System and method for preparing methanol by deeply purifying coke oven gas

A coke oven gas and deep purification technology, applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve the problems of fine desulfurization desulfurizer failure, increased operating costs, and stable operation of the affected system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

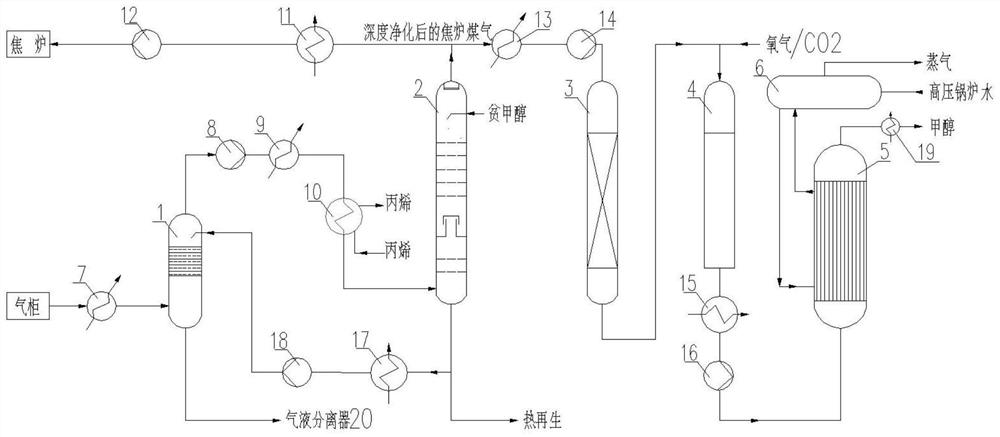

[0031] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

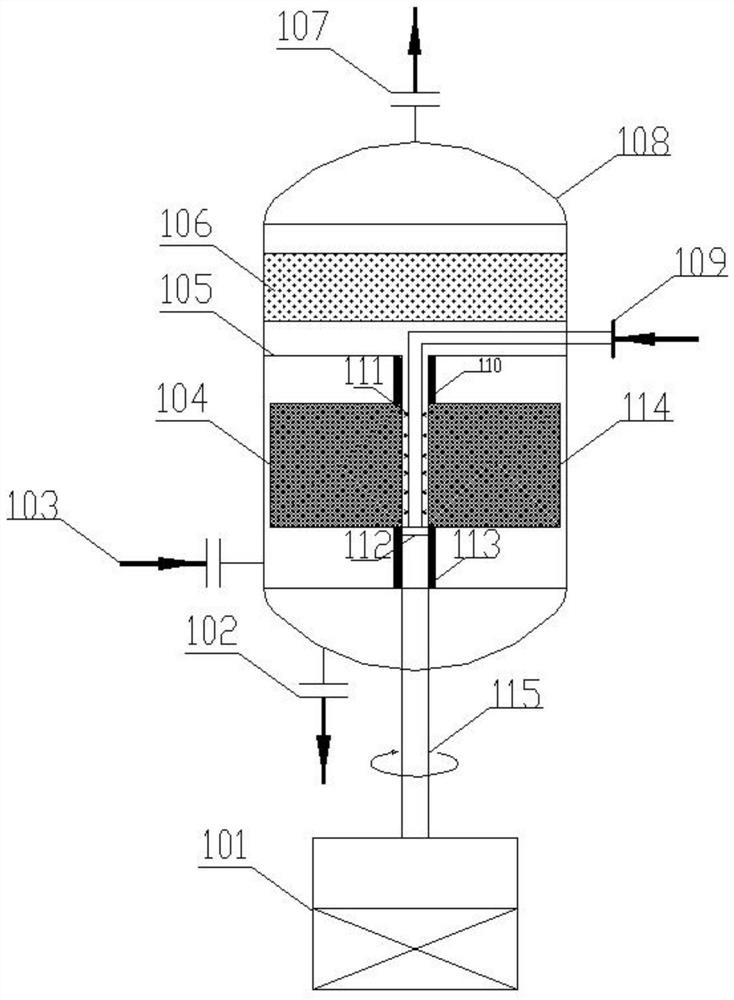

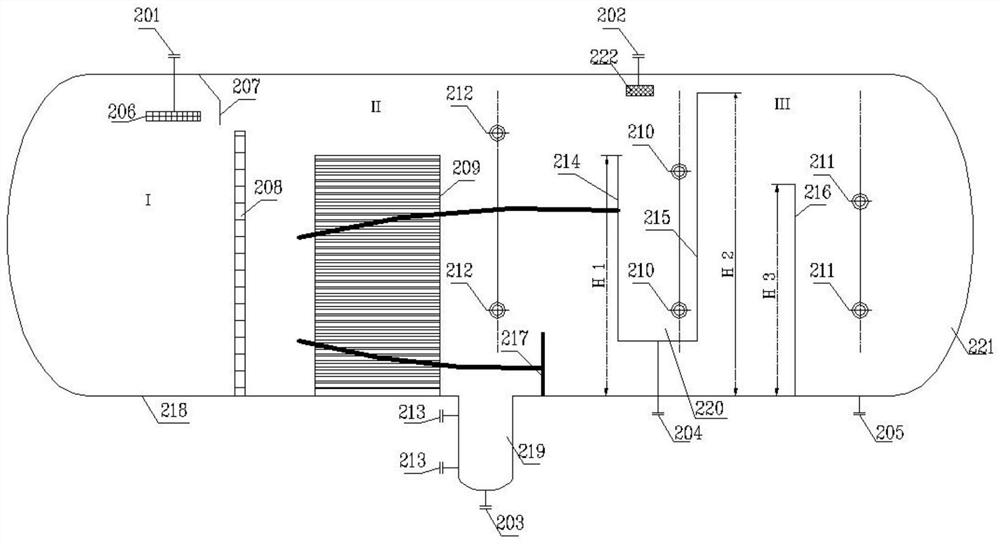

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a system for deep purification of coke oven gas to produce methanol, which includes a pre-washing tower 1, a desulfurization tower 2, a fine desulfurization tower 3, a reformer 4, a methanol synthesis tower 5 and a steam drum 6, The pre-washing tower 1 is a supergravity rotating device, wherein: the gas cabinet is connected to the gas phase inlet 103 at the bottom of the pre-washing tower 1 through the first heat exchanger 7, and the liquid phase outlet 102 at the bottom of the pre-washing tower 1 is connected to the gas-liquid separation device 20 connection, the gas outlet 107 at the top of the prewashing tower 1 is connected to the air inlet at the bottom of the desulfurization tower 2 through the first compressor 8, the second heat exchanger 9 and the third heat exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com