Cement presintering production method and system

A production method and pre-sintering technology, applied in cement production, clinker production, lighting and heating equipment, etc., can solve the problem of high power consumption, improve clinker quality, increase cement output, and reduce grinding power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

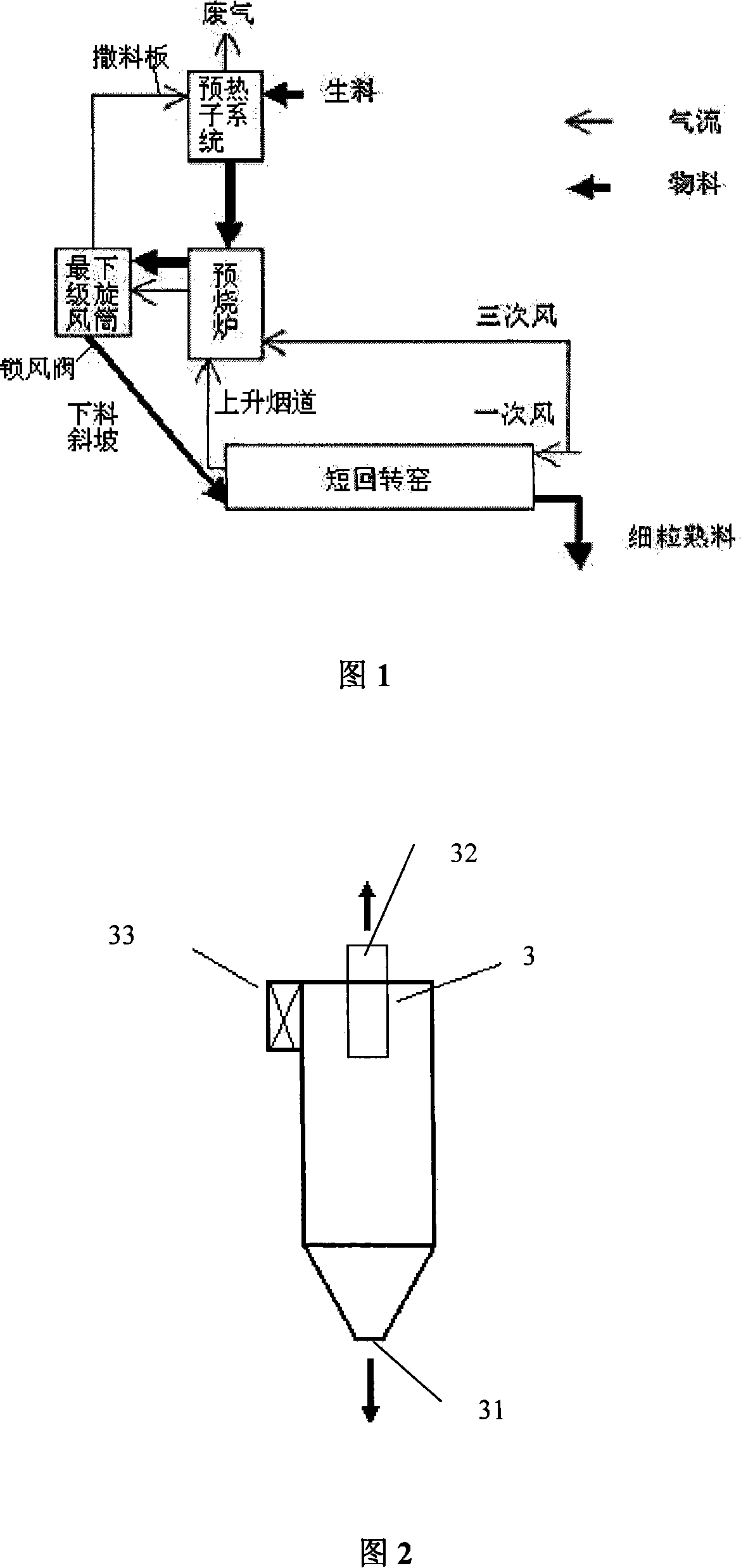

[0016] The technical route of the present invention is to increase the temperature of the material entering the kiln from 900°C to about 1100°C (950-1250°C) in the existing preheating subsystem, that is, to increase the temperature of the material entering the kiln by about 200°C or higher, eliminating the need for cement The heat transfer "bottleneck" of the rotary kiln realizes the rapid firing of cement clinker in the rotary kiln with zero heat consumption or even negative heat consumption, so as to achieve the goals of increasing production, saving energy and improving clinker quality.

[0017] First, the present invention should provide the heat required for the decomposition of residual carbonate in the rotary kiln and the even exothermic reaction temperature of the kiln material. The carbonate decomposition rate of the cement precalcining kiln feed into the kiln is only 90%, and the remaining 10% carbonate still needs to be decomposed in the rotary kiln. It can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com