System and method for removing chlorine salt from waste incineration fly ash

A waste incineration fly ash and chlorine salt technology, which is applied to the removal of alkali metal chlorides, solid waste, calcium/strontium/barium chloride, etc., can solve the problem that the chlorine content cannot meet resource utilization, the cost of solid-liquid separation increases, Problems such as low utilization rate of water resources, to achieve the effect of reducing the possibility of heavy metal release, good environmental and economic benefits, and reducing obstacles to subsequent resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

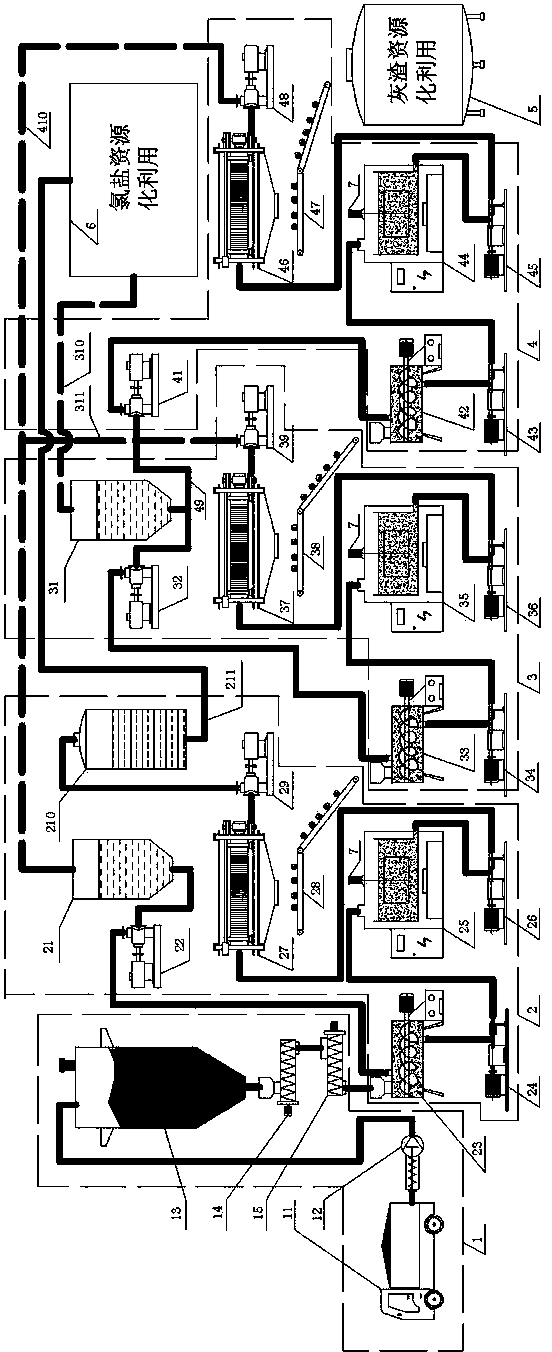

[0044] figure 1 It shows the waste incineration fly ash chlorine salt removal system of the present invention, the waste incineration fly ash chlorine salt removal system includes a fly ash storage and transportation device 1, a first ultrasonic cleaning device 2, a second ultrasonic cleaning device 3, a third ultrasonic cleaning device Device 4, ash resource utilization device 5 (specifically, a high-pressure reactor) and a chlorine salt resource utilization device 6 (specifically, a boiler, or a solar evaporation device);

[0045] The fly ash storage and transportation device 1 is connected to the first ultrasonic cleaning device 2;

[0046] Between the first ultrasonic cleaning device 2 and the second ultrasonic cleaning device 3, there is a first conveying device 28 (specifically a belt conveyor) for transferring the filter cake produced by the first ultrasonic cleaning device 2 to the second ultrasonic cleaning device 3 ), between the second ultrasonic cleaning device 3 ...

Embodiment 2

[0068] A method for removing chlorine salts from garbage incineration fly ash of the present invention, the system for removing chlorine salts from garbage incineration fly ash is the same as that in Example 1, and the operation steps are basically the same as in Example 1, except that there are differences in parameters. The specific parameters of this embodiment as follows:

[0069] S1: The initial moisture content of the fly ash is 3.2%, and the CaO content is 13.7wt%. The washing time is 1 hour, and the ultrasonic washing temperature is 4°C to 50°C (the temperature will rise during the ultrasonic process, the same below);

[0070] S2: When the water recovered and condensed in the second ultrasonic cleaning device 3 is mixed with the filter cake delivered by the first ultrasonic cleaning device 2, the fly ash in step S1 is used as a reference to measure, and the mass ratio of the fly ash to the recovered condensed water is 1:3; the time of the second ultrasonic washing is ...

Embodiment 3

[0074] A method for removing chlorine salts from garbage incineration fly ash of the present invention, the system for removing chlorine salts from garbage incineration fly ash is the same as that in Example 1, and the operation steps are basically the same as in Example 1, except that there are differences in parameters. The specific parameters of this embodiment as follows:

[0075] S1: The initial moisture content of the fly ash is 3.2%, and the CaO content is 20wt%. The time of washing is 1h, and the temperature of ultrasonic washing is 4℃~50℃;

[0076] S2: When the water recovered and condensed in the second ultrasonic cleaning device 3 is mixed with the filter cake delivered by the first ultrasonic cleaning device 2, the fly ash in step S1 is used as a reference to measure, and the mass ratio of the fly ash to the recovered condensed water is 1:5; the time of the second ultrasonic washing is 1h, and the temperature of ultrasonic washing is 4℃~50℃;

[0077] S3: When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com