Intelligent treatment equipment of oil containing sewage

A technology for treating equipment and oily sewage, which is applied in the directions of grease/oily substance/floating matter removal device, liquid separation, separation method, etc. The effect of high purification accuracy and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

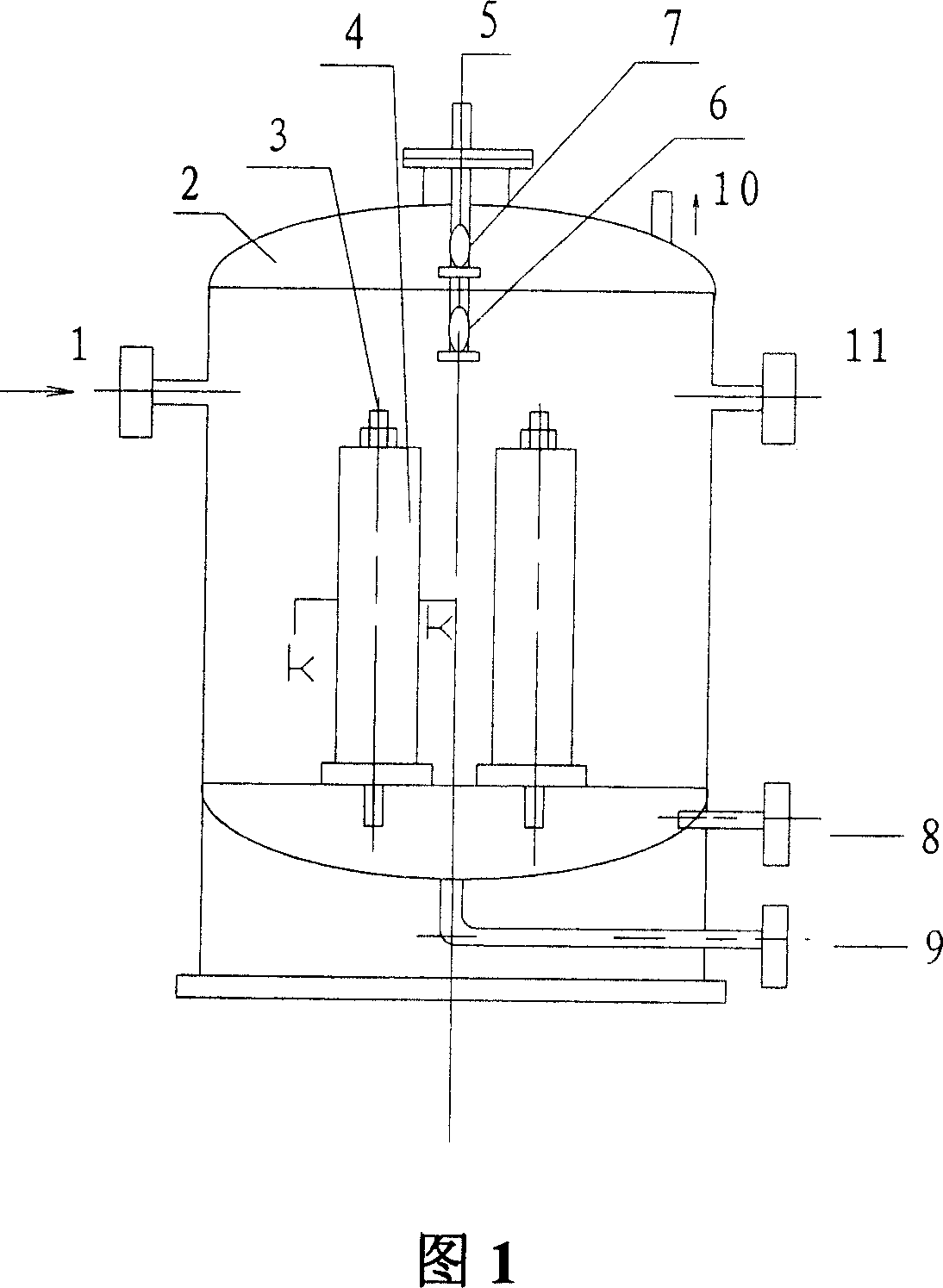

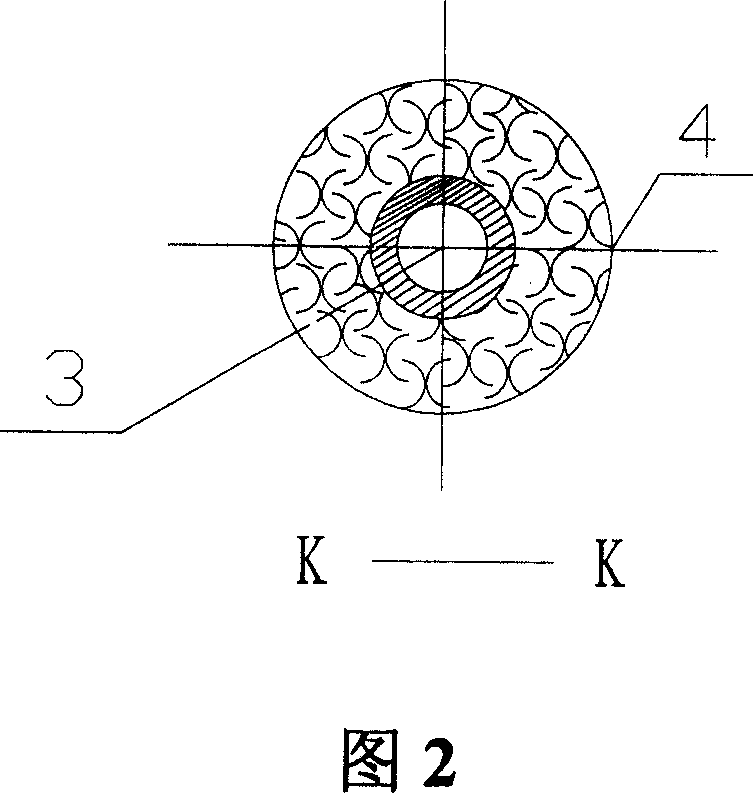

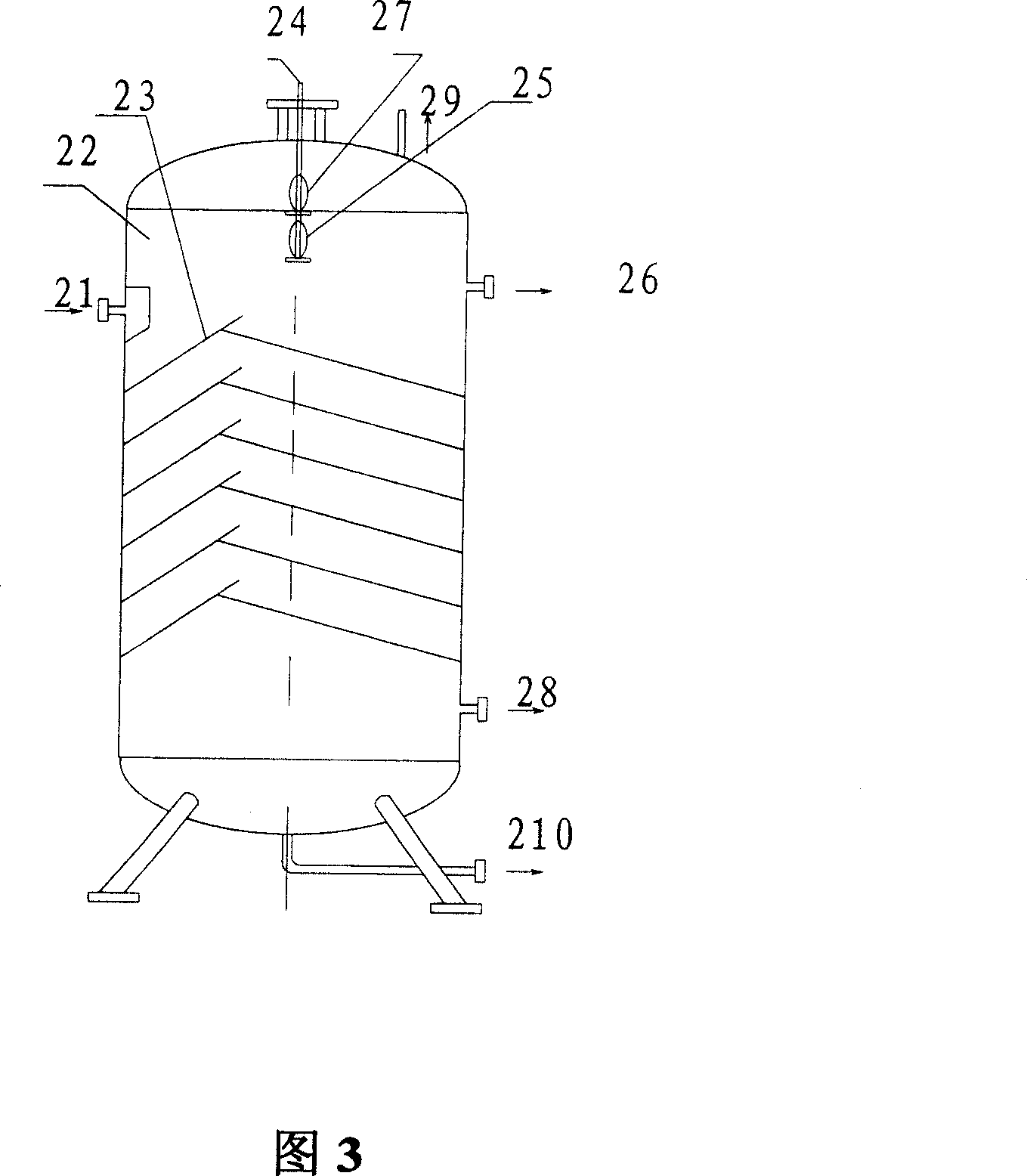

[0012] The intelligent oily sewage treatment equipment of the present invention includes a physical demulsification atomizer 2 and an oil-water separator 22 . Please refer to Fig. 1, the physical demulsification atomizer 2 is in the shape of a cylinder, and its upper part is provided with an oily sewage water inlet pipe 1, and a raw oily sewage enters the above-mentioned demulsification atomizer from the above sewage water inlet pipe 1 2. The upper part is also provided with an oil discharge pipe 11, which can discharge the purified oil from the upper part. The upper part is also provided with a sensor 5. The sensor 5 is provided with an interface ball 6 and a liquid level ball 7. The interface ball 6 can control The above-mentioned oil discharge pipe 11 discharges oil, and the top of the above-mentioned demulsification atomizer 2 has an exhaust pipe 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com