New technology and system for preparing high-purity carbon monoxide by temperature control transformation

A carbon monoxide and temperature control conversion technology, which is applied in the field of new processes and systems for preparing high-purity carbon monoxide, can solve problems such as high cost, and achieve the effects of low cost, simple process and high purification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

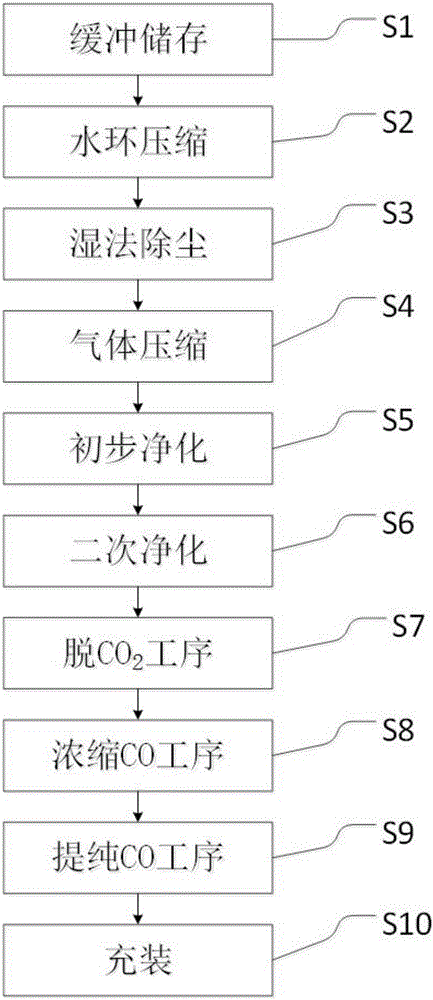

[0032] like figure 1 Shown, a kind of new technology that utilizes temperature-controlled transformation to prepare high-purity carbon monoxide comprises the following steps:

[0033] S1. Buffer storage: Send the tail gas of the calcium carbide furnace into the carbon monoxide gas holder for buffering, mixing and storage;

[0034] S2. Water ring compression: Send the calcium carbide furnace tail gas in the carbon monoxide gas tank into the water ring compressor to pressurize to 30KPa;

[0035] S3. Wet dedusting: Send the calcium carbide furnace tail gas compressed by the water ring into the packing tower with the Pall ring inside. The calcium carbide furnace tail gas enters from the lower part, and is carried out with the cold water entering the middle and upper part of the packing tower until the dust in the calcium carbide furnace tail gas Detox to 20mg / M 3 the following;

[0036] S4. Gas compression: Send the calcium carbide furnace tail gas after wet dedusting into the ...

Embodiment 2

[0044] A new process for preparing high-purity carbon monoxide by temperature-controlled transformation, comprising the following steps:

[0045] S1. Buffer storage: Send the tail gas of the calcium carbide furnace into the carbon monoxide gas holder for buffering, mixing and storage;

[0046] S2. Water ring compression: Send the calcium carbide furnace tail gas in the carbon monoxide gas tank into the water ring compressor to pressurize to 60KPa;

[0047] S3. Wet dedusting: Send the calcium carbide furnace tail gas compressed by the water ring into the packing tower with the Pall ring inside. The calcium carbide furnace tail gas enters from the lower part, and is carried out with the cold water entering the middle and upper part of the packing tower until the dust in the calcium carbide furnace tail gas Detox to 20mg / M 3 the following;

[0048] S4. Gas compression: send the calcium carbide furnace tail gas after wet dedusting into the carbon monoxide compressor, so that the...

Embodiment 3

[0056]A new process for preparing high-purity carbon monoxide by temperature-controlled transformation, comprising the following steps:

[0057] S1. Buffer storage: Send the tail gas of the calcium carbide furnace into the carbon monoxide gas holder for buffering, mixing and storage;

[0058] S2. Water ring compression: send the calcium carbide furnace tail gas in the carbon monoxide gas tank into the water ring compressor to pressurize to 50KPa;

[0059] S3. Wet dedusting: Send the calcium carbide furnace tail gas compressed by the water ring into the packing tower with the Pall ring inside. The calcium carbide furnace tail gas enters from the lower part, and is carried out with the cold water entering the middle and upper part of the packing tower until the dust in the calcium carbide furnace tail gas Detox to 20mg / M 3 the following;

[0060] S4. Gas compression: Send the calcium carbide furnace tail gas after wet dedusting to the carbon monoxide compressor, so that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com