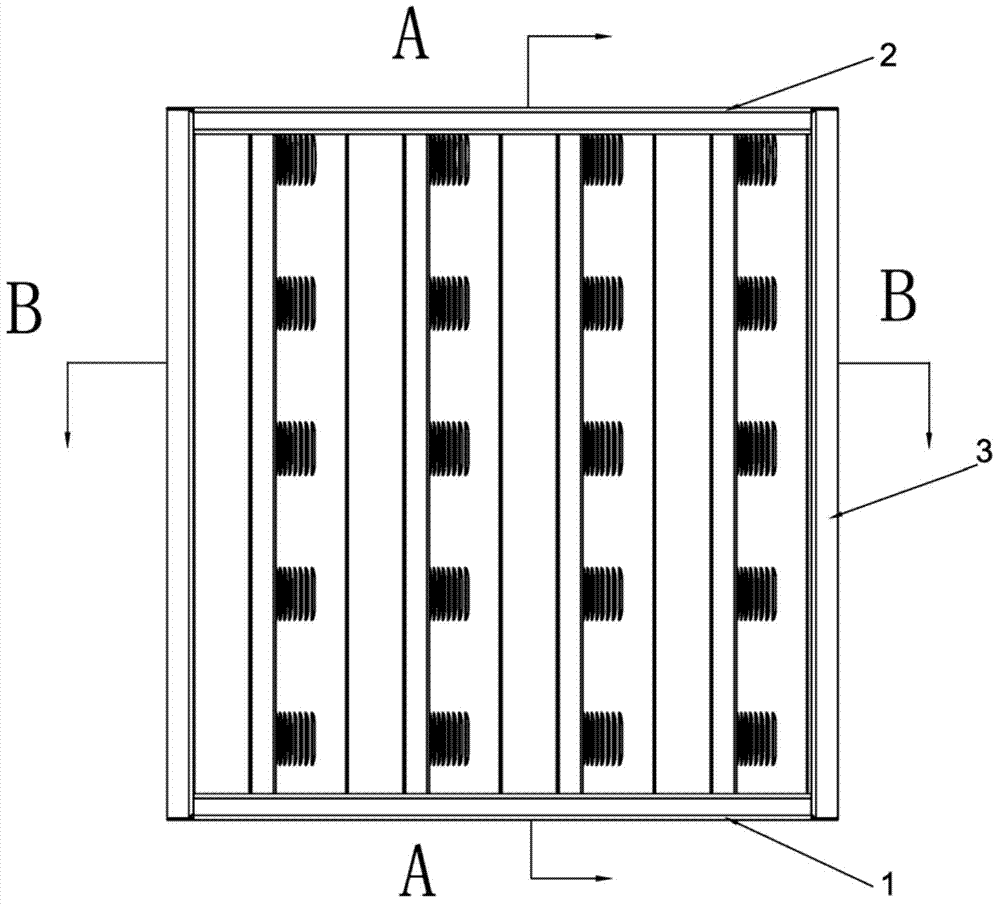

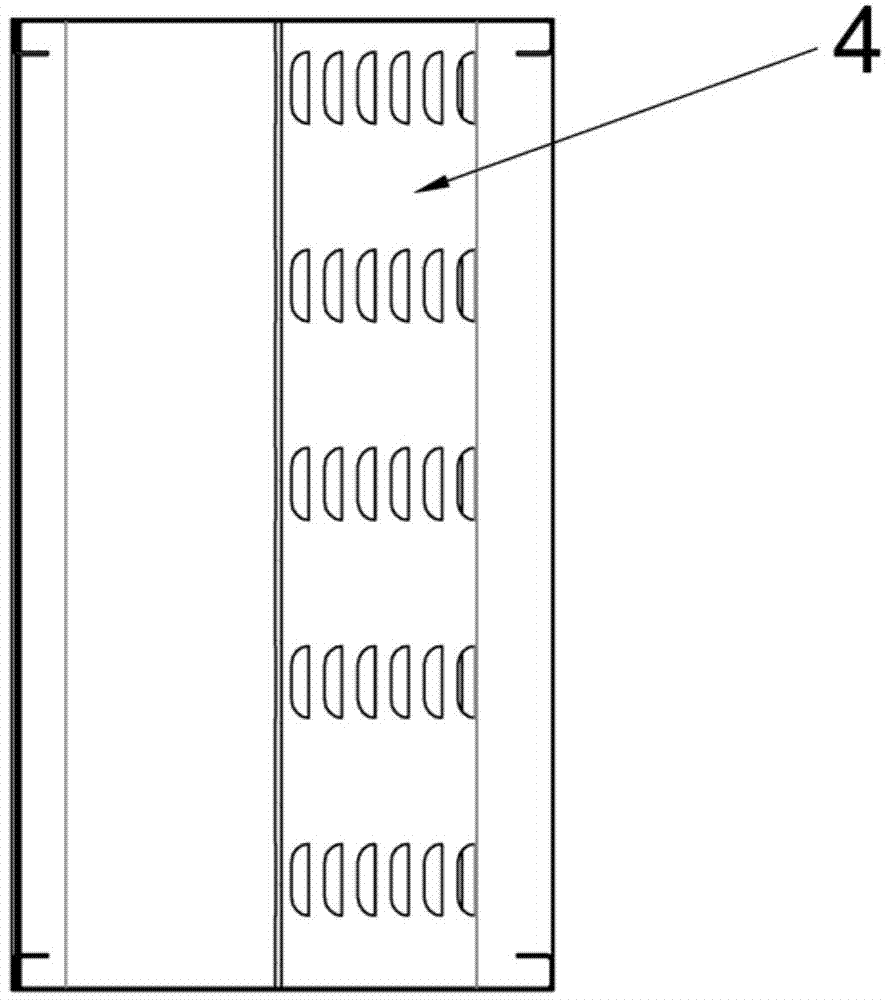

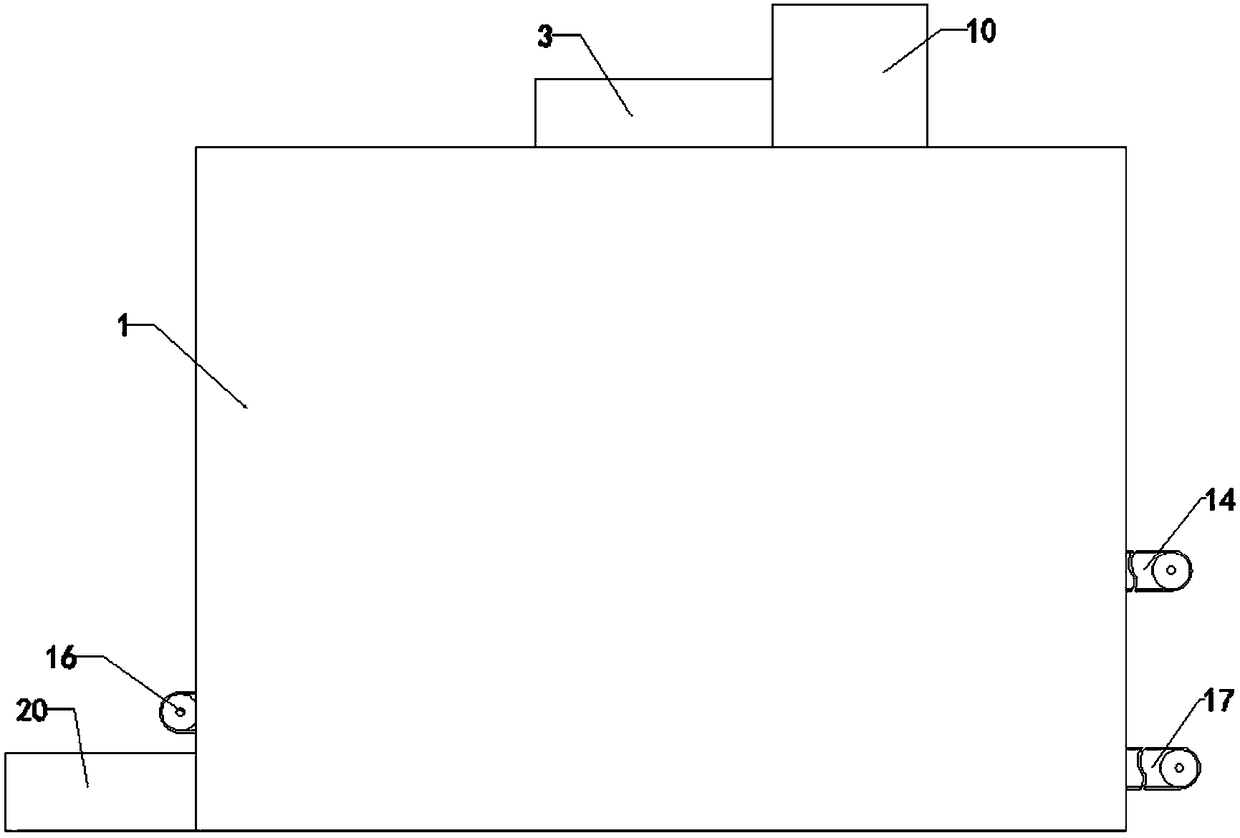

Air purification equipment with high purification precision and filter element regeneration function

InactiveCN108554169AHigh purification precisionWith filter regeneration functionDispersed particle separationActivated carbonProgrammable logic controller

The invention relates to air purification equipment with high purification precision and a filter element regeneration function. The air purification equipment comprises a main body, wherein the mainbody is internally provided with a PLC (Programmable Logic Controller), an air exhausting device, a purification pipe, a communication pipe, a regeneration box, a connection pipe, a pushing mechanismand a switching mechanism; each of the communication pipe and the connection pipe is internally provided with a stopping mechanism; the purification pipe is internally provided with two fixing mechanisms; each fixing mechanism comprises an activated carbon filter element and two locking units; the switching mechanism comprises a movable unit, a hoisting bock and a clamping unit; the movable unit comprises a first motor, a rotary table, a second motor, a screw rod and a connecting rod. According to the air purification equipment with the high purification precision and the filter element regeneration function, the activated carbon filter element at the top in the purification pipe can be moved into the regeneration box at a fixed period through the switching mechanism and harmful gas adsorbed in the activated carbon filter element is decomposed through photocatalysis; the activated carbon filter element can be regenerated; after the activated carbon filter element is discarded, the harmful gas adsorbed in the activated carbon filter element can be prevented from being volatilized to pollute the environment.

Owner:深圳讴法科技有限公司

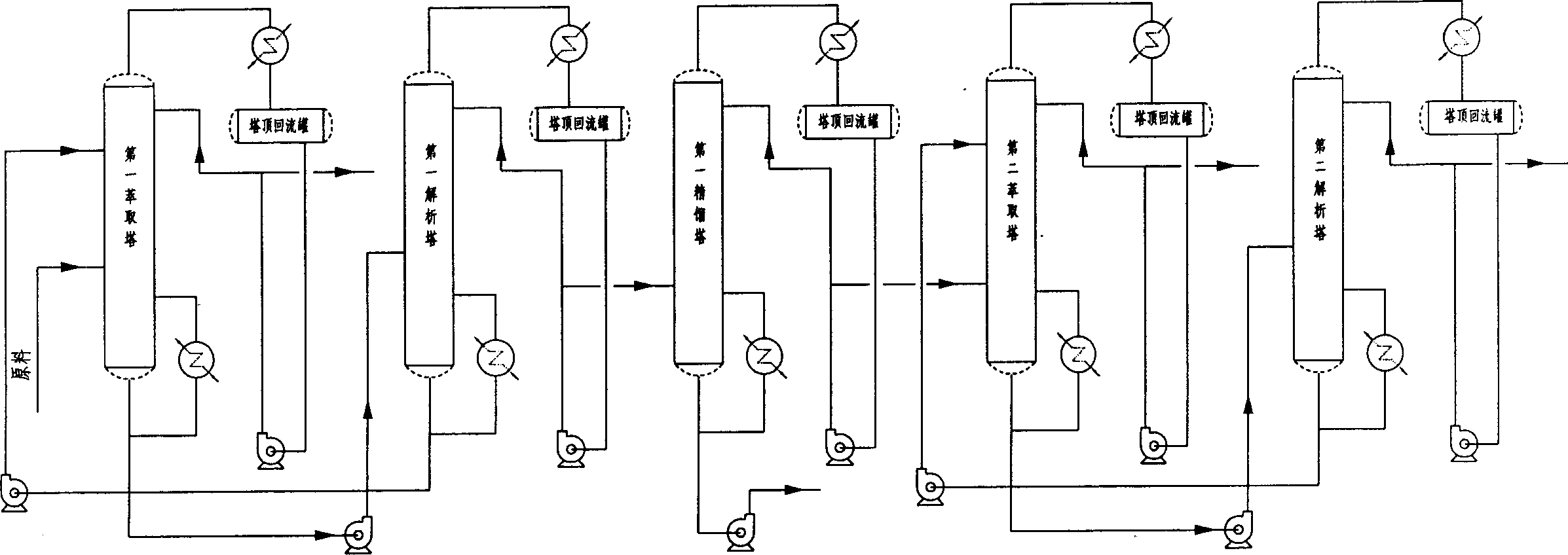

Preparation method of polymer grade piperyene

InactiveCN1789222AHigh purification precisionEase of industrial productionHydrocarbonsExtraction purification/separationExtractive distillationAlkyne

The invention discloses a method for preparing polymer grade pentadiene. Feeding the raw material of pentadiene into the first extraction tower in existence of polymerization inhibitor, getting extracting agent and pentadiene in tower still; feeding the material got in the first extraction tower into the first analysizing tower, getting pentadiene of high purity containing cyclopentadiene and alkyne; feeding the high pure pentadiene into fractionating tower, getting pentadiene of high purity containinging little amount of cyclopentadiene and alkyne in tower top; feeding the material gor in fractionating tower top into the second extraction tower in existence of polymerization inhibitor 731, getting pentadiene in tower top, feeding the extraction agent, cyclopentadiene and alkyne in tower still into the second analyzing tower; stripping cyclopentadiene and alkyne in the second analyzing tower top, the extraction agent in tower still being returned to the second extraction tower for recyclic use. The invention employs the second-time extractive distillation method, preparing pentadiene from raw material, and is characterized by high extraction accuracy and easy for industrial production.

Owner:SHANDONG YUHUANG CHEM CO LTD

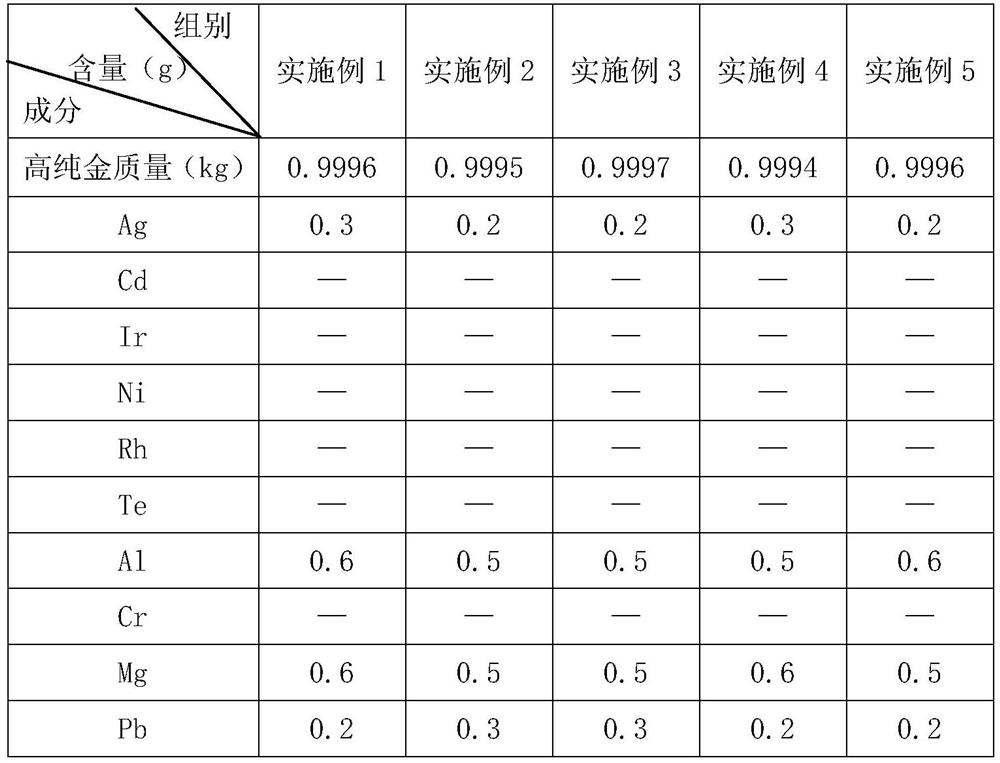

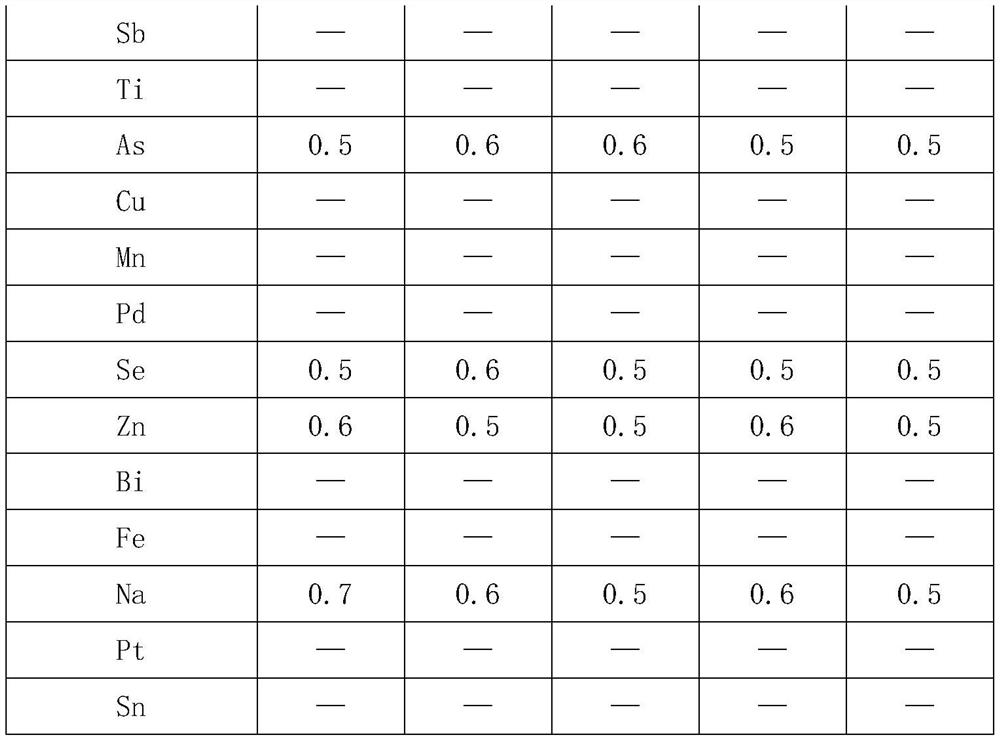

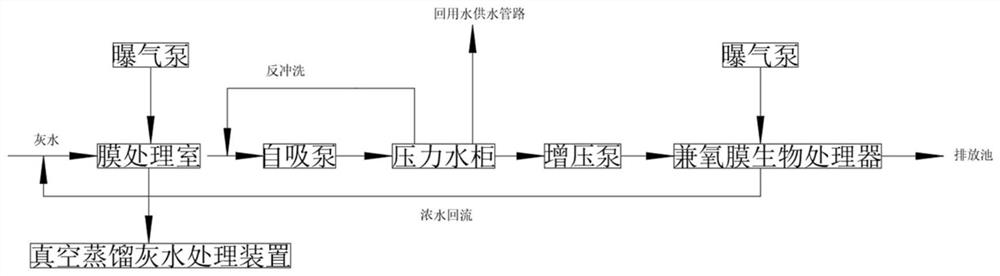

Production process of high-purity gold

InactiveCN112210674AConducive to efficient and high-quality productionImprove securityIngot castingAqua regia

The invention discloses a production process of high-purity gold, and relates to the technical field of metal refining. The production process comprises the following steps that: S1, gold is dissolvedin aqua regia, wherein crude gold is added to aqua regia and dissolved to make a solution, and after nitrate is removed, filtering is conducted to obtain a crude gold solution; S2, reduction is conducted, wherein a reducing agent is added to the crude gold solution obtained in S1, filtering is conducted to obtain primary fine gold powder, and the primary fine gold powder is washed with pure wateruntil the primary fine gold powder is neutral; S3, acid leaching is conducted, wherein the primary fine gold powder obtained in S2 is put into a nitric acid solution, soaked and then filtered, and pure fine gold powder is obtained; and S4, gold smelting is conducted, wherein the pure fine gold powder obtained in S3 is washed with pure water, dried, inspected, and used for preparing the high-purity gold product through ingot casting after being inspected to be qualified. The production process has the technical effects of high production safety, short process flow period and good controllability.

Owner:深圳市点金贵金属精炼有限公司

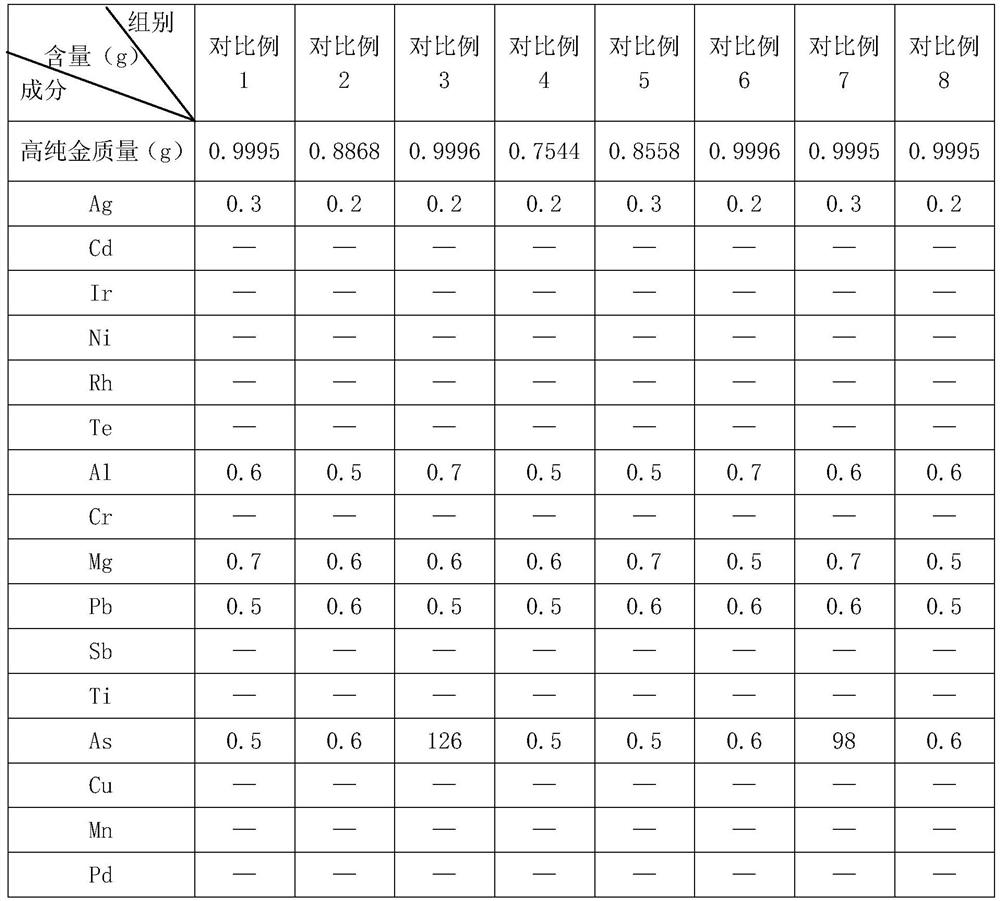

New technology and system for preparing high-purity carbon monoxide by temperature control transformation

The invention discloses a new technology and a system for preparing high-purity carbon monoxide by temperature control transformation and a system. The new technology includes the steps: buffering storage, compressing water rings, exhausting dust by a wet method, compressing gas, firstly purifying, secondly purifying, desorbing CO2, concentrating CO, refining CO and filling. By the new technology, feed gas is roughly purified by temperature control transformation to refine carbonic oxide, the new technology solves the problem of high cost of a traditional refining method of formamide decomposition, formic acid decomposition and the like and is simple in refining process, high in refining precision, low in cost and convenient to use.

Owner:茂县鑫新能源有限公司

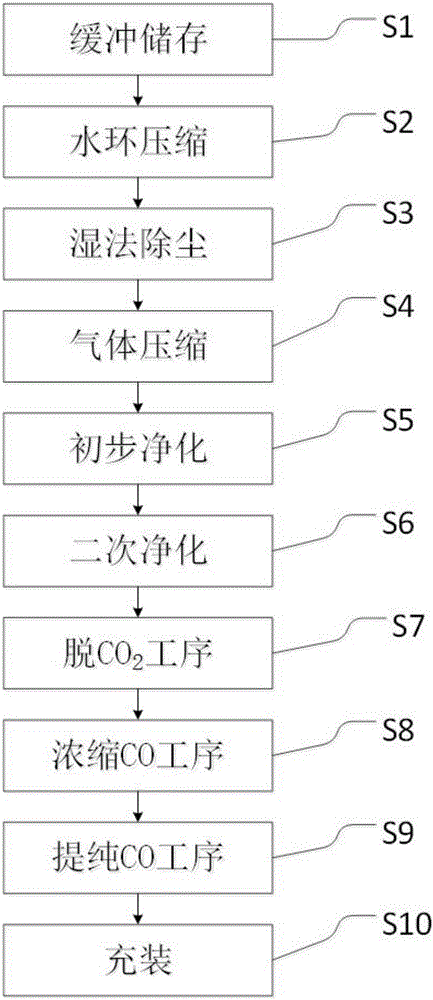

Method for treating ship grey water by facultative membrane bioreactor technology

PendingCN112851038AReduce the amount of sewageEasy to handleWater treatment parameter controlWater contaminantsBiologyGreywater

The invention discloses a method for treating ship grey water by a facultative membrane bioreactor technology, and relates to the technical field of ship grey water treatment. The problem of sludge in the membrane bioreactor is solved. The method specifically comprises the following steps: ship grey water enters a membrane treatment chamber, the grey water is pretreated through an ultrafiltration membrane assembly in the membrane treatment chamber, the grey water is pumped into a pressure water tank under the action of a self-priming pump, the pretreated grey water in the pressure water tank enters a facultative membrane bioreactor through a booster pump, the interior of the facultative membrane bioreactor is divided into membrane module areas of an upper group and a lower group, the upper part is an aerobic type membrane module, the lower part is a mixed type membrane module, the grey water firstly enters the upper membrane module, and the aerobic type microorganisms carry out aerobic nitration and aerobic phosphorus uptake on the grey water. The sewage amount is greatly reduced, the treated distilled water can be recycled, the treatment process is simple and efficient, secondary pollution is avoided, and dirt accumulation on the surface of the membrane is effectively prevented.

Owner:江苏航运职业技术学院

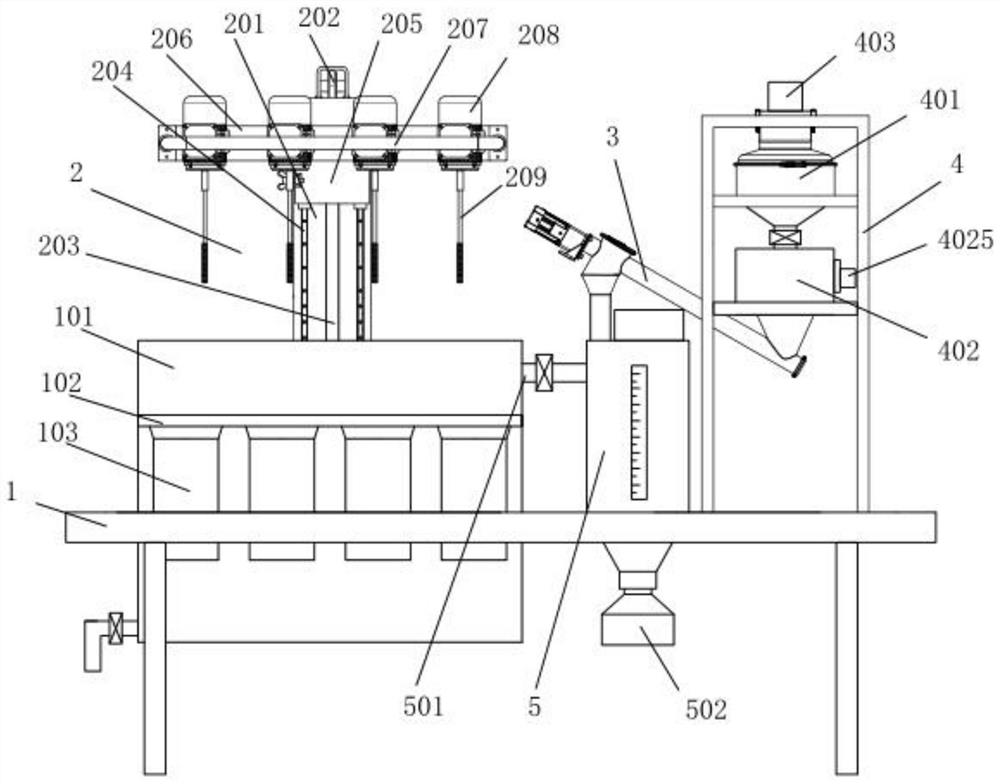

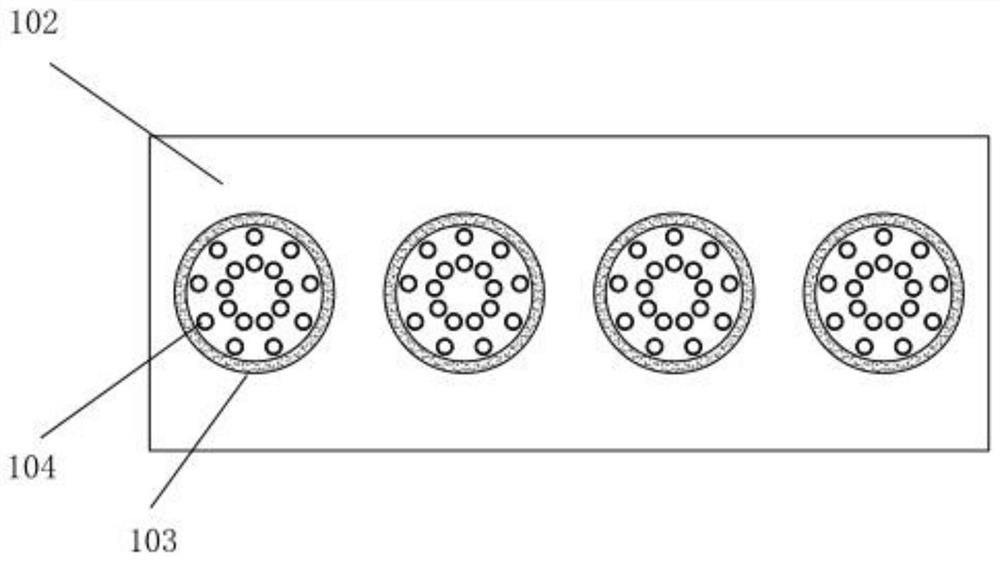

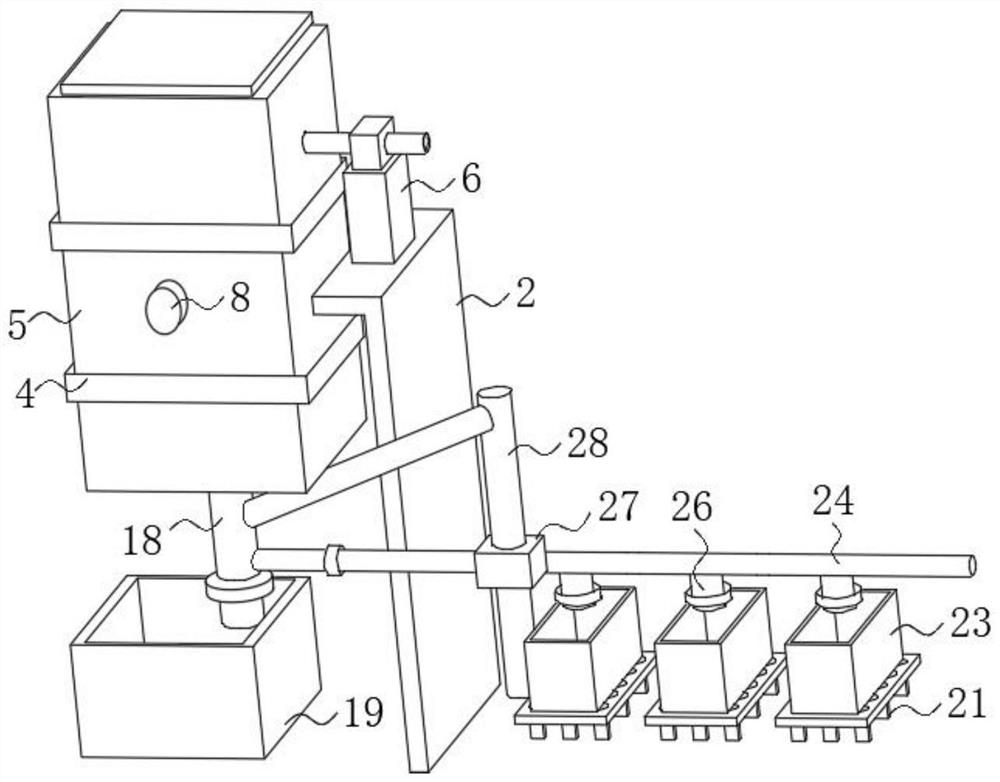

Lead paste purification equipment for lead-acid battery recovery and purification method of lead paste purification equipment

ActiveCN113328163AImprove precipitation qualityReduce shockFinal product manufactureWaste accumulators reclaimingPurification methodsProcess engineering

The invention discloses lead paste purification equipment for lead-acid battery recovery and a purification method of the lead paste purification equipment. The lead paste purification equipment comprises a workbench, a purification box is fixedly arranged on the table top of the workbench, a material taking mechanism is fixedly arranged on one side of the back face of the workbench and located above the purification box, and a spiral conveyor, a feeding frame and a feeding tank are arranged on the right side of the workbench; the feeding end of the spiral conveyor is connected with a discharging port of the feeding frame, the discharging end of the spiral conveyor is connected with a feeding port of the feeding tank, and the feeding tank is connected with the purification box through a communicating pipe. A plurality of purification cavities are formed in the purification box, purification frames are arranged in the purification cavities, and a plurality of purification cylinders are arranged on the purification frames; in other words, a flocculating agent is added into the purification box, so that the lead plaster solution enters the purification cylinder in the purification box, precipitation of the lead plaster solution is realized in the purification cylinder, precipitation of the lead plaster in the purification box belongs to an independent environment is realized, oscillation is reduced, and purification precision is improved.

Owner:太和县大华能源科技有限公司

Method for producing high-purity cyclopentadiene and cyclopentane by coarse piperyene

ActiveCN100393676CIncrease added valueChanging the relative volatilityHydrocarbon by isomerisationCyclopenteneExtractive distillation

The invention discloses a method for preparing cyclopentene and cyclopentene of high purity by using coarse pentadiene got from petroleum cracking ethylene by-product carbon five separation. Feeding the coarse pentadiene into extraction tower in existence of polymerization inhibitor, getting mixing material of cyclopentene and cyclopentane in the tower top, extracting agent and pentadiene being in the tower still; feeding the material got in tower top to the first fractionating tower, stipping light component in tower top, getting mixing material of cyclopentene and cyclopentane in the tower still; feeding the material got from the first fractionating tower still into the second fractionating tower, getting cyclopentene of above 99% in tower top, and cyclopentane in tower still; feeding the material got from the second fractionating tower still into the third fractionating tower, steeping the heavy component in the tower still and getting the cyclopentane product in tower top. The invention employs extractive distillation method and is characterized by the high extraction accuracy, stable product quality and easy for industrial production.

Owner:山东玉皇盛世化工股份有限公司

Gas filter applicable to float type pneumatic measuring instrument

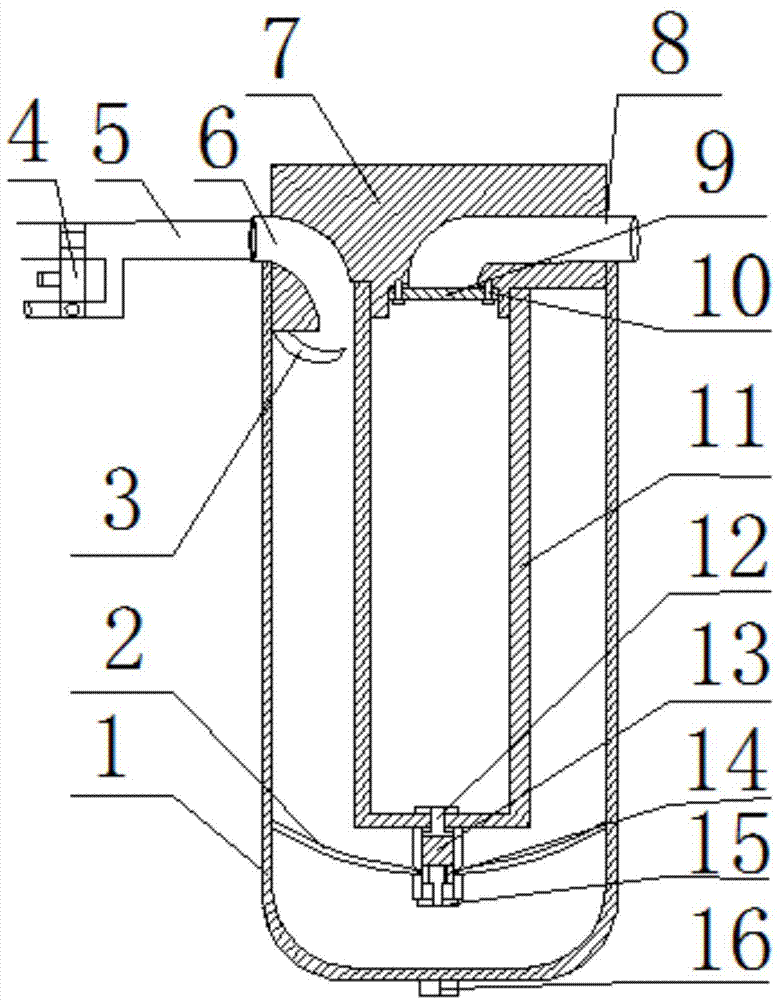

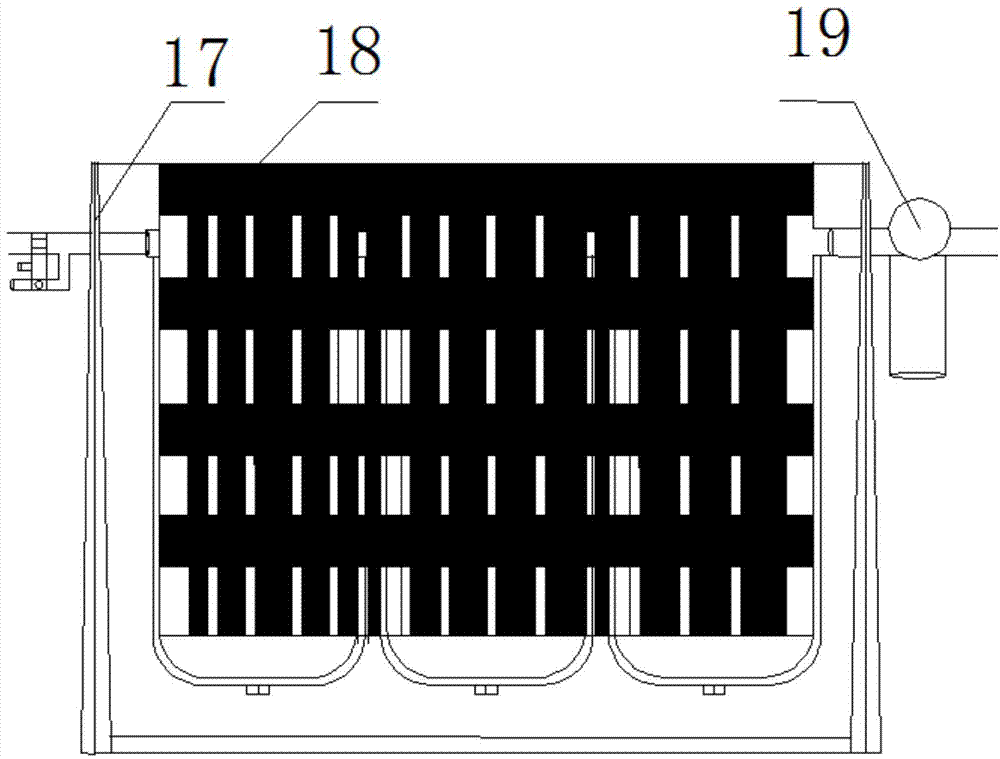

InactiveCN103933791AProtect interestsIncreased design featuresDispersed particle filtrationWater storageWater discharge

The invention discloses a gas filter applicable to a float type pneumatic measuring instrument. The gas filter comprises a gas filter shell, a water guide plate, a flow guide plate, a multifunctional switch, a gas pipe, a gas source input joint, a gas filter shell cover, a gas source output joint, a filtration plate, a bolt, a filter element, an upper hollow bolt, a sliding block, a spring, a lower hollow bolt, a water discharging bolt, a bracket, an anti-explosion plate and a pressure gage. The gas filter is characterized in that the multifunctional switch is arranged; when the multifunctional switch is in one position, gas enters the gas filter through the switch; after the multifunctional switch is rotated by 180 degrees, the gas filter is connected with the atmosphere, the water flows into a water storage chamber from the gas filter; the gas is filtered for three times in the gas filter through crude, middle and high filtration cups of the filter element and the filtration plate; the anti-explosion plate is capable of effectively avoiding the harm to the human body and equipment when accidents happen; and three filters which are connected in series can guarantee the quality of the filtered air.

Owner:山东国运量仪精密机械有限公司

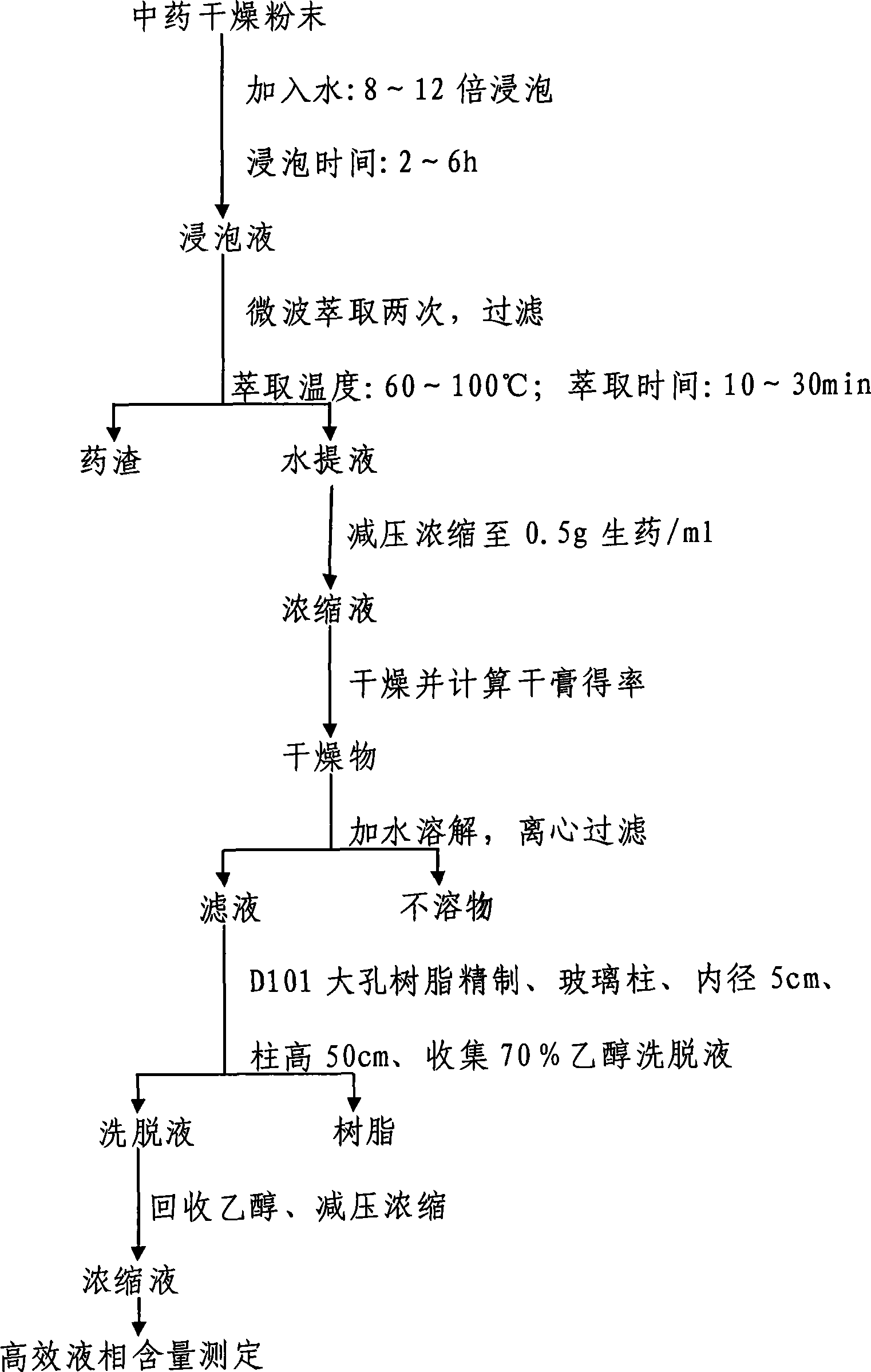

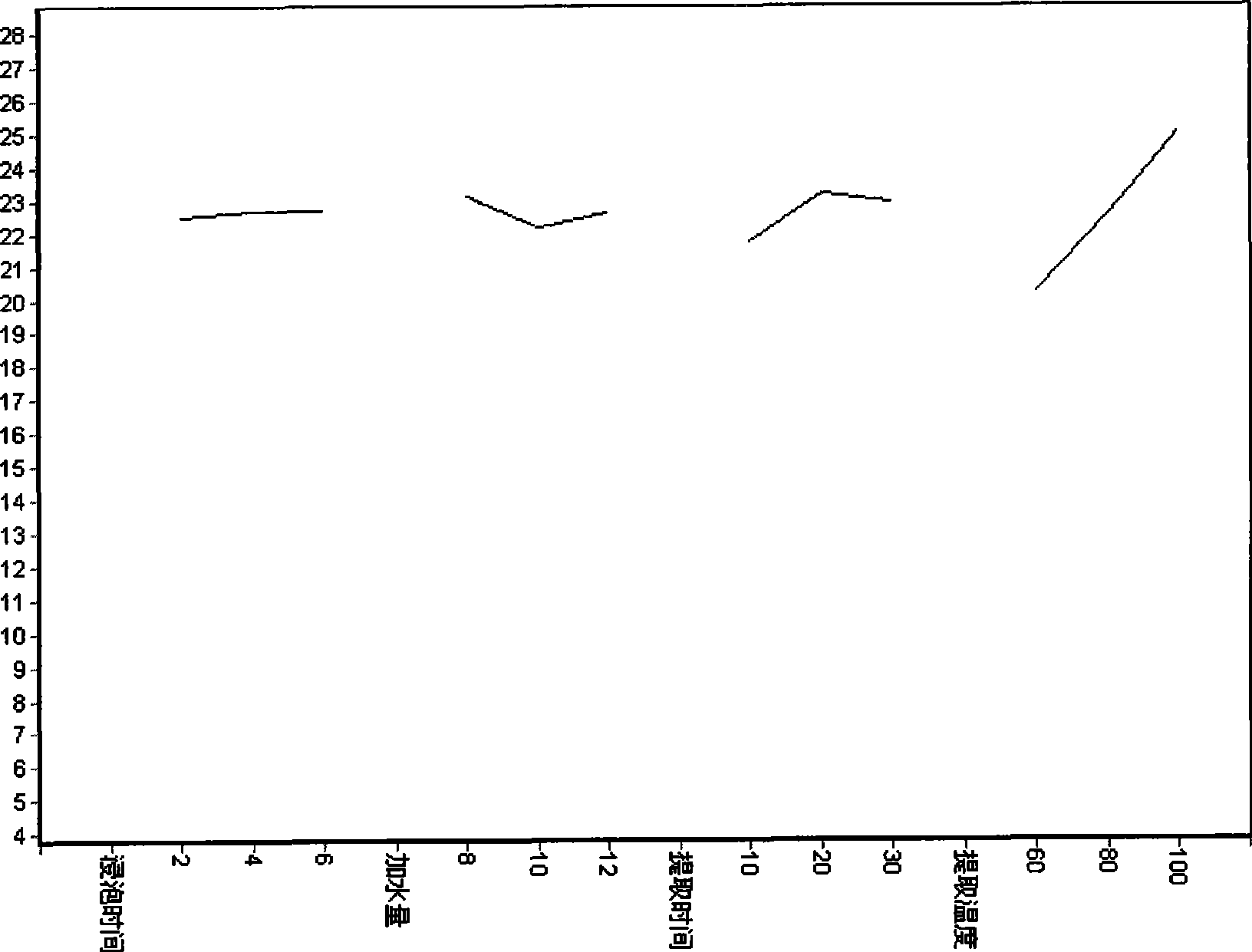

Technique for extracting mixed rhubarb and aconite

InactiveCN101439103AReduce extraction timeOvercome roughMetabolism disorderPlant ingredientsProduction lineMonkshoods

The invention relates to the blending extraction process of rhubarb and monkshood in compound Chinese medicine Xiaokening. The blending extraction process of the rhubarb and the monkshood comprises the following steps: mixed powder of the rhubarb and the monkshood is dipped in 6-15 times water for 2-8 hours; and then soak pollution is extracted twice under the assistance of microwave; after extraction liquid is centrifugal and filtered, double extractive supernatant fluids are combined and concentrated till the concentration of drug ingredients is 0.05-0.5g / ml, added with a macroporous resin column for adsorption; firstly, the macroporous resin column is washed with water, and then eluted with ethanol with gradient concentrations; ethanol eluent with 50-80 % of concentration is combined; ethanol is recycled; the blending extractive of the rhubarb and the monkshood is prepared by concentration. The blending extraction process organically combines the microwave assistance extraction process and the macromolecule absorption process and has the technology characteristics of high extraction rate and high purification precision. As the production is safe, reliable, and free from contamination, and the production line composition is simple, the investment is saved.

Owner:JIANGSU WANBANG BIOPHARMLS +1

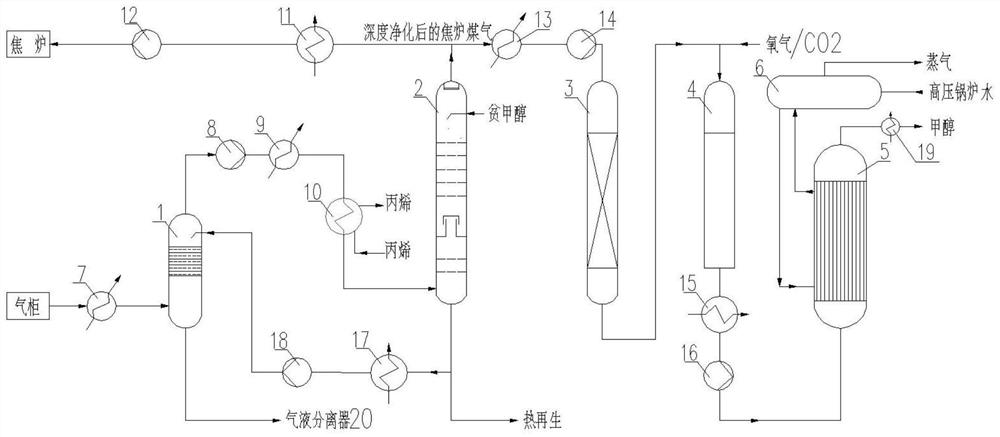

System and method for preparing methanol by deeply purifying coke oven gas

InactiveCN112920859AImprove cleanlinessSolve the blockageOrganic compound preparationHydroxy compound preparationBenzeneThermodynamics

The invention provides a system and method for preparing methanol by deeply purifying coke oven gas, and belongs to the field of coke oven gas purification. The pre-washing tower is arranged as a supergravity rotating device, so that the coke oven gas subjected to benzene removal can be subjected to primary impurity removal in the pre-washing tower through a supergravity rotating technology, harmful substances such as dust, benzene, tar, naphthalene, ammonia and sulfur in the coke oven gas are deeply removed, and the problem that the stable operation of a system is influenced after sulfur and ammonia in the coke oven gas exceed the standard is solved; and the problems that tar and naphthalene in the coke oven gas can cause blockage of a compression system, and the operation cost of fine desulfurization is increased due to abnormal coarse desulfurization are solved. Through pretreatment, the coke oven gas does not need to be desulfurized after returning to the coke oven, so that the investment of a flue gas desulfurization device and the generation of desulfurization waste liquid can be reduced. The hydrogen-carbon ratio of the synthesis gas is adjusted through a conversion technology to ensure that hydrogen and carbon in the coke oven gas can be utilized to the maximum extent, so that the yield of methanol can be increased.

Owner:SEDIN ENG

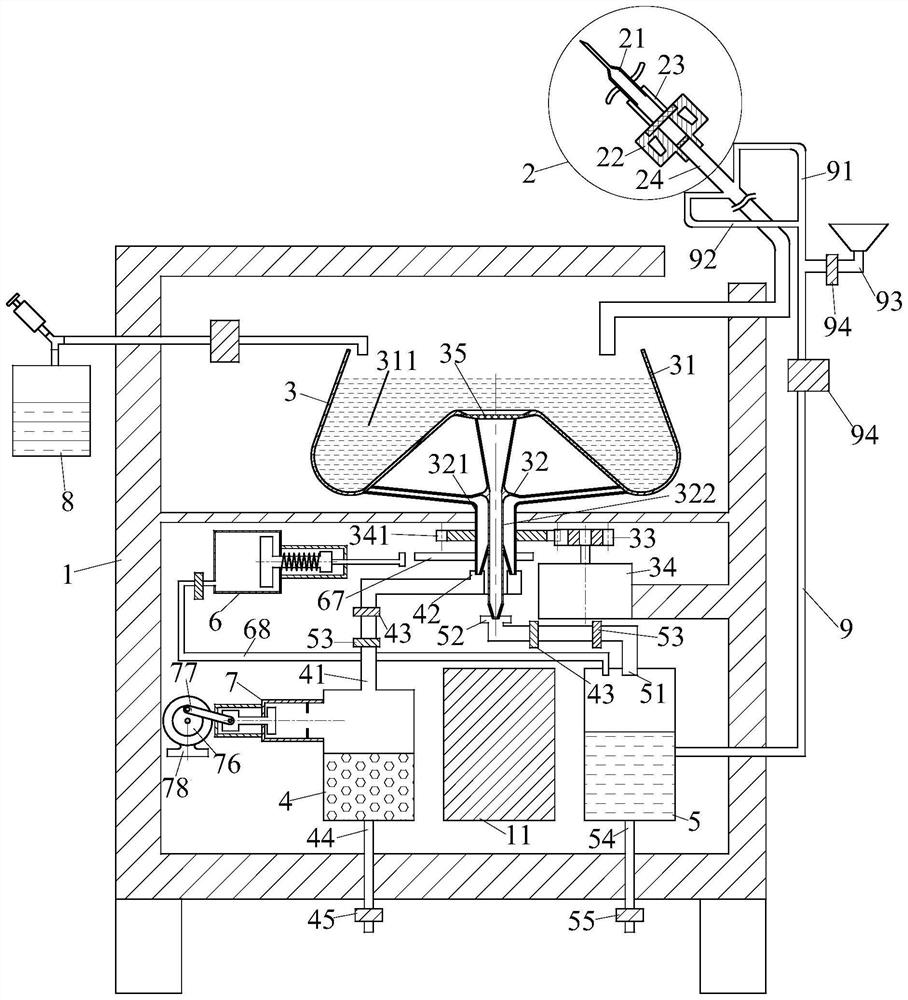

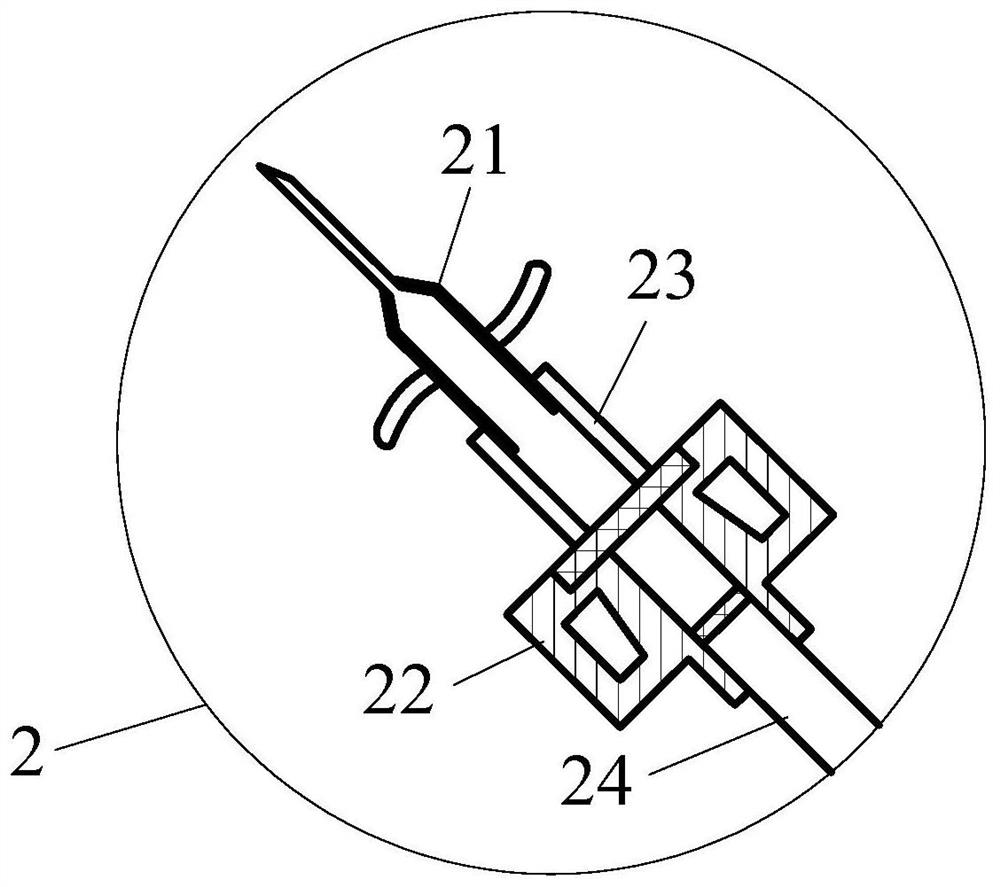

Medical hematopoietic stem cell collector

ActiveCN108359592AHigh purification precisionPrevent solidificationBioreactor/fermenter combinationsBiological substance pretreatmentsBlood Collection TubeEngineering

The invention belongs to the technical field of medical instruments and particularly relates to a medical hematopoietic stem cell collector which comprises a mounting body, a blood collection unit, astem cell separation unit, a stem cell collection tank, a plasma collection tank, a pressurization pump, a negative pressure pump, a heparin bottle, a plasma conveying pipe and an ice block storage tank; the blood collection unit is connected with the stem cell separation unit; the stem cell separation unit is connected with the stem cell collection tank and also is connected to a plasma separation tank; the pressurization pump is connected with the plasma collection tank; the negative pressure pump is connected with the stem cell collection tank; the heparin bottle is connected to the stem cell separation unit; one end of the plasma conveying pipe is connected with the blood collection unit; the other end of the plasma conveying pipe is connected with the plasma collection tank; and the plasma conveying pipe is also provided with a normal saline introduction pipe. The medical hematopoietic stem cell collector provided by the invention can improve the purification accuracy when stem cells are collected by keeping continuous working state.

Owner:东营凤起生物科技发展有限公司

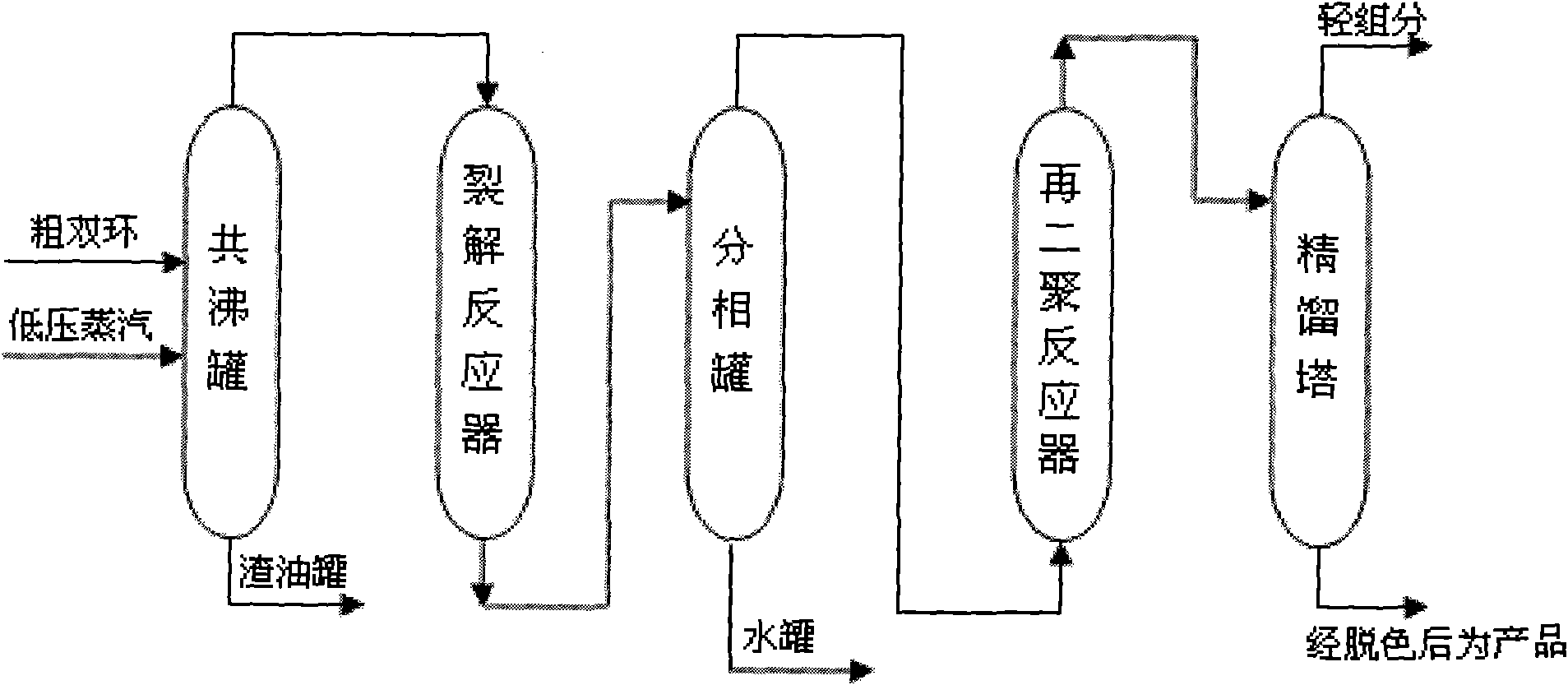

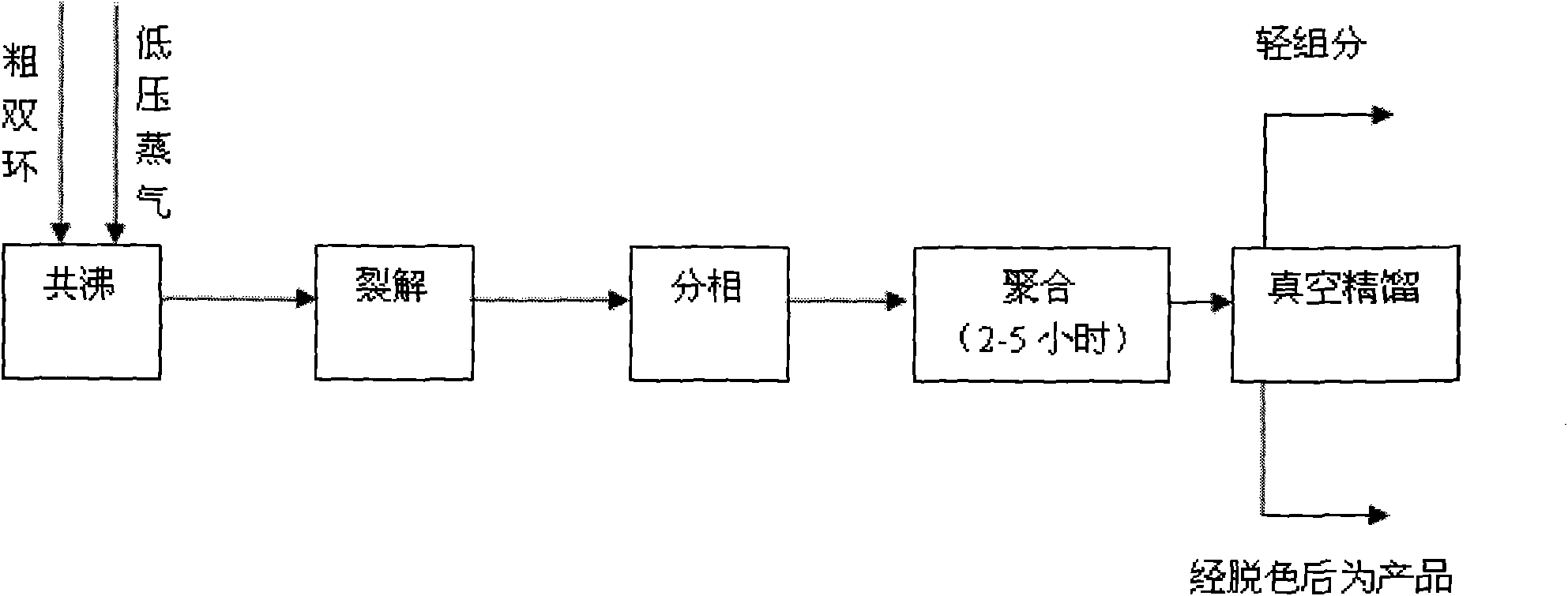

Preparation method of high purity dicyclopentadiene

ActiveCN101671224BHigh purification precisionEasy to industrializeDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionPetroleumRaw material

The invention belongs to the technical field of chemical engineering, and particularly discloses a preparation method of high purity dicyclopentadiene. The preparation method comprises the following steps: using a C5 fraction as a byproduct of ethane prepared through petroleum cracking as a raw material, cracking to prepare cyclopentadiene after gasification, and preparing the high purity dicyclopentadiene through polymeric rectification. The invention adopts a method of cracking-dimerization-rectification, and has the characteristics of low production cost, high purification precision and easy industrialization.

Owner:山东玉皇盛世化工股份有限公司

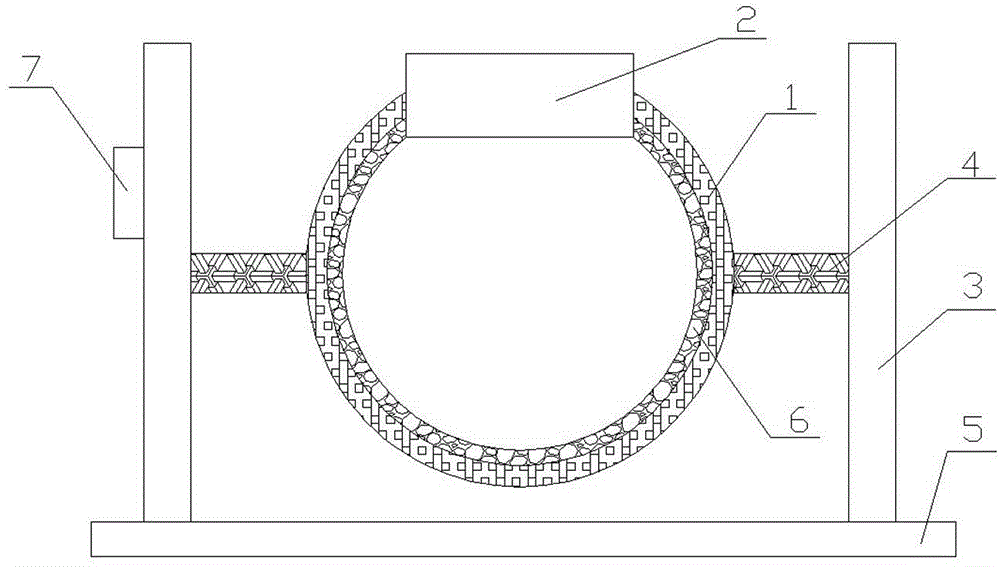

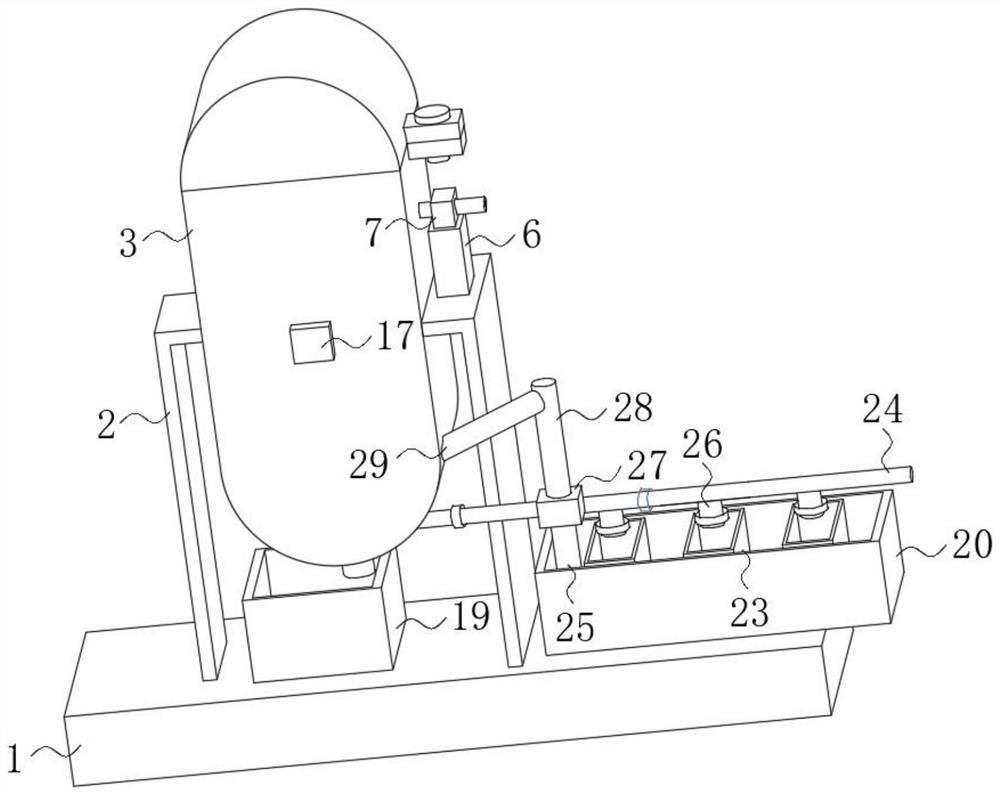

Spherical graphite purification furnace

The present invention discloses a spherical graphite purification furnace, which comprises a thermal insulation housing, a top cover, a bracket, a rotation shaft and a base, and is characterized in that the inner wall of the thermal insulation housing is provided with an infrared heating layer, the thermal insulation housing and the top cover are movably connected and are fixed by using a snapping buckle, the thermal insulation housing is spherical, both ends of the thermal insulation housing are connected to the rotation shaft, the outer side of the rotation shaft is connected to the bracket, and the bottom portion of the bracket is connected to the base. According to the present invention, with the rotation shaft, the spherical graphite purification furnace can rotate during the working, such that the heating area is uniform, and the purification precision is high; and with the control panel, the rotation speed of the rotation shaft and the temperature of the infrared heating layer of the spherical graphite purification furnace can be precisely controlled, such that the graphite purification precision is improved, and after completing the purification, the inclination angle of the spherical graphite purification furnace can be controlled so as to conveniently collect or pour out the purified graphite.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

A medical hematopoietic stem cell collection instrument

ActiveCN108359592BHigh purification precisionPrevent solidificationBioreactor/fermenter combinationsBiological substance pretreatmentsBlood collectionStem Cell Isolation

The invention belongs to the technical field of medical devices, specifically a medical hematopoietic stem cell collection instrument, including an installation body, a blood collection unit, a stem cell separation unit, a stem cell collection tank, a plasma collection tank, a pressurized pump, a negative pressure pump, a heparin bottle, The plasma conveying tube and the ice cube storage box, the blood collection unit is connected with the stem cell separation unit; the stem cell separation unit is connected with the stem cell collection tank; the stem cell separation unit is also connected with the plasma separation tank; the booster pump is connected with the plasma collection tank; The pressure pump is connected to the stem cell collection tank; the heparin bottle is connected to the stem cell separation unit; one end of the plasma delivery tube is connected to the blood collection unit, and the other end of the plasma delivery tube is connected to the plasma collection tank; the plasma delivery tube is also provided with a normal saline introduction tube; The invention can improve the purification precision of stem cell collection under the continuous working state.

Owner:东营凤起生物科技发展有限公司

A method for preparing high-purity aromatic pitch for high-end carbon materials

ActiveCN110272754BReduce energy consumptionSolve purification problemsWorking-up pitch/asphalt/bitumen by chemical meansDistillationActive agent

The invention belongs to the technical field of a preparation method for high-purity aromatic hydrocarbon pitch used for a high-end carbon material, and specifically relates to a preparation method for low-ash, low-sulfur and high-purity aromatic hydrocarbon pitch used for preparation of mesophase pitch. The preparation method comprises the following steps: dissolving aromatic hydrocarbon pitch into toluene, then adding a boron trifluoride-diethyl ether complex, carrying out stirring for layering at a normal temperature, separating out a high-density boron trifluoride-aromatic hydrocarbon pitch complex obtained at a bottom part, then adding the toluene and pyridine, further carrying out stirring for layering, removing a majority of the boron trifluoride, adding ammonia water and low-molecular alcohol or a surfactant, carrying out extraction for a plurality of times, and carrying out distillation so as to obtain the high-purity aromatic hydrocarbon pitch. The preparation method provided by invention is performed at a normal temperature, has low energy consumption and good purification and separation effects, is simple in equipment and low in investment and cost, and avoids the disadvantages of a conventional filtration and hydrogenation process.

Owner:湖南东映碳材料科技股份有限公司

High energy beam polysilicon purifying device

The invention discloses a device for purifying polysilicon by using a high energy beam, comprising a vacuum chamber, a vacuum electromagnetic induction smelting unit, an electron beam smelting unit, aplasma smelting unit and a directional solidification unit. The vacuum electromagnetic induction smelting unit is arranged on a concave surface of the vacuum chamber; an A electron gun of the electron beam smelting unit is arranged on a left inclined plane of the vacuum chamber and a B electron gun is arranged on a right inclined plane of the vacuum chamber; an A plasma gun of the plasma smeltingunit is arranged on a left shell body of the vacuum chamber and a B plasma gun is arranged on a right shell body of the vacuum chamber; a connecting base of the directional solidification unit is arranged on a separator of the vacuum chamber; the invention aims at providing a device for purifying the polysilicon by using the high energy beam which integrates four technologies of the vacuum electromagnetic induction smelting, the plasma smelting, the electron beam smelting and the directional solidification; the purifying device carries out vacuum electromagnetic induction smelting, plasma smelting, electron beam smelting and directional solidification sequentially for silicon metal of 99.9 percent to obtain the polysilicon with a purity of 99.9999 percent which is used for producing solarbatteries. The invention solves the defects of large equipment input, high cost, large energy consumption and serious environmental pollution in the prior chemical methods for producing solar grade silicon.

Owner:BEIHANG UNIV

Pressure-variation adsorption separation recovering method for mixd gas containing chloroethylene and acetylene

InactiveCN100358849CAdjust or increase concentrationHigh purification precisionDispersed particle separationHalogenated hydrocarbon preparationRecovery methodSorbent

This invention relates to variable voltage absorbing separating recovery method of vinyl chloride and acetylene mixed gas. Each absorbing tower through the variable absorbing cycle process of absorbing, inverse disperse, evacuation and final boosting procedures is done. The mixed gas is processed at least two variable voltage absorbing unit, discharged gas processed by front unit in turn entering next nearby absorbing unit to get vinyl chloride and acetylene product gas. at least two absorbing tower are contained in each variable voltage absorbing unit, absorbing agent in the first tower at least contains alumina, at least one of average aperture 1-3mm silica gel or molecular sieve is contained in last variable voltage absorbing unit. This method is propitious to process mixed gas that contain more C2H3Cl and C2H2, it can make C2H3Cl and C2H2 concentrate 2-200 times, and make C2H3Cl and C2H2 be separately separated, recovered and used by the mixed gas. C2H3Cl and C2H2 in detergent effluent gas can reach environmental protection request.

Owner:四川开元科技有限责任公司

After-treatment purification method of vinylcarbazole

InactiveCN104356049ATo achieve the purpose of purificationHigh purification precisionOrganic chemistryChromatographic separationPurification methods

The invention provides an after-treatment purification method of vinylcarbazole. The method is high in purification precision and convenient to operate. Column chromatographic separation is performed on a vinylcarbazole crude product containing 5-50 wt% of raw carbazole material with two or more chromatographic columns, and a vinylcarbazole product is collected; an adopted mobile phase comprises two of petroleum ether, cyclohexane, benzene, diethyl ether, chloroform, ethyl acetate, n-butyl alcohol, acetone, ethyl alcohol and methyl alcohol and further comprises triethylamine; a stationary phase of each chromatographic column comprises one or more of silica gel, aluminium oxide, activated carbon, magnesium silicate and polyamide. According to the after-treatment purification method of the vinylcarbazole, the difference in polarities of various organic solvents is used, and the purification purpose is achieved with a column chromatography method with the multiple columns connected in series; the method is high in purification precision, convenient to operate and low in cost.

Owner:HUBEI HECHANG NEW MATERIAL TECH

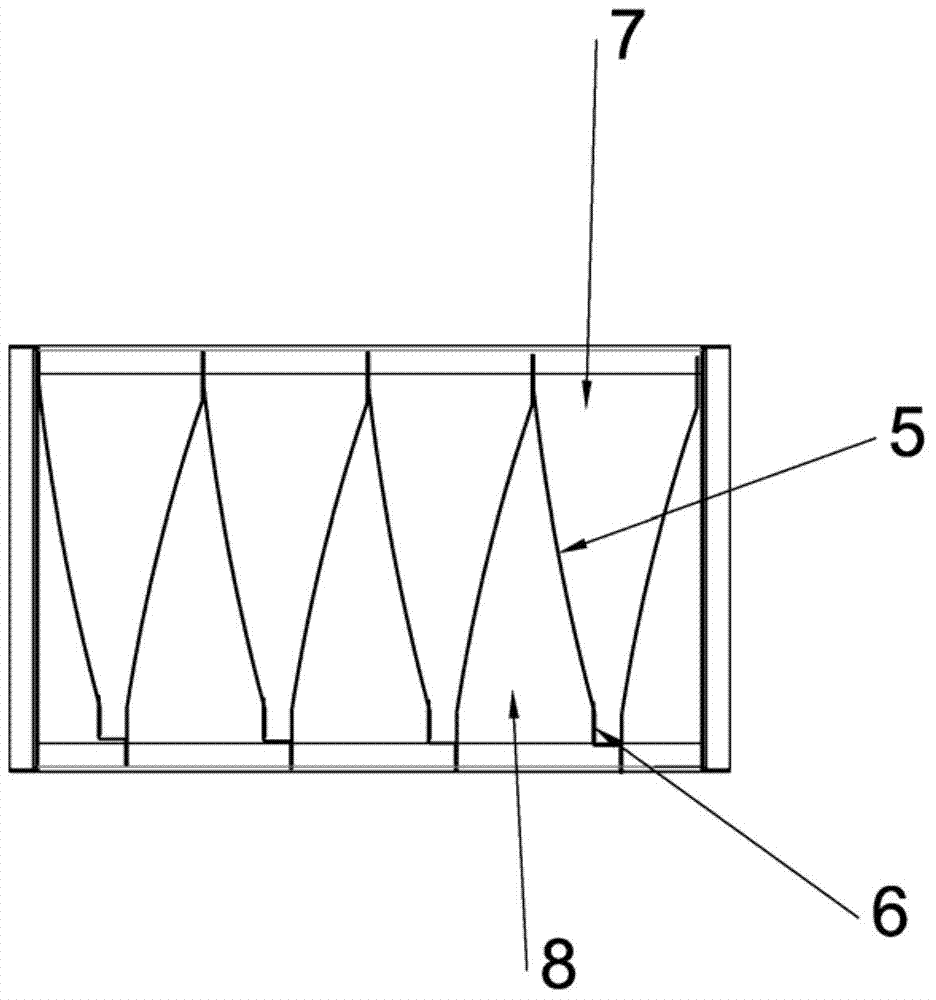

Centrifugal type preposed filtering device

ActiveCN103877792AImprove filtration efficiencyLighten the burden of filtrationDispersed particle separationFree formEngineering

The invention discloses a centrifugal type preposed filtering device. The filtering device comprises a top plate, and a bottom plate and side plates which are fixedly connected with the top plate. The filtering device also comprises a filtering unit, wherein the filtering unit comprises blade hole plates, blind plates and Z-shaped groove plates; one side edge of each blade hole plate coincides with one edge of the corresponding blind plate, the lower end part of the coinciding edge of the blind plate is connected with one Z-shaped groove plate through a rivet, and the other side edge of the blade hole plate is connected with another blind plate adjacent to the blind plate; the blind plates and the blade hole plates are sequentially connected to form an M-shaped structure. Since the filtering device is made from galvanized plates or stainless steel plates and the distribution of filtering holes conforms to the gas flowing principle, the filtering device has the advantages of being high in purification efficiency, free form replacement of filtering elements, low in operation resistance and convenient to clean and maintain.

Owner:MEGAUNITY ENVIRONMENTAL SOLUTIONS CO LTD

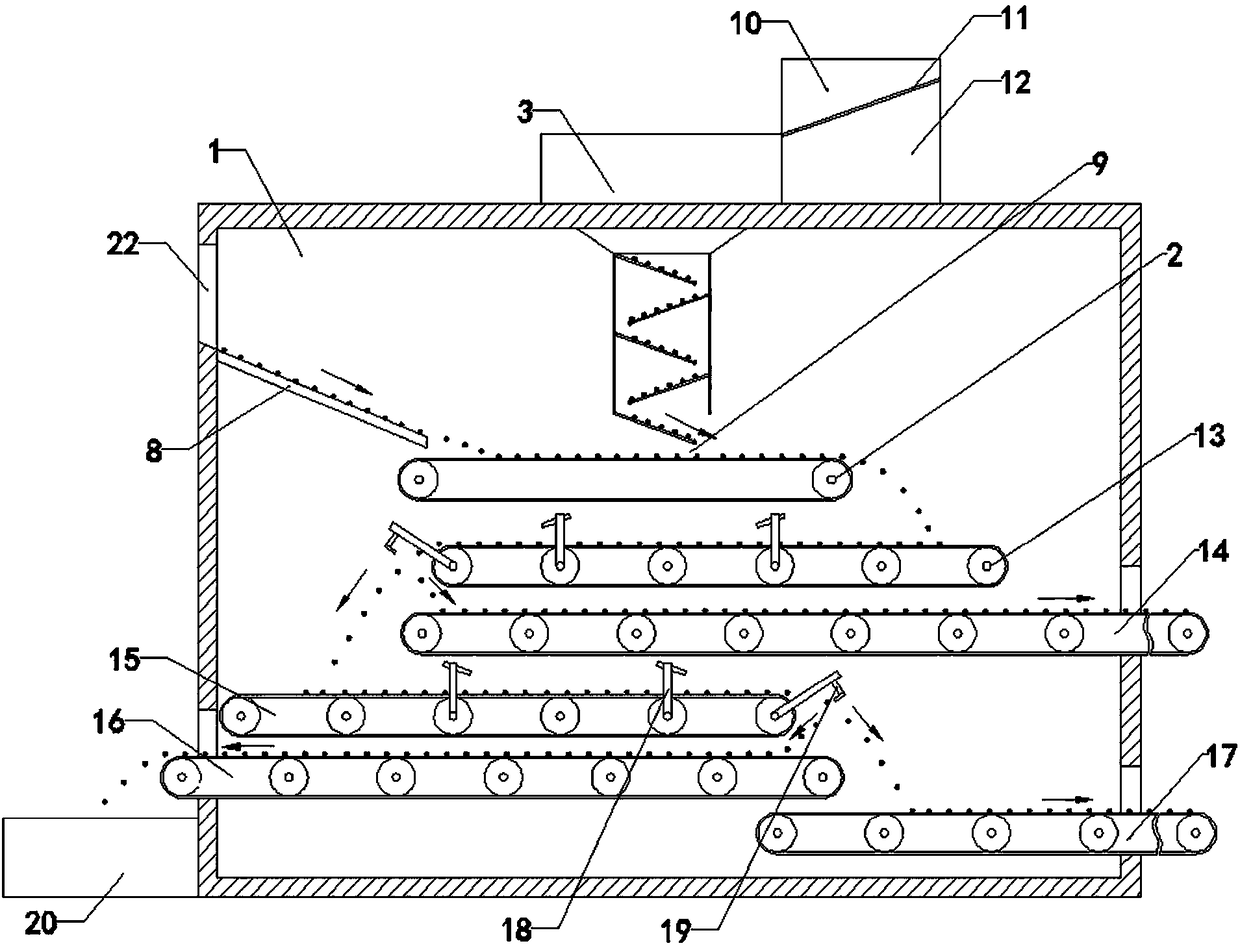

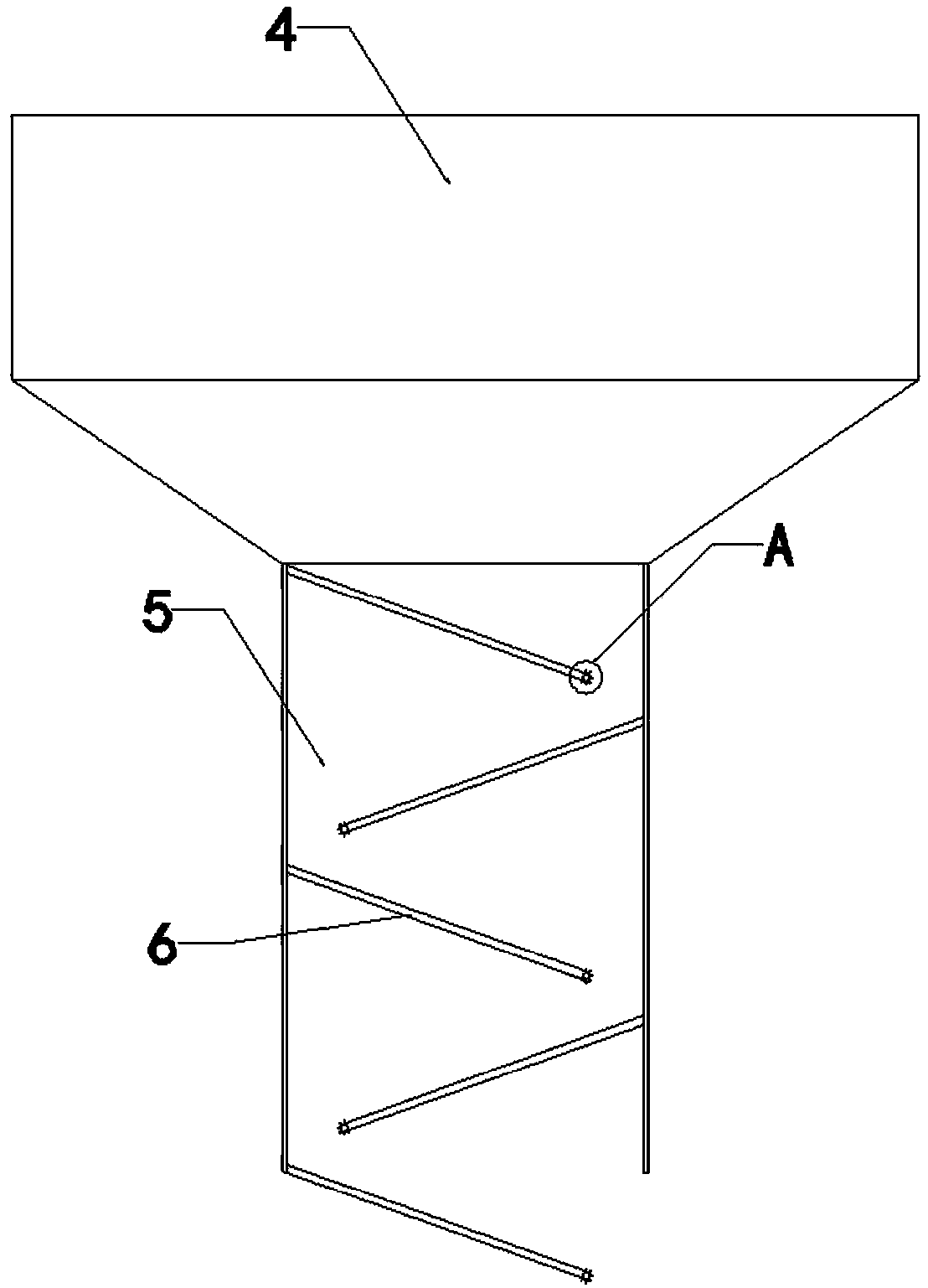

Potassium feldspar tailing purifying device and purifying process based on same

PendingCN108380526AAvoid the problem of uneven distribution or even stackingImprove detection accuracySortingBiochemical engineeringPotassium

The invention relates to the technical field of potassium feldspar machining, and discloses a potassium feldspar tailing purifying device and a purifying process based on the potassium feldspar tailing purifying device. The potassium feldspar tailing purifying device comprises a sorting machine body, and a distributor is arranged in the sorting machine body. A feeding device is arranged on the upper portion of the distributor. The feeding device comprises a feeding tank and a feeding pipe, and a plurality of guide plates are arranged in the feeding pipe. A plurality of gears capable of rotating are arranged at the ends of the guide plates side by side. A feeding plate corresponding to the distributor is arranged on the inner wall of the sorting machine body, a clearance is arranged betweenthe lowest guide plate and the upper surface of the distributor, and the height of the clearance ranges from 10 mm to 20 mm. According to the potassium feldspar tailing purifying device, raw materials can be divided and arranged on the distributor side by side, and therefore the problem that the raw materials are uneven in distribution and are even stacked together is avoided, and the detection accuracy can be improved. When the lower portions of the gears are clamped, the raw materials are in contact with the upper portions or sides of the gears, the gears can be driven to rotate, and therefore the raw materials clamped on the lower portions of the gears are moved, and the problem of material clamping is solved. According to the potassium feldspar tailing purifying device and the purifying process based on the potassium feldspar tailing purifying device, the detection efficiency is improved, and the detection accuracy is improved.

Owner:乐山市南联环资科技有限责任公司

Preparation method of maleic anhydride modified epoxy phosphate EMP

The invention provides a preparation method of maleic anhydride modified epoxy phosphate EMP with high purification precision and convenience in operation. The preparation method comprises the following steps: reacting n-butyl alcohol and MA (maleic anhydride) to prepare a maleic anhydride monoester: putting measured n-butyl alcohol, MA and tetrabutylammonium bromide into a four-neck bottle with a stirrer and a temperature gauge, slowly heating to 60-80 DEG C, and performing heat-preservation reaction for 3 hours in the temperature range; 2, preparing maleic anhydride modified epoxy resin: adding measured E-51 epoxy resin into the monoester, heating to 110-130 DEG C, performing heat-preservation reaction for about 3 hours, sampling and measuring an acid value, stopping reaction until the acid value is less than 5mg KOH / g, and cooling to less than 80 DEG C for later use; 3, preparing EMP: adding measured phosphoric acid into the maleic anhydride modified epoxy resin, reacting for 3 hours at 60-80 DEG C, then adding measured water, reacting for 2 hours at 80-100 DEG C, and hydrolyzing phosphate diester or phosphotriester in EMP into phosphate monoester. The preparation method of maleic anhydride modified epoxy phosphate EMP provided by the invention is high in purification precision, is convenient to manufacture and operate, and is low in cost.

Owner:HUBEI JIACAI NEW MATERIALS

Water quality purification tank system

InactiveCN104045175AHigh purification precisionSimple structureMultistage water/sewage treatmentWater/sewage treatment by sorptionWater qualityWater supply

The invention relates to a water quality purification tank system, comprising a water inlet, a water outlet, a first purification tank, a second purification tank and a third purification tank, wherein the interior of the first purification tank is provided with at least two layers of first filter screen, one side of the lower end of the first purification tank is provided with an air inlet, water supply pipes are arranged among the first purification tank, the second purification tank and the third purification tank, water outlet ends of the water supply pipes are located at the upper ends of tank bodies, water inlet ends of the water supply pipes are located at the lower ends of the tank bodies, the water supply pipes are provided with a first-grade detection gauge and a second-grade detection gauge, the interior of the second purification tank is provided with a plurality of adsorption balls with a certain diameter, the interior of the third purification tank is provided with at least two layers of second filter screen, and the water outlet is positioned at the upper end of the third purification tank. The water quality purification tank system has a simple structure and is reasonably designed; through arrangement of the first purification tank, the second purification tank and the third purification tank, multistage multistep purification and high purification precision of water can be realized.

Owner:协多利洁净系统(常州)有限公司

Surfactant P-1000 formula

InactiveCN104190315AHigh purification precisionEasy to operateTransportation and packagingMixingPhosphoric acidSURFACTANT BLEND

The invention provides a surfactant P-1000 formula, and a surfactant P-1000 is high in purification precision and convenient to operate. The surfactant P-1000 comprises 1000 parts of PEG1000, 196 parts of MA, 800 parts of E-51, 196 parts of phosphoric acid, 12 parts of tetrabutylammonium bromide and 60 parts of water. The surfactant P-1000 with the formula disclosed by the invention is high in purification precision, convenient to manufacture and operate and low in cost.

Owner:HUBEI JIACAI NEW MATERIALS

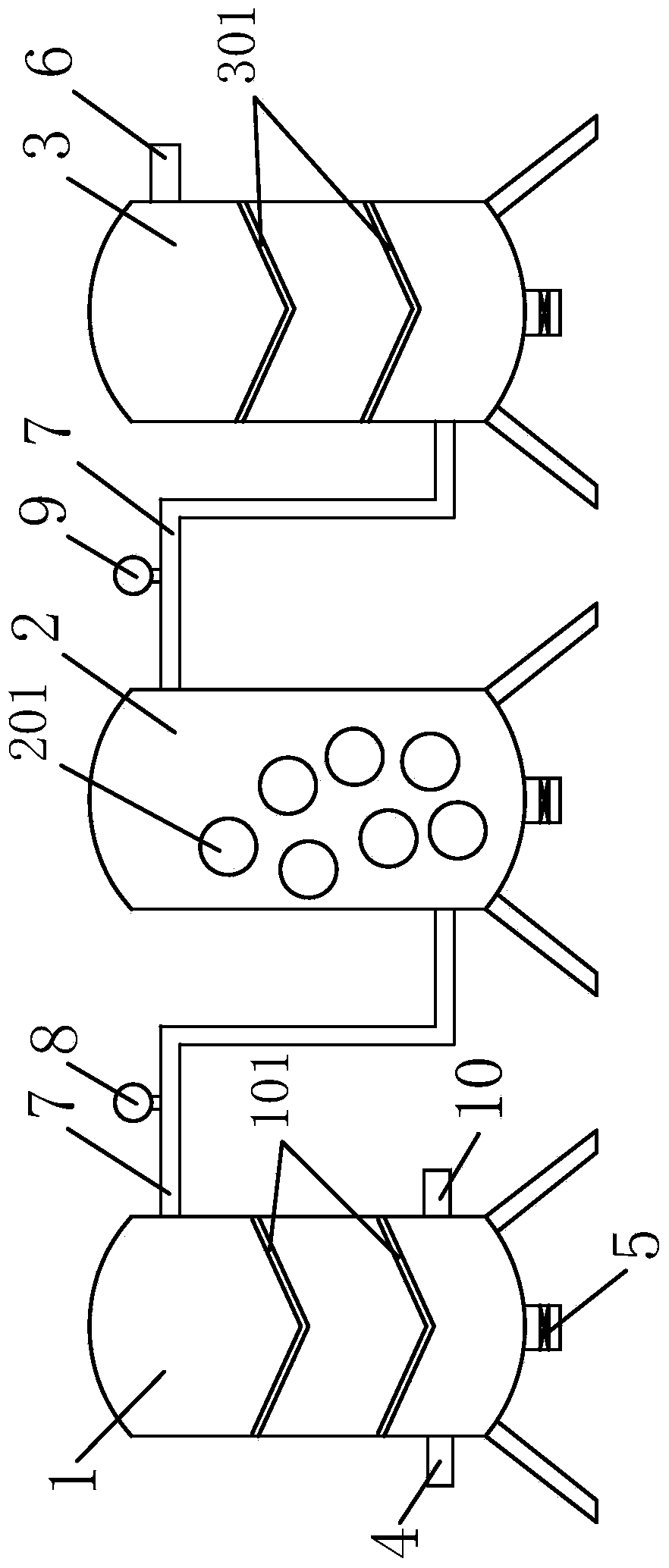

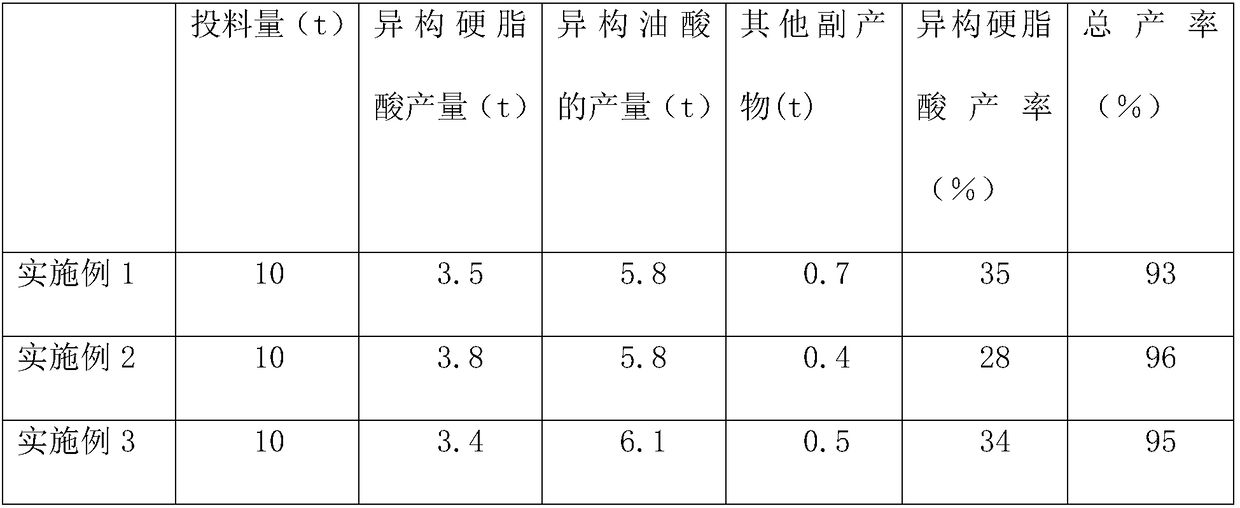

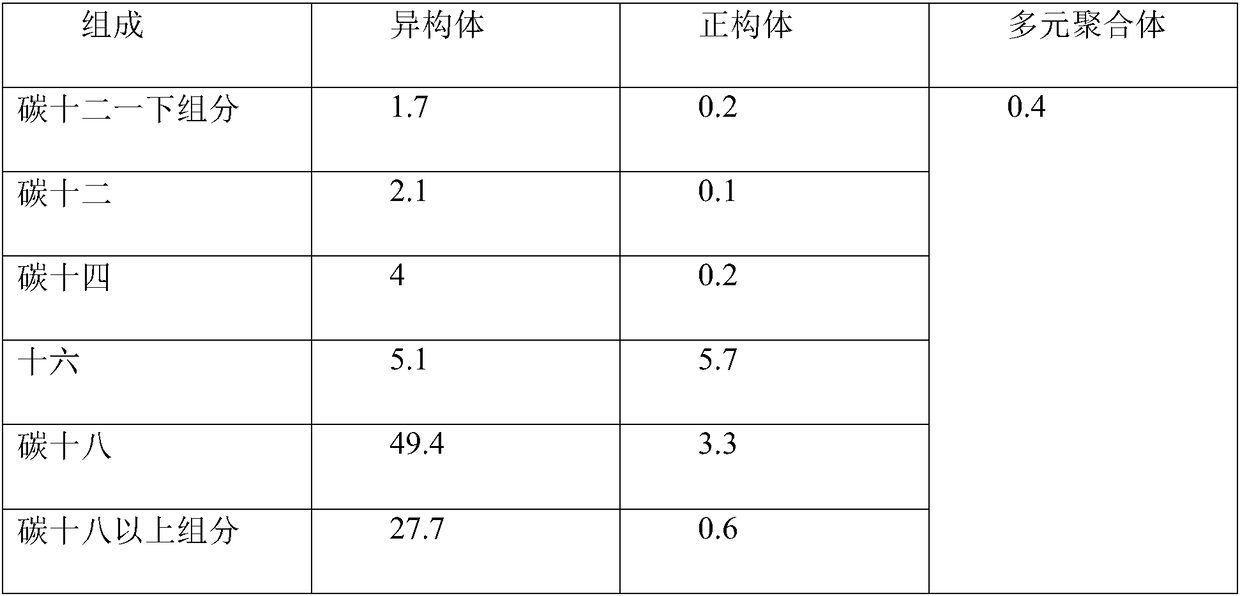

Method for preparing isomeric stearic acid by means of freezing crystallization and fractionation

InactiveCN108299188AReduce generationReduce the numberCarboxylic compound separation/purificationFractionationCarboxylic acid

The invention belongs to the technical field of preparation of isomeric stearic acid, and in particular relates to a method for preparing isomeric stearic acid by means of freezing crystallization andfractionation. According to the low temperature performance of the isomeric stearic acid, aliphatic carboxylic acid subjected to a polymer reaction is put into a low-temperature cold storage, so thatcrystals of the isomeric stearic acid can be obtained; in separation and purification processes, heating steps are fewer, so that less hot steam is produced in the purification process; compared withthe existing separation and purification steps, the method is more environmentally friendly; furthermore, the method is less in number of used equipment and simple to operate, thus being both lower in economic cost and labor cost.

Owner:杨友红

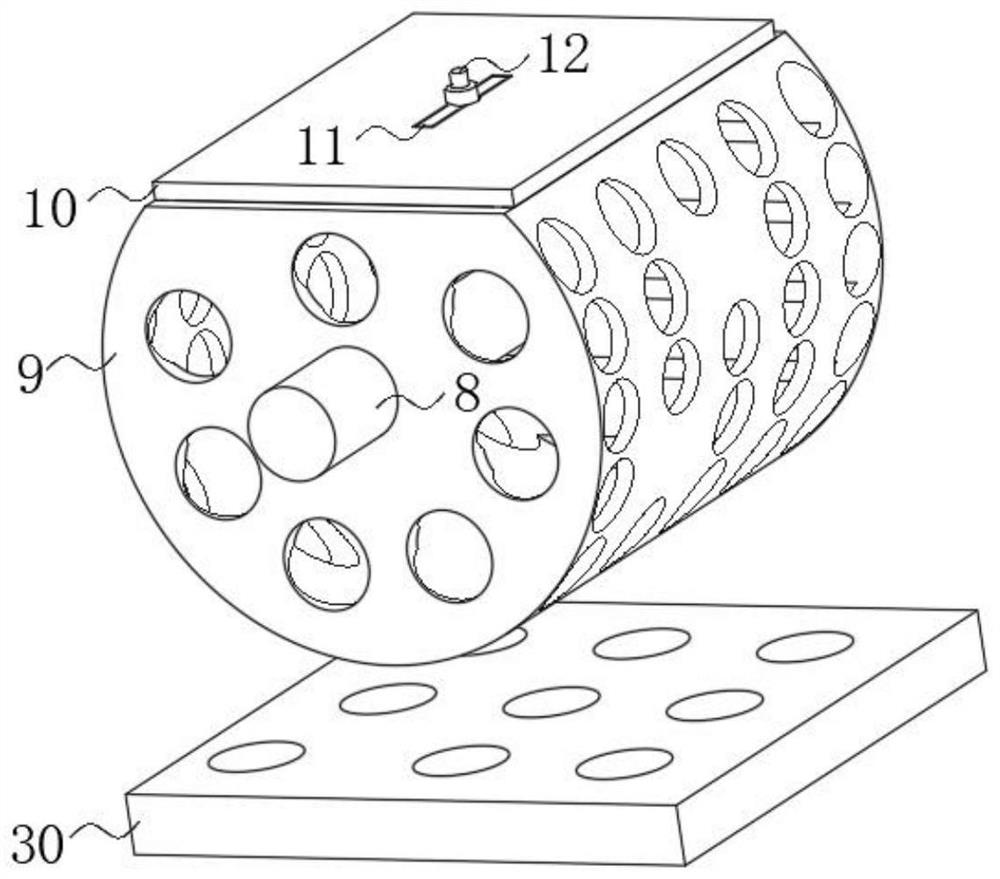

Vacuum purification equipment for recycling non-ferrous metals from electronic wastes

ActiveCN113549770AEfficient separationHigh purification precisionHollow article cleaningProcess efficiency improvementMolten stateElectric machine

The invention discloses vacuum purification equipment for recycling non-ferrous metals from electronic wastes. The vacuum purification equipment comprises a placement seat, a shell is fixedly mounted on the placement seat through fixing frames, a vacuum box is fixedly mounted in the shell through two fixing rings, and a vacuumizing structure is mounted between the vacuum box and one of the fixing frames; a rotating shaft is rotatably installed in the vacuum box, a motor is fixedly installed on the outer wall of the shell, and one end of the rotating shaft penetrates through the vacuum box and the shell to be fixedly installed at the driving end of the motor. The vacuum purification equipment has the advantages that a one-way discharge pipe I, a material receiving seat I, a material receiving seat II, a one-way discharge pipe II and a discharging pipe are matched for use, so that impurities and non-ferrous metals with different melting temperatures can be effectively separated, and the purification precision is improved; and meanwhile, a rotatable cover cage is arranged, so that materials which are not melted in the melting process can be in more sufficient contact with materials in a molten state, and the overall melting speed is increased.

Owner:烟台金钪稀贵金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com