Centrifugal type preposed filtering device

A pre-filtration and centrifugal technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low primary filtration efficiency, low purification efficiency, energy waste, etc., to reduce the burden of filtration, installation and maintenance Convenience and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

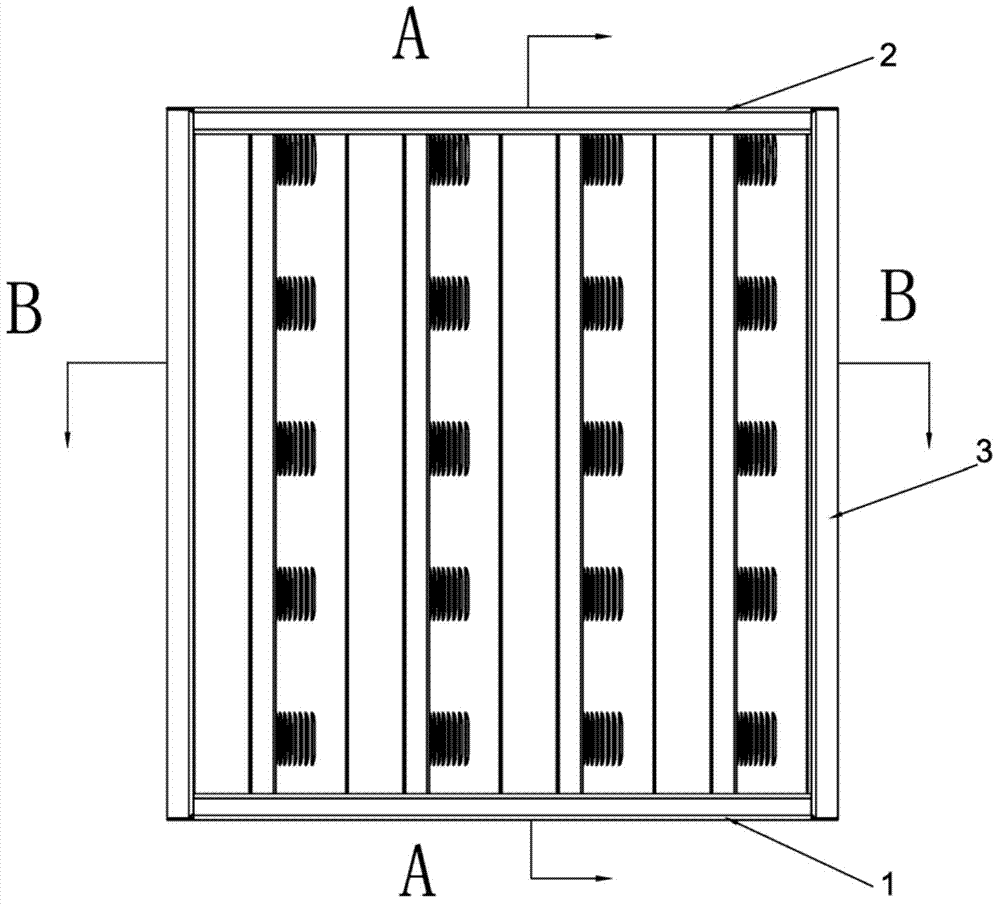

[0020] Such as Figure 1-3 As shown, a centrifugal pre-filtering device includes a frame surrounded by a top plate 2, a side plate 3 fixedly connected to the top plate 2, and a bottom plate 1 fixedly connected to the side plate 3;

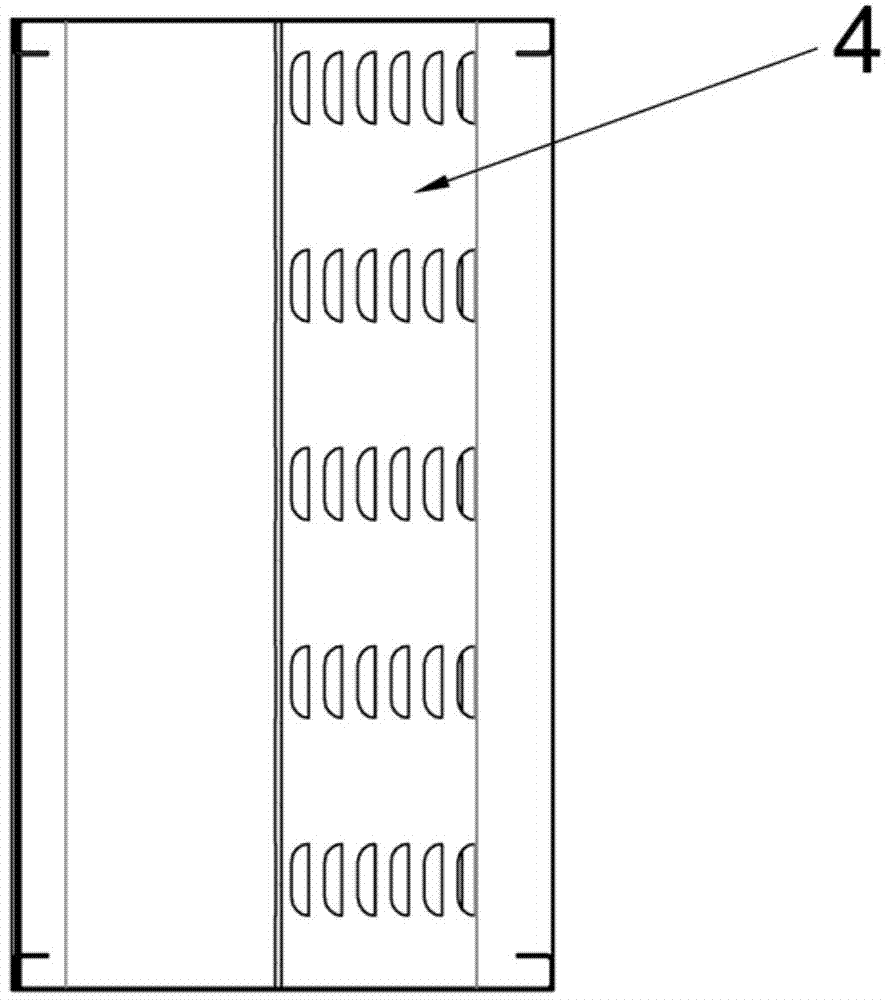

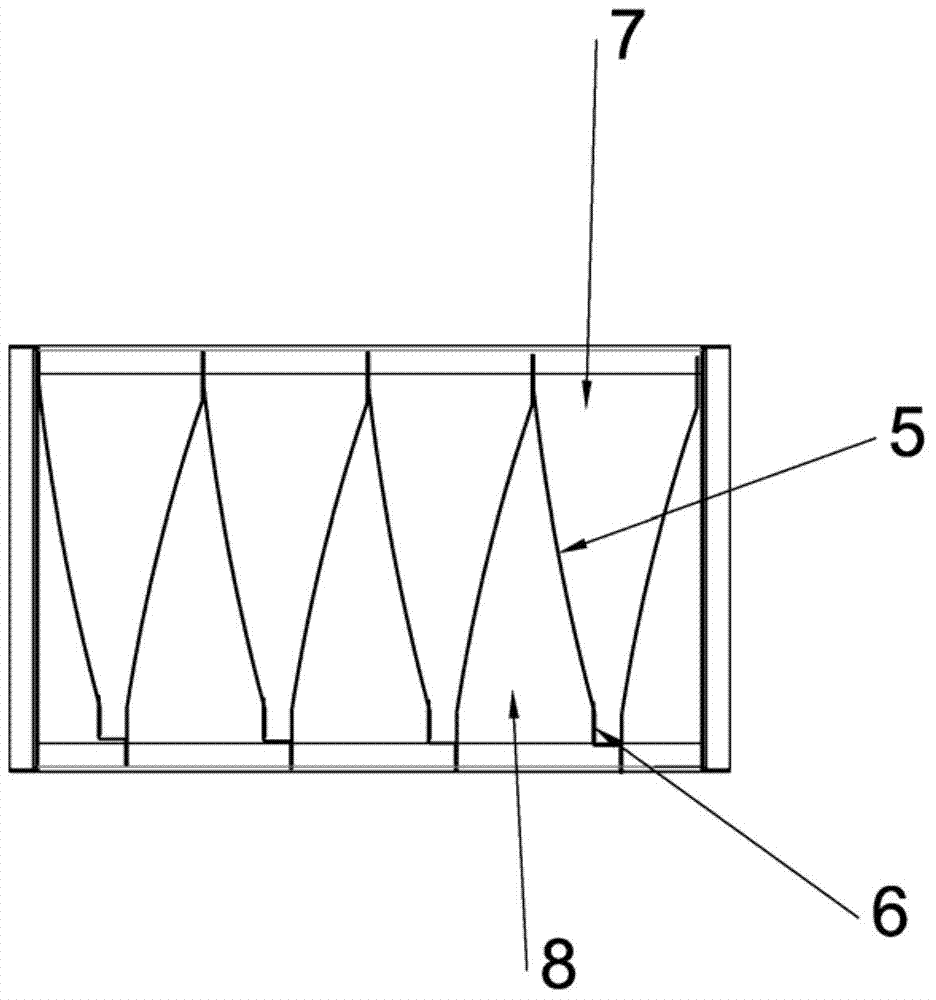

[0021] It also includes a filter unit. The filter unit includes a blade orifice plate 4, a blind plate 5, and a Z-slot plate 6. One side of the blade orifice plate 4 is connected to one side of the blind plate 5, and the Z-slot plate is rivets The clamp is fixed between the two connecting edges of the blade orifice plate and the blind plate 5. The other side of the blade orifice plate 4 is connected to the adjacent blind plate of the blind plate 5, and the blind plate 5 and the blade orifice plate 4 are in sequence. Connect to form an M-shaped structure;

[0022] The top plate 2 and the bottom plate 1 are provided with fixed matching grooves, and the filter unit is inserted into the fixed matching grooves to be fixed, and sealed by polyurethane potting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com