Novel abrasion resistant silicon-mullite-nitrogen brick for transition zones of rotary cement kiln

A silicon molybdenum brick and silicon carbide technology, which is used in rotary drum furnaces, furnace types, lighting and heating equipment, etc. The effect of reducing the surface temperature of the cylinder, improving work efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Super high alumina bauxite aggregate 0~6mm Al 2 o 3 ≥85% 55%

[0036] Silicon carbide 0~1mm SiC≥95% 3%

[0037] Silicon carbide ≤0.088mm SiC≥95% 8%

[0038] Brown corundum fine powder 5%

[0039] Andalusite Powder 14%

[0041] Ferrosilicon Nitride 0%

[0042] Clay 5%

[0043] Add lignosulfonic acid solution 3%

Embodiment 2

[0045] Super high alumina bauxite aggregate 0~6mm Al 2 o 3 ≥85% 54%

[0046] Silicon carbide 0~1mm SiC≥95% 2%

[0047] Silicon carbide ≤0.088mm SiC≥95% 3%

[0048] Brown corundum fine powder 6%

[0049] Andalusite Powder 14%

[0050]Silicon nitride 7%

[0051] Ferrosilicon Nitride 5%

[0052] Clay 5%

[0053] Add lignosulfonic acid solution 5%

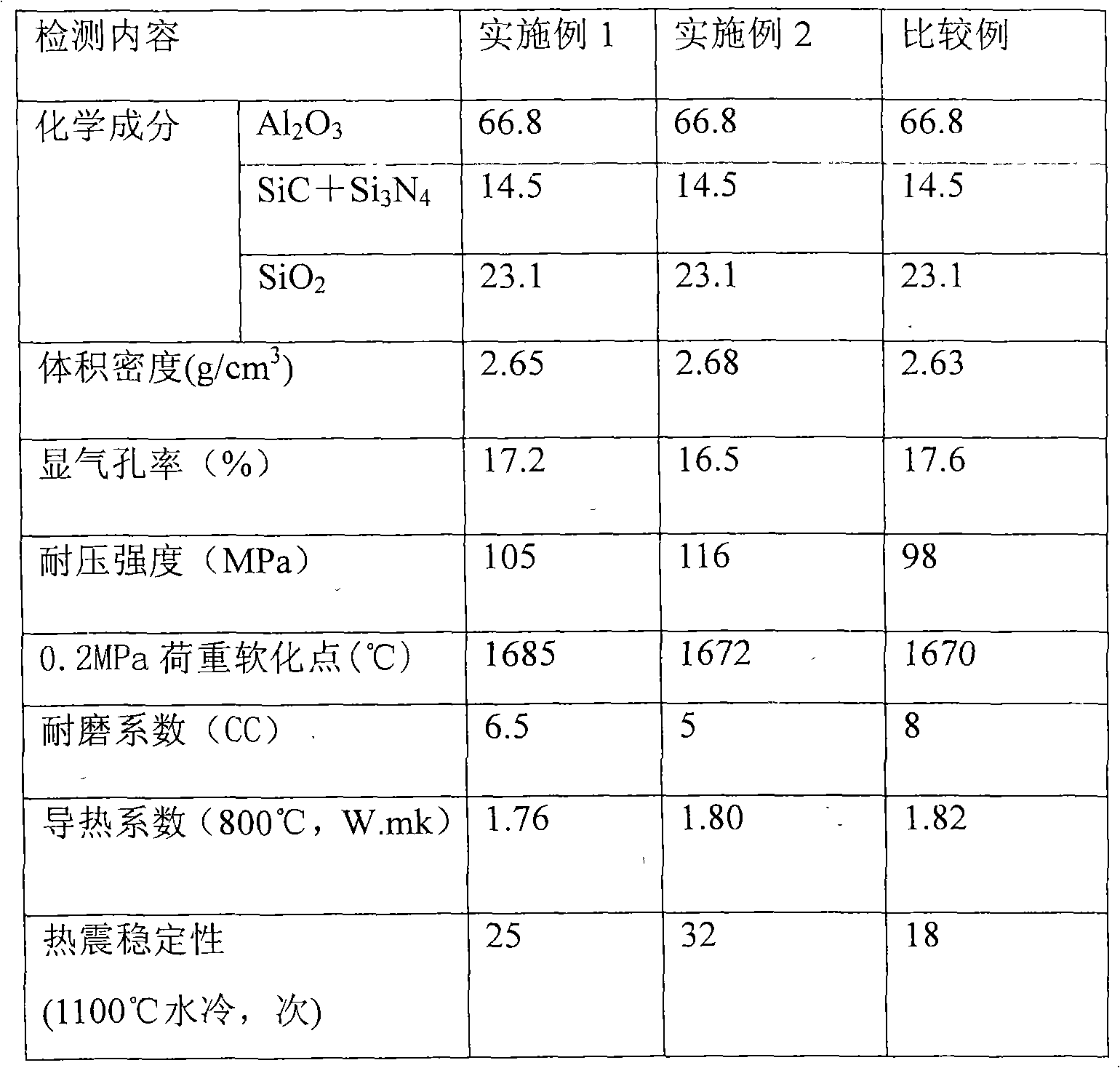

[0054] As can be seen from Table 2, compared with the comparative examples without adding silicon nitride or ferrosilicon nitride, the present invention has low thermal conductivity, high wear resistance, The advantages of alkali corrosion resistance and oxidation resistance greatly improve the working efficiency of cement kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com