Low-chloride phosphorus potassium fertilizer and preparation method thereof

A technology for low-chlorine-phosphorus-potassium fertilizer and chlorine-based fertilizer, applied in the field of low-chlorine-phosphorus-potassium fertilizer and its preparation, can solve the problems of high total nutrients of fertilizers, single phosphorus fertilizer nutrients, complicated preparation process, etc. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

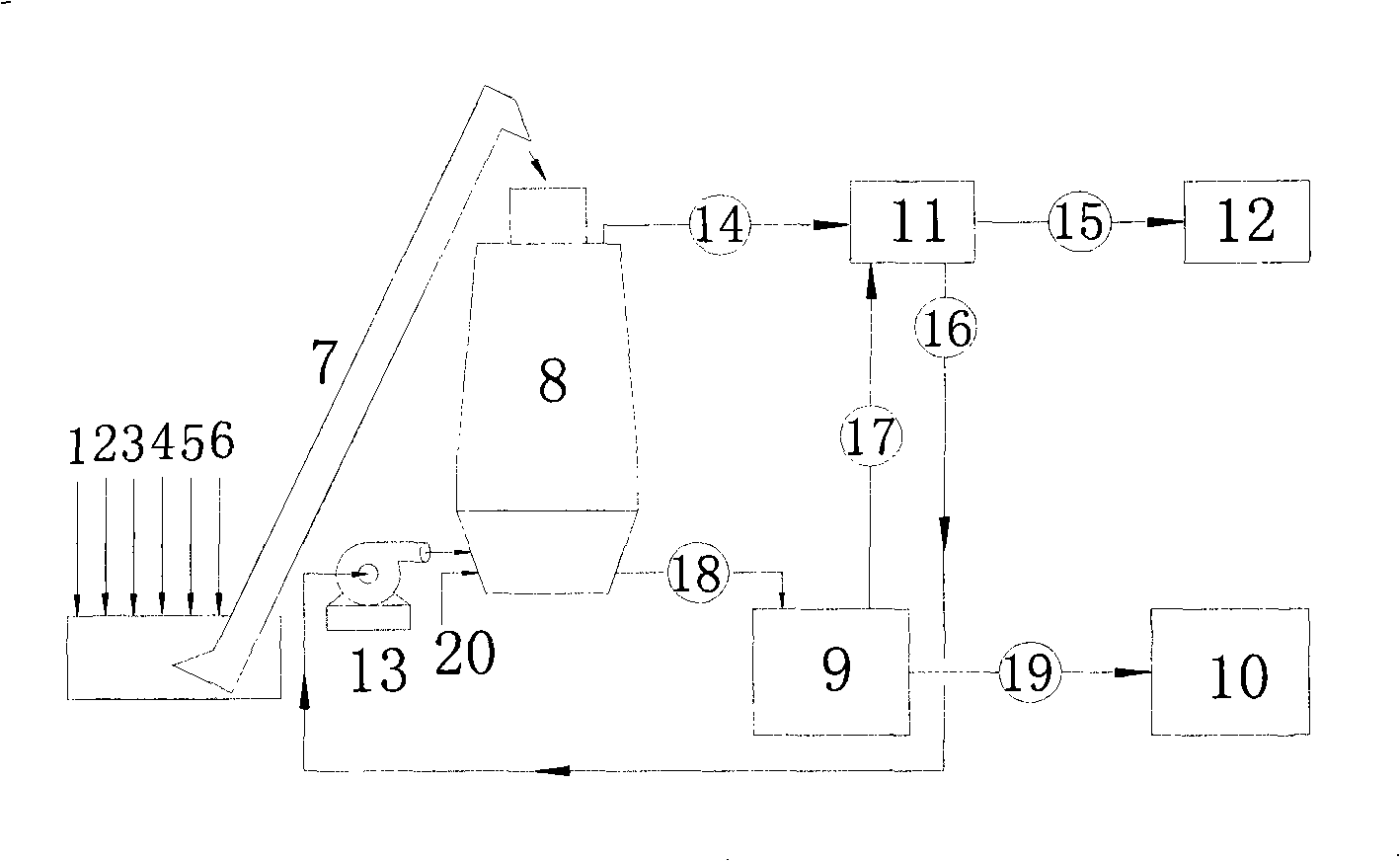

[0040] like figure 1 Shown is a schematic flow chart of the method of this embodiment. In the figure, 1 is potassium chloride, 2 is phosphate rock powder, 3 is quartz sand, 4 is potassium feldspar, 5 is boric anhydride, 6 is coal burning; 7 is bucket elevator, 8 is blast furnace, and 9 is water quenching tank , 10 is the crusher, 11 is the hot blast stove, 12 is the tail gas washing system, 13 is the fan, 14 is the blast furnace tail gas, 15 is the hot blast stove tail gas, 16 is the preheated air and water vapor, 17 is the water vapor produced by water quenching, 18 is high-temperature melt slurry, 19 is phosphorus and potassium fertilizer particles after water quenching, and 20 is atomized heavy oil or natural gas.

[0041] Phosphate rock powder is 10.1 tons / hour, quartz sand is 2.4 tons / hour, potassium chloride is 4.5 tons / hour, potassium feldspar is 0.5 tons / hour, boric anhydride is 0.2 tons / hour, and coal is 4.2 tons / hour. After mixing, it is sent to the top of blast fu...

Embodiment 2

[0043] Phosphate rock powder is mixed at 10.1 tons / hour, quartz sand is 2.8 tons / hour, potassium chloride is 3.5 tons / hour, potassium-containing sandstone is 0.6 tons / hour, boric anhydride is 0.6 tons / hour, and these raw materials are mixed and fed by bucket elevator 7 There are 8 material inlets in the open hearth furnace. Natural gas is mixed and burned at the entrance of the open hearth furnace at 3.0 tons / hour, oxygen-enriched air and water vapor (introduced at 0.8 tons / hour). The high temperature gas melts the mixed materials and reacts. , The average residence time of the reaction materials in the open hearth furnace is 10 hours. The high-temperature molten slurry is quenched with water, and after solidification, it is crushed and packaged to become the finished phosphorus and potassium fertilizer. K 2 O% content 17.5%, P 2 o 5 % content 23.4%.

Embodiment 3

[0045] Phosphate rock powder is mixed at 10.1 tons / hour, diatomite is 3.5 tons / hour, potassium chloride is 5.0 tons / hour, alunite is 2.0 tons / hour, and boric anhydride is 1.0 tons / hour. 8 material inlets of the electric furnace are fed with steam at 1.0 tons / hour. The temperature of the electric furnace is controlled at 1600°C, and the average residence time of the reaction materials in the open hearth furnace is 3.0 hours. The high-temperature molten slurry is quenched with water, and after solidification, it is crushed and packaged to become the finished phosphorus and potassium fertilizer. K 2 O% content 18.0%, P 2 o 5 % content 17.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com