Process system for processing municipal domestic waste by cement rotary kiln

A technology of municipal solid waste and cement rotary kiln, which is applied in cement production and other directions to achieve the effect of large processing capacity, solving secondary pollution and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

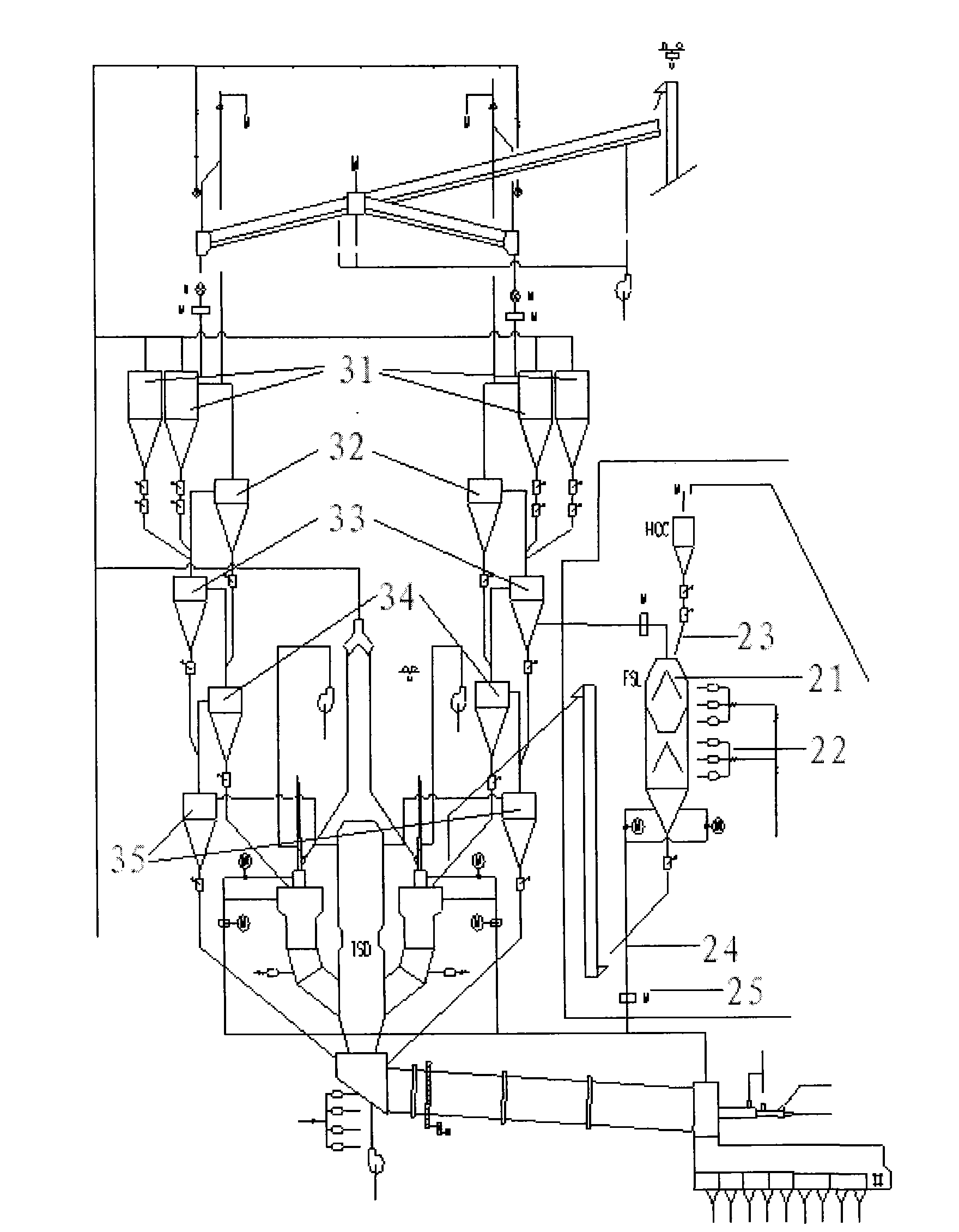

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, but not limited to the content listed in the embodiments.

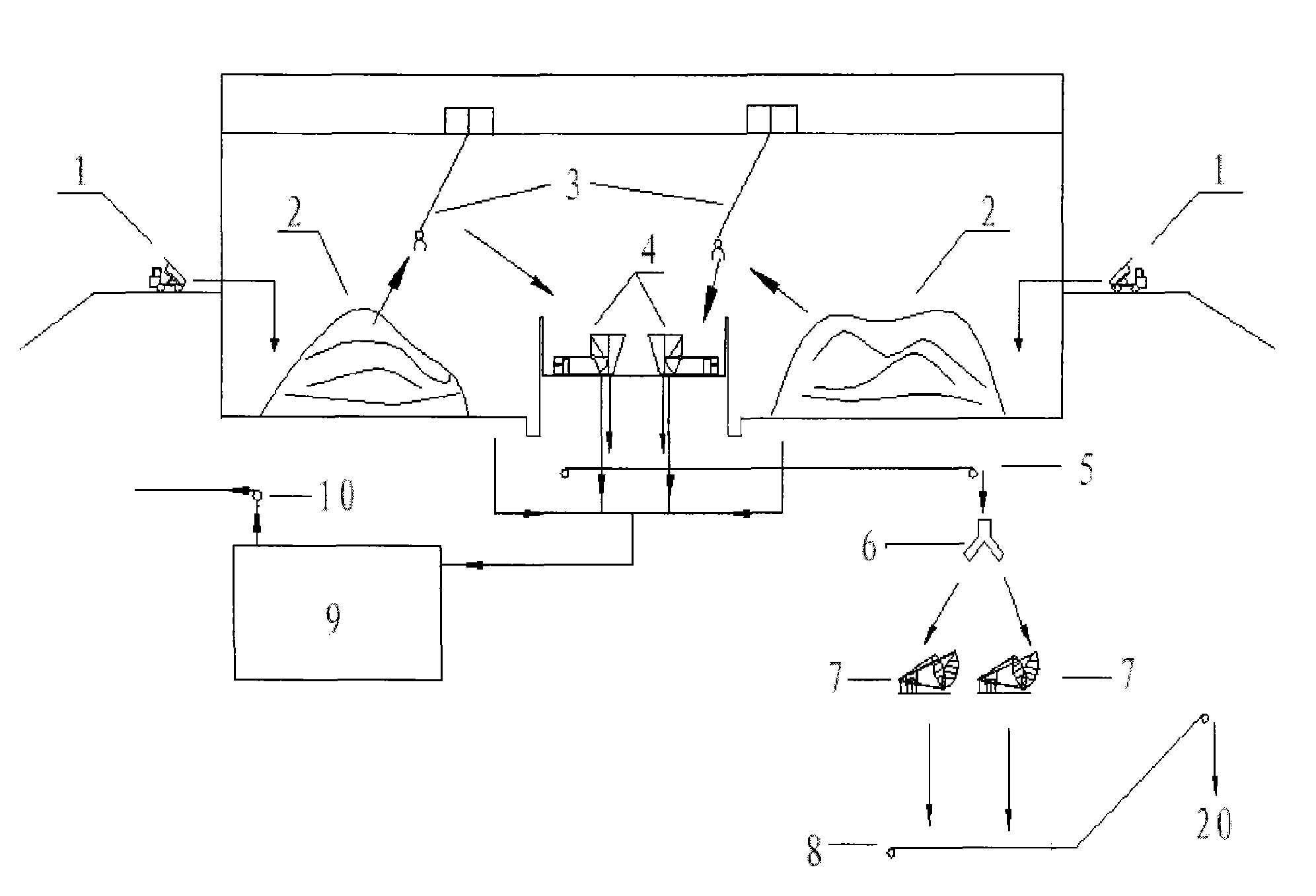

[0023] A cement rotary kiln process system of the present invention for treating municipal solid waste. In the manual sorting process, the dispersedly collected domestic solid waste is firstly transported to the transfer station, and the waste is manually sorted at the transfer station, and the large pieces of waste household appliances are sorted out. , furniture, concrete, iron and other metals and chlorine-containing PVC plastics, waste cables and other substances, and transport the sorted garbage to the cement plant with a garbage truck.

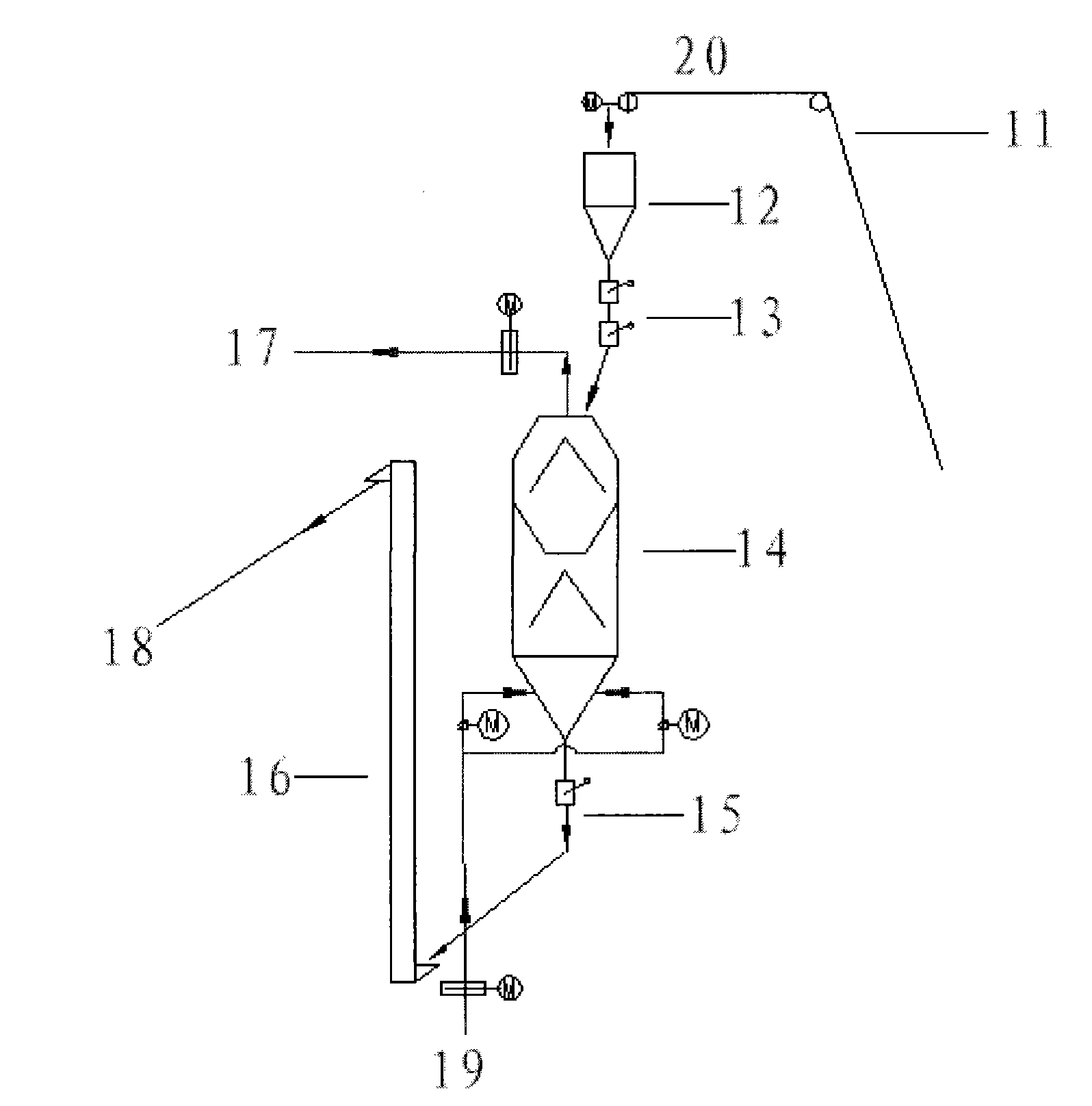

[0024] The sorted waste must first be dehydrated and crushed in the cement plant. Such as figure 1 As shown, after the garbage transport vehicle enters the factory, it first passes through the cement plant weighbridge for weighing. After weighing, the garb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com