Potassium feldspar tailing purifying device and purifying process based on same

A technology of potassium feldspar and tailings, which is applied in the field of purification of potassium feldspar tailings and purification technology, can solve the problems of affecting the detection results, low working intensity of the lens, and error-prone detection, so as to avoid uneven distribution and solve the problem of material jam , Improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

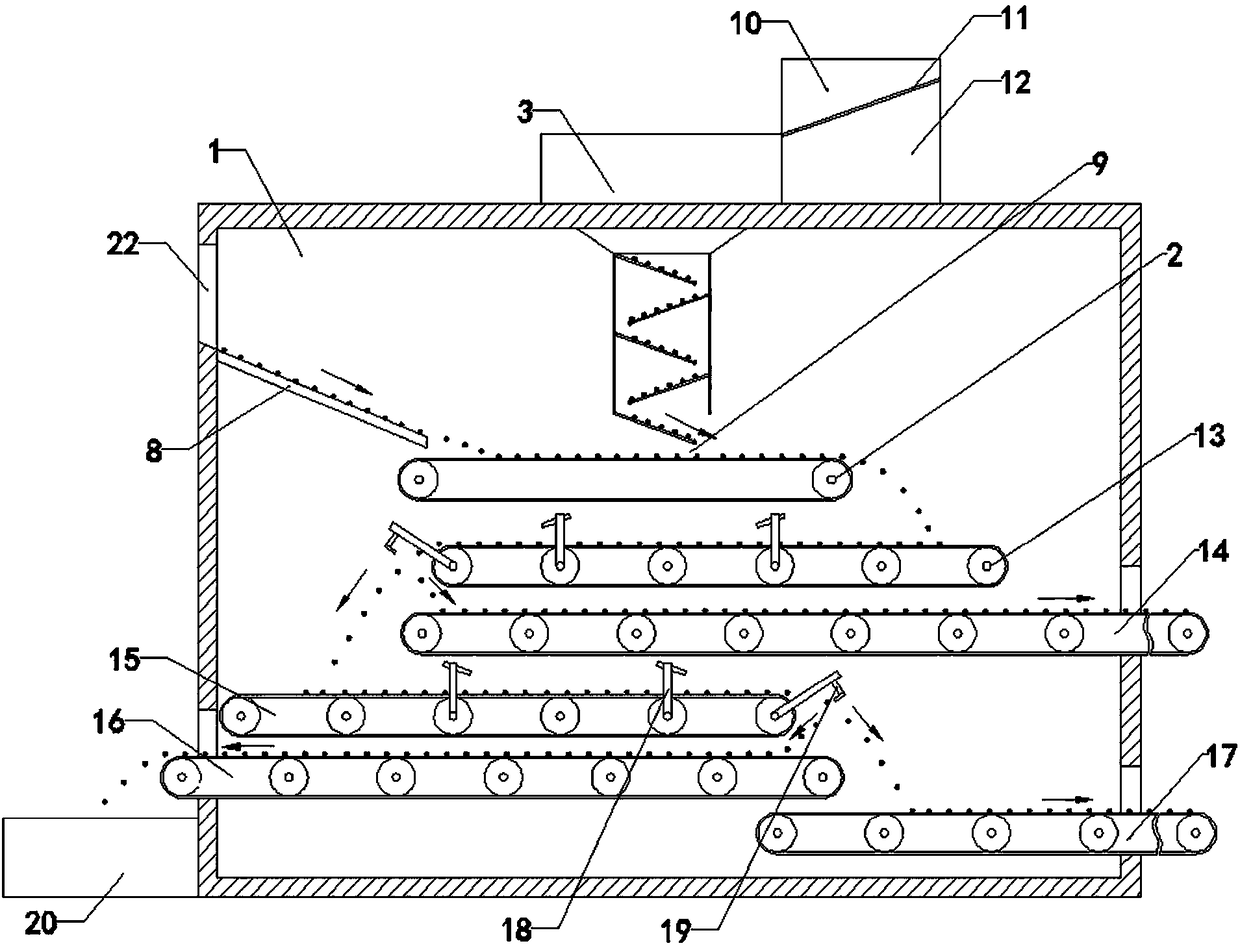

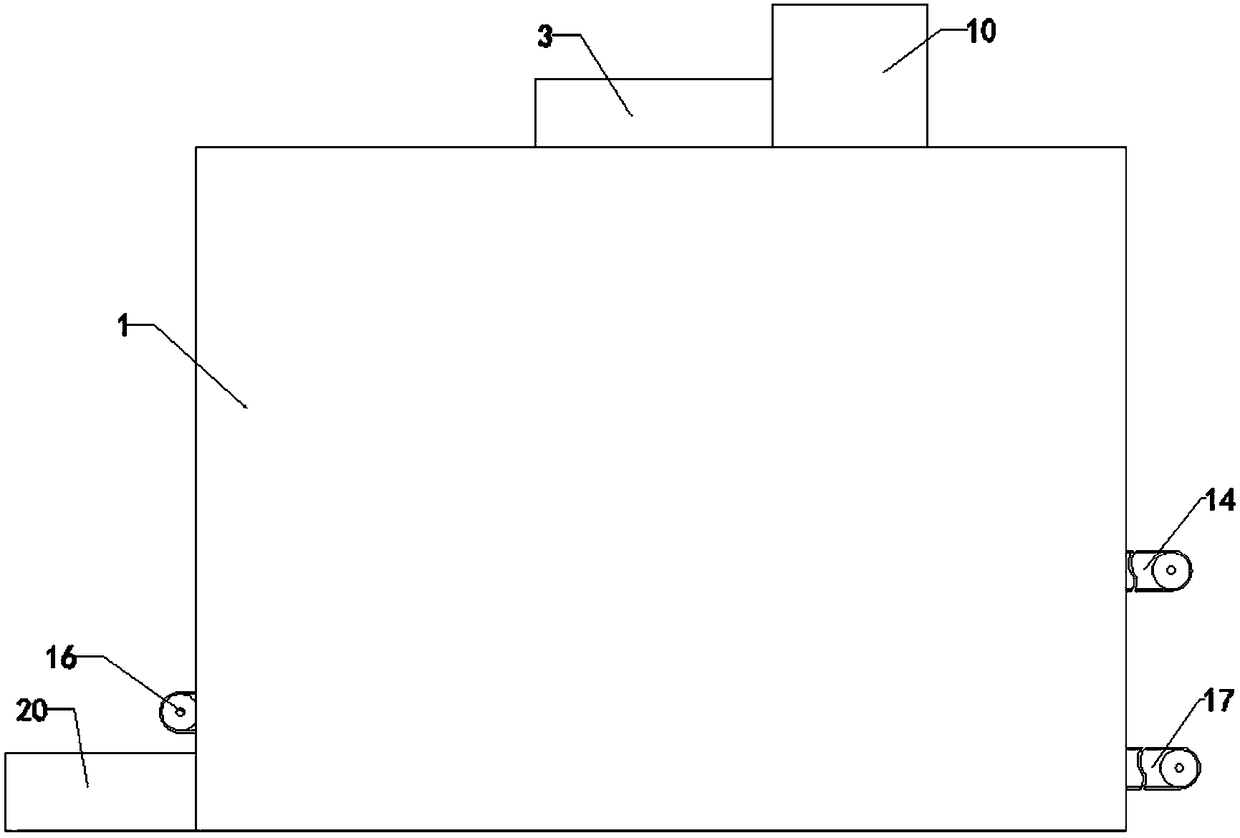

[0068] A potassium feldspar tailings purification device, comprising a separator main body 1, a distributor 2 is horizontally arranged inside the separator main body 1, and a feeding device 3 is arranged on the upper part of the distributor 2;

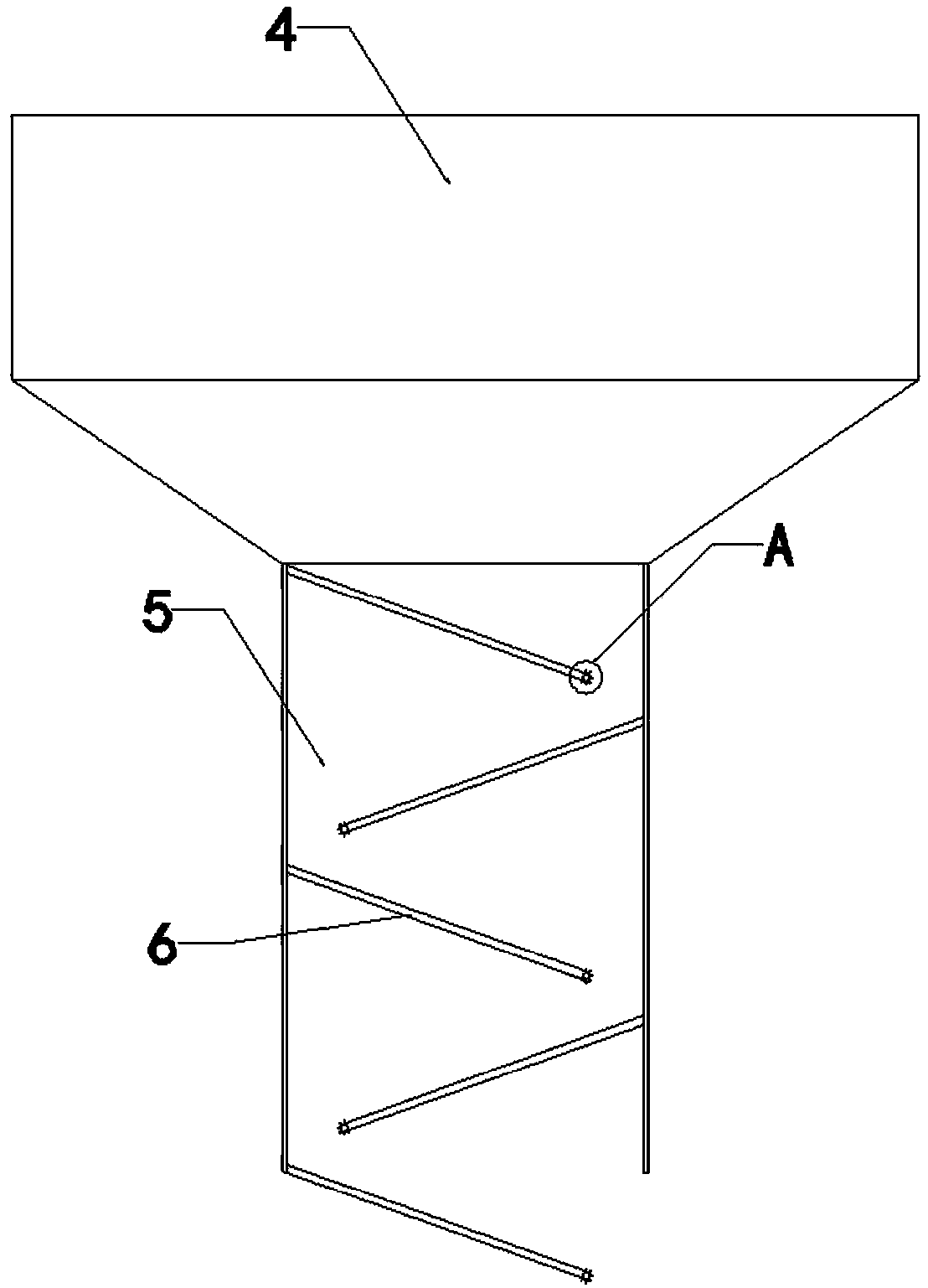

[0069] The feeding device 3 includes an upper feed tank 4 and a feed pipe 5 arranged at the bottom of the feed tank 4. The feed pipe 5 is internally provided with a plurality of downwardly inclined material guide plates 6, and a plurality of guide plates The material plates 6 are staggered left and right, and the ends of the material guide plate 6 are arranged side by side with a plurality of rotatable gears 7, the gears 7 protrude from the material guide plate 6 and the axis direction of the gear 7 is perpendicular to the length direction of the feed pipe 5;

[0070] One side of the inner wall of the main body of the sorting machine 1 is inclined downward to be provided with a feeding plate 8 corresponding to the distributor 2, and the...

Embodiment 2

[0072] This embodiment is further optimized based on Embodiment 1. The top of the sorter main body 1 is located on the side of the feeding trough 4 and is provided with a vibrating screen 10. The trough 12, the screen 11 is arranged inclined downward, and the lower end of the screen 11 is connected with the upper part of the feed trough 4 .

[0073] Due to the limited strength of the lens detection of the main body 1 of the sorting machine, if the detected raw material particles are small, if too many small raw materials are mixed in the raw materials during detection, the raw materials passing through the lens per unit time will increase, thereby increasing or even exceeding The working intensity of the lens affects the detection accuracy; before purification, the present invention screens the too small raw materials through the vibrating sieve 10, so that the working intensity of the lens will not be exceeded during the purification process, and the purification accuracy is i...

Embodiment 3

[0075] This embodiment is further optimized based on Embodiment 2. The aperture of the sieve 11 is 4 mm, which can screen raw materials with an aperture smaller than 4 mm, so that the working strength of the lens will not be too large or too small, so that the detection accuracy can be satisfied. , to maximize the detection speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com