Production method for improving hypochlorous acid solution stability

A technology of hypochlorous acid solution and production method, which is applied in electrolysis process, electrolysis components, etc., and can solve problems such as inability to store for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

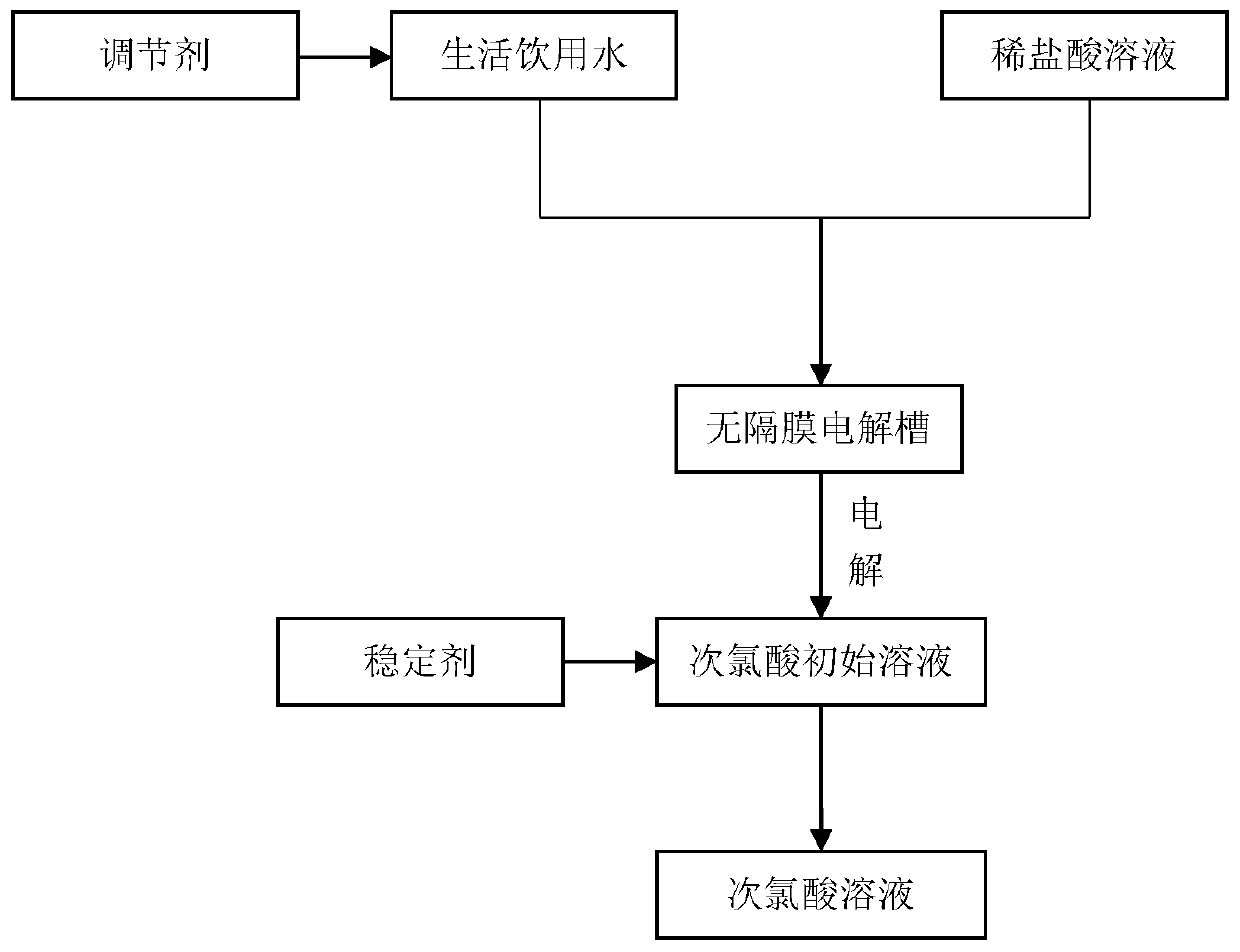

[0029] Embodiment 1. improves the production method of hypochlorous acid solution stability.

[0030] 1) Add 10 ppm sodium bicarbonate to domestic water to obtain solution A.

[0031] 2) Food-grade hydrochloric acid is used as raw material to prepare dilute hydrochloric acid solution with a volume concentration of 4%, which is used as the electrolytic raw material of the hypochlorous acid generator.

[0032] 3) Dilute hydrochloric acid solution and the solution A obtained in step 1) enter the electrolytic cell without diaphragm inside the hypochlorous acid generator through the pump body (water pressure 25kpa, dilute hydrochloric acid solution pump pulse 15ms), after mixing, electrolysis (electrolysis current 3.0 A) generate hypochlorous acid initial solution, the electrolytic reaction equation is: 2HCL+H 2 O→HCL+HOCL+H 2 ↑.

[0033] 4) Add 50 ppm of sodium sulfamate to the hypochlorous acid initial solution to generate hypochlorous acid solution.

[0034] The physical and...

Embodiment 2

[0035] Embodiment 2. improves the production method of hypochlorous acid solution stability.

[0036] 1) Add 50 ppm potassium carbonate to domestic water to obtain solution A.

[0037] 2) Food-grade hydrochloric acid is used as raw material to prepare dilute hydrochloric acid solution with a volume concentration of 9%, which is used as the electrolysis raw material of the hypochlorous acid generator.

[0038] 3) The dilute hydrochloric acid solution and the solution A obtained in step 1) enter the electrolytic cell without a diaphragm inside the hypochlorous acid generator through the pump body (water pressure 30kpa, and the dilute hydrochloric acid solution pump pulse 10ms), after mixing, electrolysis (electrolysis current 2.8 A) generate hypochlorous acid initial solution, the electrolytic reaction equation is: 2HCL+H 2 O→HCL+HOCL+H 2 ↑.

[0039] 4) Add 300 ppm of sodium citrate to the initial hypochlorous acid solution to generate hypochlorous acid solution.

[0040] Th...

Embodiment 3

[0041] Embodiment 3. improve the production method of hypochlorous acid solution stability.

[0042] 1) Add 25 ppm potassium carbonate to domestic water to obtain solution A.

[0043] 2) Prepare a dilute hydrochloric acid solution with a volume concentration of 12% using food-grade hydrochloric acid as the raw material for the electrolysis of the hypochlorous acid generator.

[0044] 3) The dilute hydrochloric acid solution and the solution A obtained in step 1) enter the electrolytic cell without diaphragm inside the hypochlorous acid generator through the pump body (water pressure 50kpa, and the dilute hydrochloric acid solution pump pulse 8ms), after mixing, electrolysis (electrolysis current 3.0 A) generate hypochlorous acid initial solution, the electrolytic reaction equation is: 2HCL+H 2 O→HCL+HOCL+H 2 ↑

[0045] 4) Add 150 ppm of sodium silicate to the initial hypochlorous acid solution to generate hypochlorous acid solution.

[0046] The physical and chemical indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com