Automatic supply system of composite spray cooling oil for machining

A technology of spray cooling and mechanical processing, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of time-consuming and cumbersome, etc., and achieve the effects of improving anti-corrosion performance, increasing production efficiency, and reducing chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Attached below Figure 1 to Figure 4 , and specific embodiments will further illustrate the present invention.

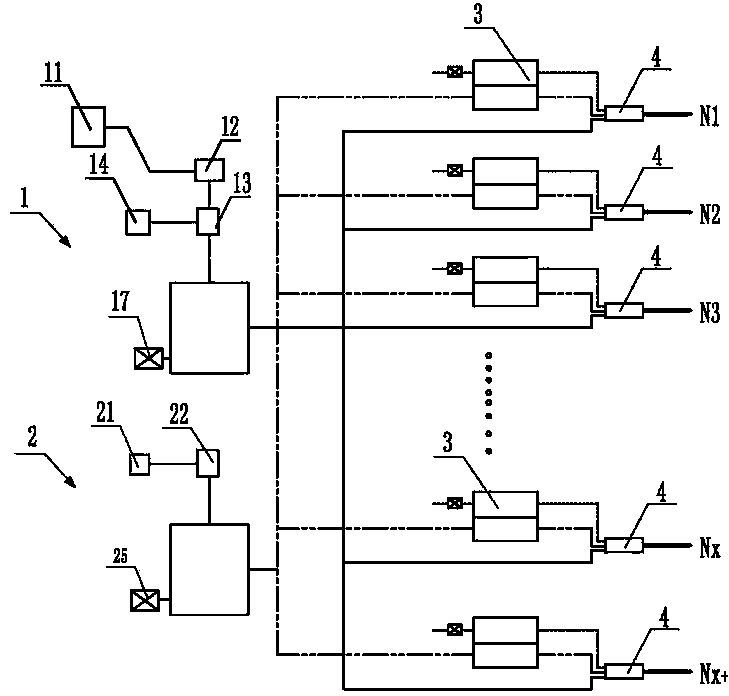

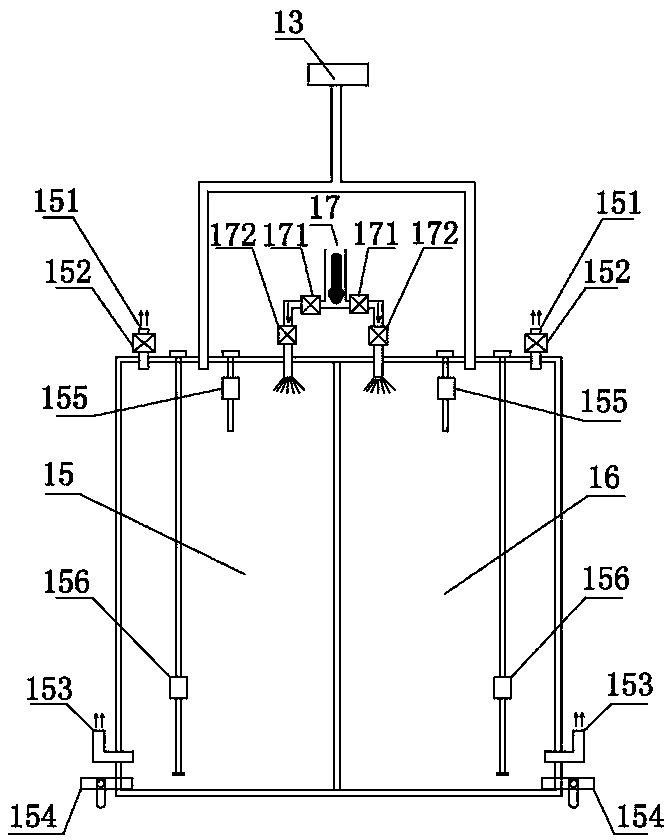

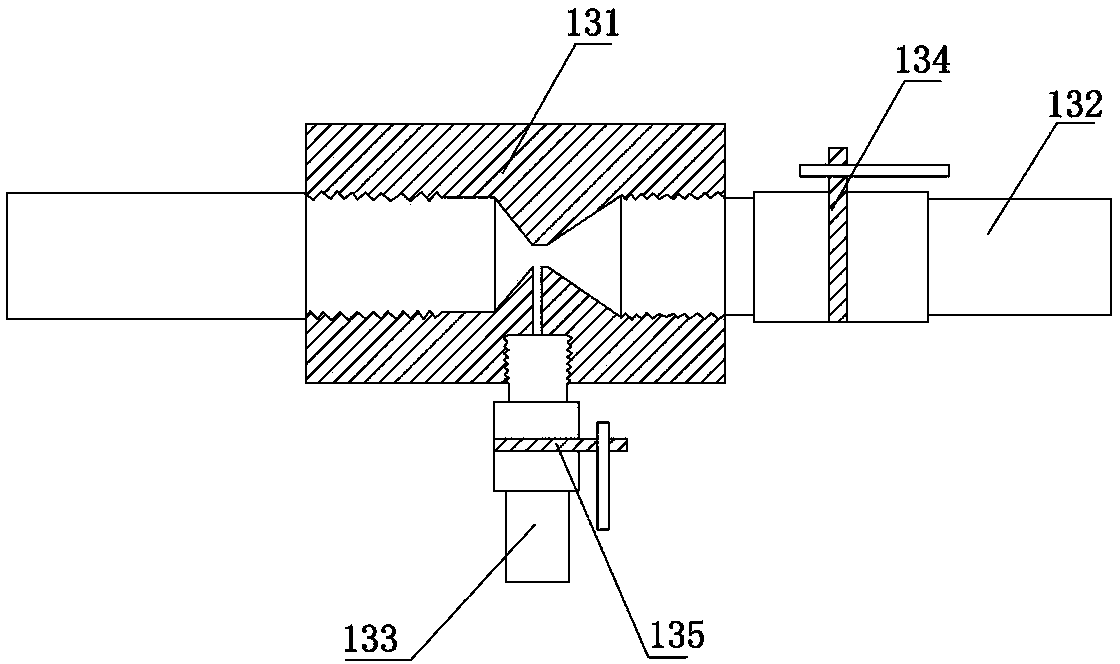

[0044] Such as Figure 1 to Figure 4 As shown, the composite spray cooling oil automatic supply system for mechanical processing includes an automatic water supply system 1, an automatic oil supply system 2, a minimum quantity lubrication cooling system 3 and a composite atomizing nozzle 4, and the water outlet of the automatic water supply system 1 The liquid inlet of the composite atomizing nozzle 4 is connected through the conveying pipe, the oil outlet of the automatic oil supply system 2 is connected with the liquid inlet of the minimum quantity lubrication cooling system 3 through the conveying pipe, and the liquid outlet of the minimum quantity lubrication cooling system 3 The mouth is connected with the liquid inlet of the composite atomizing nozzle 4.

[0045] In this embodiment, the automatic water supply system 1 automatically supplies water to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com