Method for preparing isomeric stearic acid by means of freezing crystallization and fractionation

A technology for isomeric stearic acid and freezing crystallization, which is applied in the field of preparing isomeric stearic acid, can solve the problems of incomplete cooling crystallization, environmental protection, potential safety hazards, weak control of cooling, etc., and achieves low labor cost and the number of equipment. Less time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of cryogenic crystallization fractionation isomeric stearic acid, comprises the steps:

[0024] S1 raw material pretreatment: Put the aliphatic carboxylic acid after the polymerization reaction into the dehydrator for dehydration and removal of impurities;

[0025] S2 cooling and crystallization: Put the pretreated material in S1 into a low-temperature freezer, first cool down the low-temperature freezer to 0°C, and maintain this temperature for 12 hours; then cool the low-temperature freezer to -5°C, and maintain The temperature was 12 hours; finally, the low-temperature refrigerator was cooled to -10°C and maintained at this temperature for 48 hours; crystallized polymeric aliphatic carboxylic acids were obtained;

[0026] S3 low-temperature pressing: the crystallized polymeric fatty carboxylic acid is placed in the press tray of the press for pressing, and the press includes multi-layer press trays from top to bottom, and the crystallized...

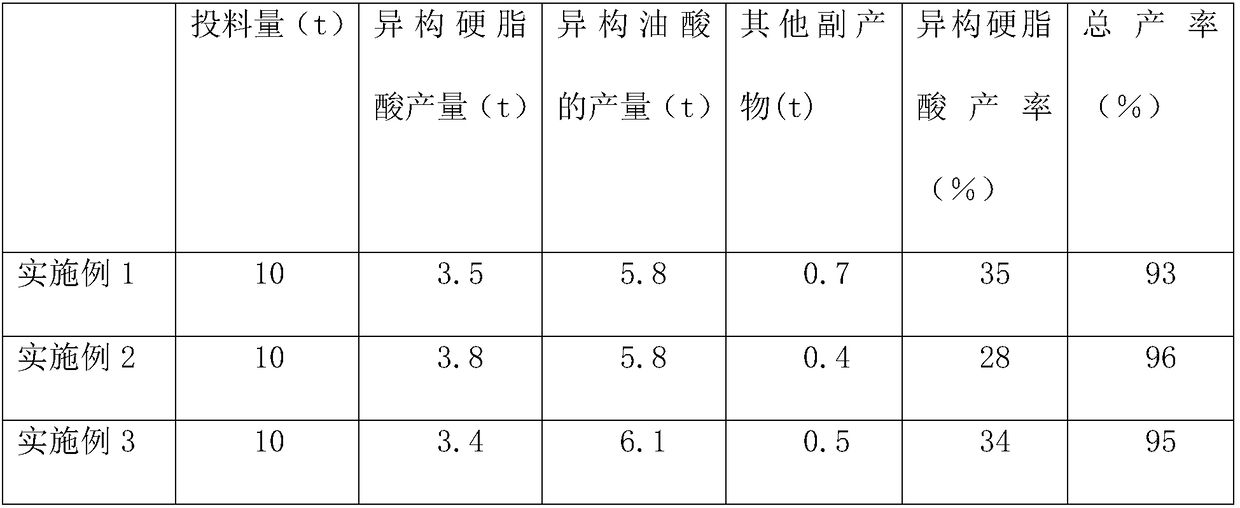

Embodiment 1

[0033] A kind of preparation method of cryogenic crystallization fractionation isomeric stearic acid, comprises the steps:

[0034] S1 Pretreatment of 10 tons of raw materials: put the aliphatic carboxylic acid after the polymerization reaction into a dehydrator for dehydration and removal of impurities, and control the temperature in the dehydrator at 100°C;

[0035] S2 cooling and crystallization: Put the pretreated material in S1 into a low-temperature freezer, first cool down the low-temperature freezer to 0°C, and maintain this temperature for 12 hours; then cool the low-temperature freezer to -5°C, and maintain This temperature is 10h; finally, the temperature of the low-temperature refrigerator is lowered to -10°C, and the temperature is maintained for 50h; crystallized polymeric aliphatic carboxylic acid is obtained;

[0036] S3 Low-temperature pressing: placing the crystallized polymeric aliphatic carboxylic acid in a pressing tray of an extruding machine for pressing...

Embodiment 2

[0043] A kind of preparation method of cryogenic crystallization fractionation isomeric stearic acid, comprises the steps:

[0044] S1 Pretreatment of 10 tons of raw materials: put the aliphatic carboxylic acid after the polymerization reaction into a dehydrator for dehydration and removal of impurities, and control the temperature in the dehydrator at 105°C;

[0045]S2 cooling crystallization: put the pretreated material in S1 into a low-temperature freezer, first cool down the low-temperature freezer to 0°C, and maintain this temperature for 14 hours; then cool down the low-temperature freezer to -5°C, and maintain The temperature was 12 hours; finally, the low-temperature refrigerator was cooled to -10°C and maintained at this temperature for 48 hours; crystallized polymeric aliphatic carboxylic acids were obtained;

[0046] S3 Low-temperature pressing: placing the crystallized polymeric aliphatic carboxylic acid in a pressing tray of an extruding machine for pressing, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com