High energy beam polysilicon purifying device

A technology of polysilicon and high-energy beams, which is applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as environmental pollution, high cost, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

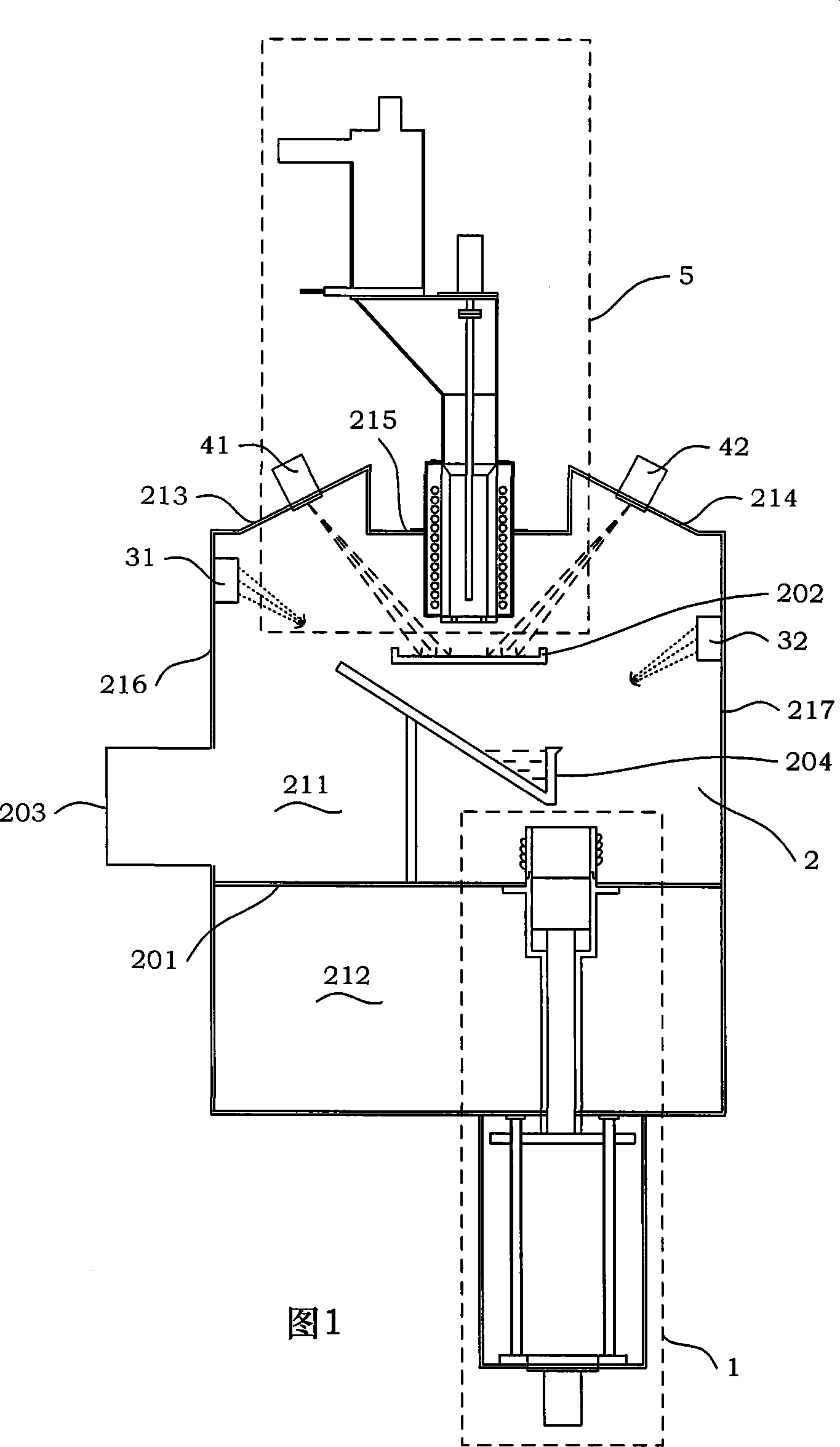

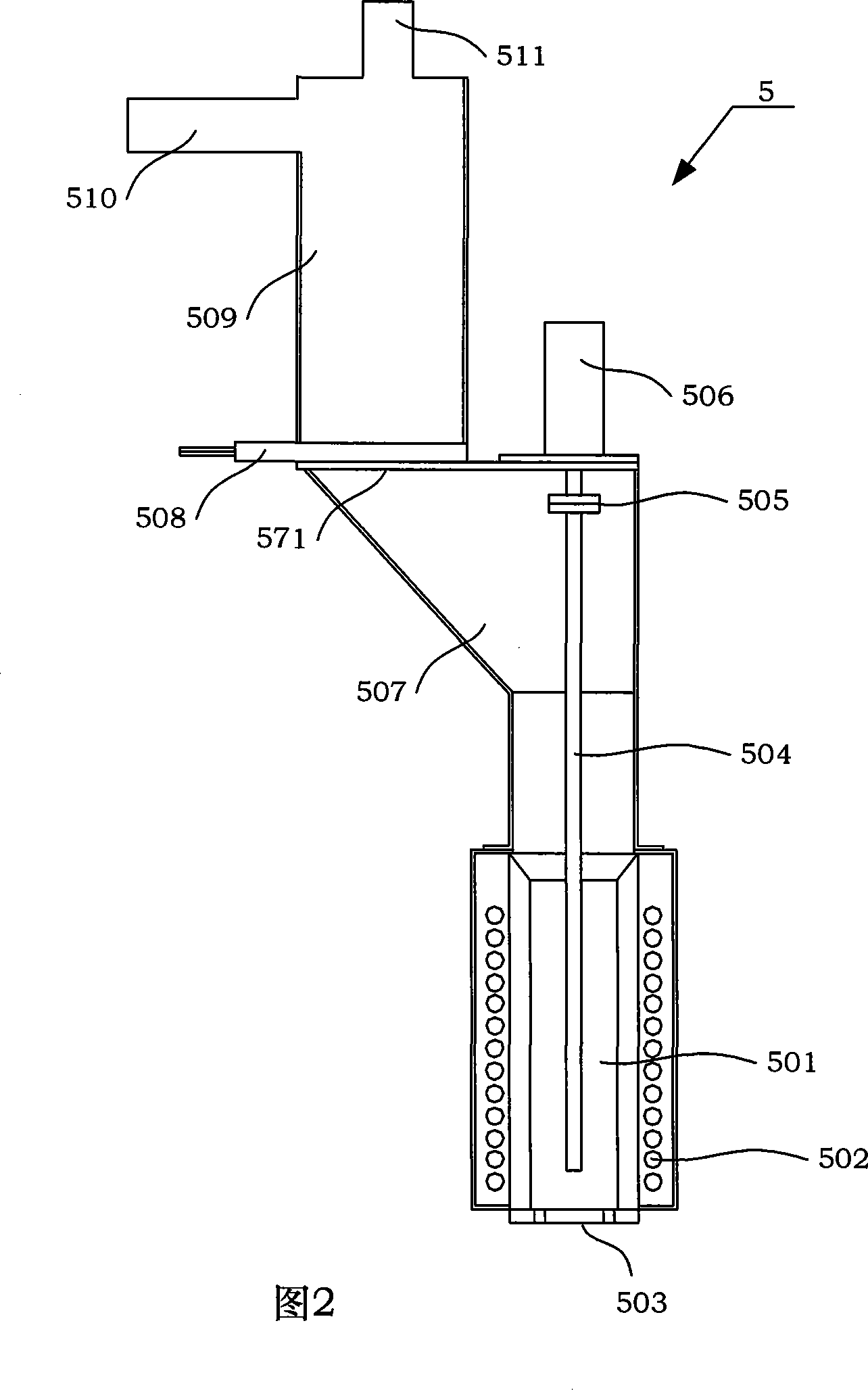

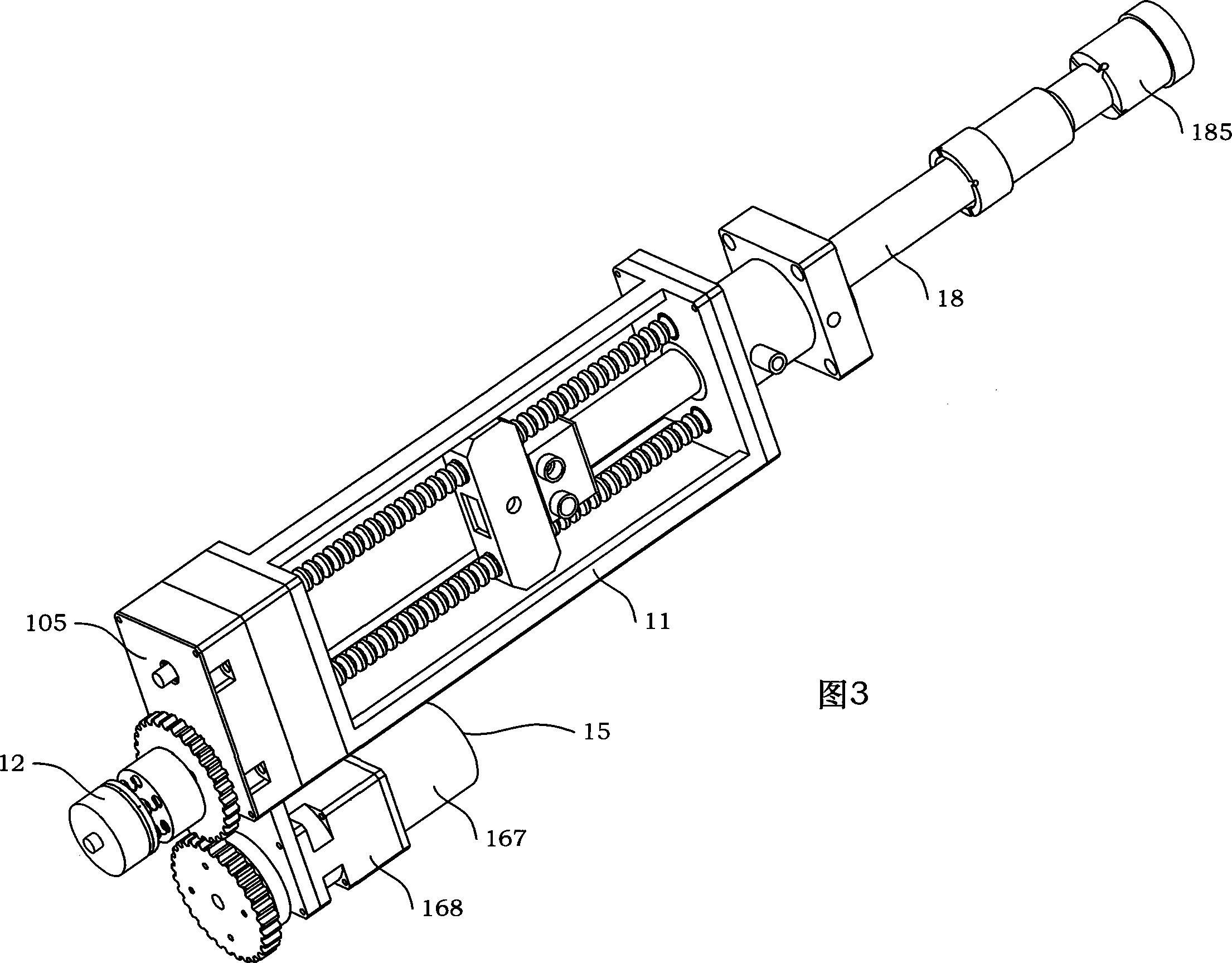

[0021] Referring to Fig. 1, the present invention is a four-in-one high-energy beam polysilicon purification device integrating isovacuum electromagnetic induction smelting, electron beam smelting, ion smelting, and directional solidification. The purification device includes a directional solidification unit 1, a vacuum Chamber 2, plasma smelting unit, electron beam smelting unit, vacuum electromagnetic induction smelting unit 5; vacuum electromagnetic induction smelting unit 5 is installed on the concave surface 215 of vacuum chamber 2; A electron gun 41 of electron beam smelting unit is installed in vacuum chamber 2 On the left inclined plane 213 of the vacuum chamber 2, the B electron gun 42 is installed on the right inclined plane 214 of the vacuum chamber 2; On the right housing 217 ; the connection seat 182 of the directional solidification unit 1 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com