Preparation method of polymer grade piperyene

A technology of pentadiene and polymerization grade, applied in the field of preparation of polymer grade piperylene, can solve the problems that separation technology is difficult to purify and purify, uneconomical, very high in equipment requirements and operating process conditions, and achieves high purification accuracy. , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

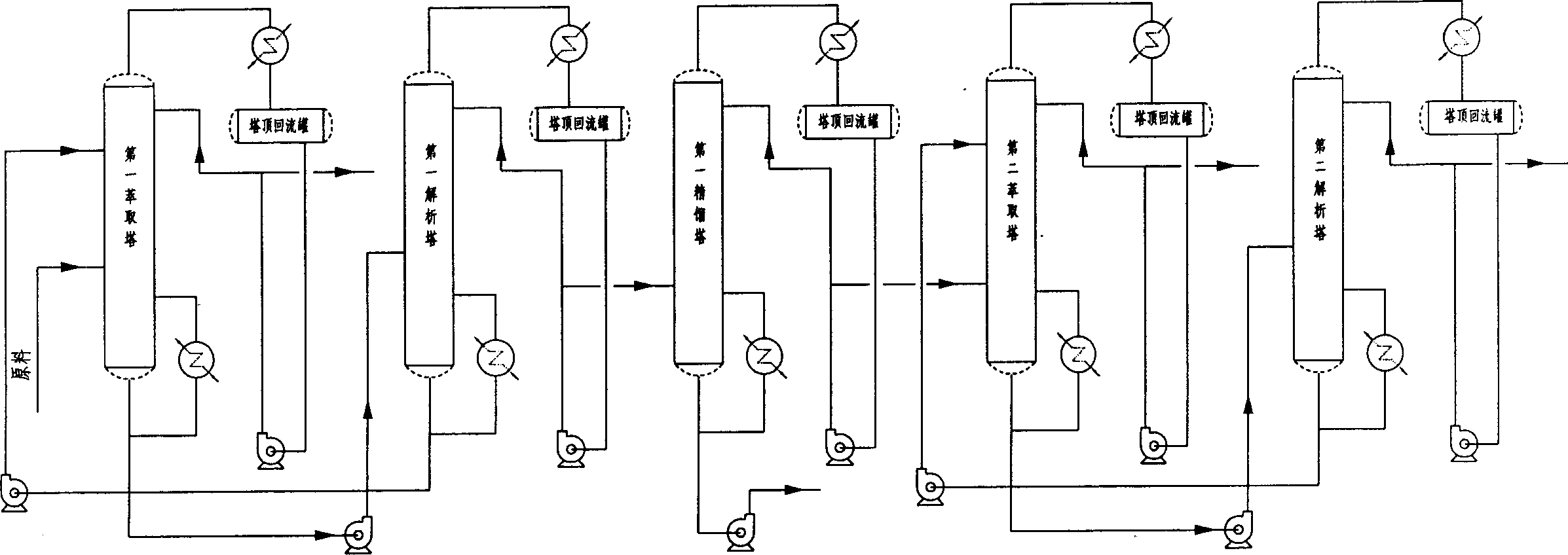

Embodiment 1

[0027] The piperylene raw material enters the first extraction tower in the presence of the polymerization inhibitor SP-731, the operating pressure is: 0.12Mpa, the temperature is 50°C, the reflux ratio is 6, and the feed temperature of the extraction agent dimethylformamide added to the top of the tower is first Preheating to 60°C, the volume ratio to the raw material is 4:1, cyclopentene, cyclopentane and light components are removed from the top of the tower, and the extractant and piperylene materials are obtained from the tower reactor; the first extraction tower The materials in the still enter the first desorption tower, the operating pressure is normal pressure, the temperature is 40°C, and the reflux ratio is 1. High-purity piperylene containing cyclopentadiene and alkyne is obtained at the top of the tower, and the extractant in the tower is returned to the first extraction tower for circulation Use; the high-purity piperylene at the top of the first analysis tower en...

Embodiment 2

[0029] The piperylene raw material enters the first extraction tower in the presence of the polymerization inhibitor SP-731, the operating pressure is: 0.18Mpa, the temperature is 135°C, the reflux ratio is 10, and the feed temperature of the extractant dimethylformamide added to the top of the tower is first Preheating to 90°C, with a volume ratio of 10:1 to the amount of raw material, cyclopentene, cyclopentane and light components are removed from the top of the tower, and the extractant and piperylene materials are obtained from the tower reactor; the first extraction tower The materials in the still enter the first desorption tower, the operating pressure is normal pressure, the temperature is 160°C, and the reflux ratio is 5. High-purity piperylene containing cyclopentadiene and alkynes is obtained at the top of the tower, and the extraction agent in the tower is returned to the first extraction tower for circulation Use; the high-purity piperylene at the top of the first...

Embodiment 3

[0031] The piperylene raw material enters the first extraction tower in the presence of the polymerization inhibitor SP-731, the operating pressure is: 0.15Mpa, the temperature is 85°C, the reflux ratio is 8, and the feed temperature of the extraction agent dimethylformamide added to the top of the tower is first Preheating to 70°C, the volume ratio to the raw material is 7:1, cyclopentene, cyclopentane and light components are removed from the top of the tower, and the extractant and piperylene materials are obtained from the tower reactor; the first extraction tower The material in the kettle enters the first desorption tower, the operating pressure is normal pressure, the temperature is 100°C, and the reflux ratio is 3. High-purity piperylene containing cyclopentadiene and alkyne is obtained at the top of the tower, and the extractant in the tower is returned to the first extraction tower for circulation Use; the high-purity piperylene at the top of the first analysis tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com