Method for preparing an acceleration process of an internal combustion engine

A technology of internal combustion engine and rotational speed, applied in the direction of motor vehicles, mechanical equipment, engine control, etc., can solve problems such as hidden dangers of oncoming traffic safety, achieve the effect of avoiding delayed response characteristics and improving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

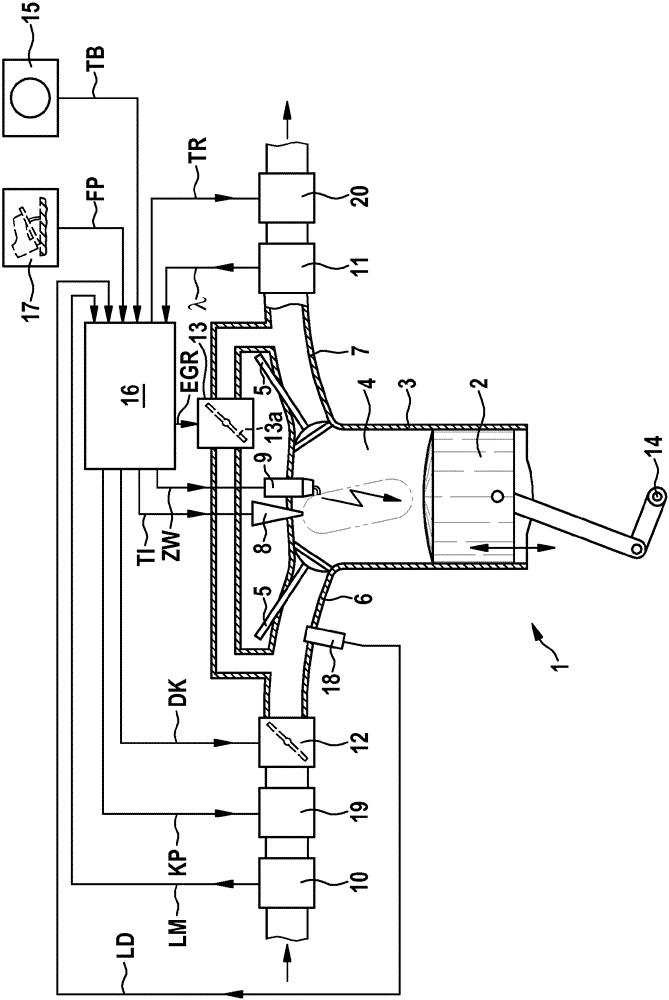

[0034] exist figure 1 shows an internal combustion engine 1 in which a piston 2 can move up and down in a cylinder 3 . The crankshaft 14 is set into a rotational movement by means of the pistons, through which at least one motor wheel is ultimately driven with a drive torque. For this purpose, the crankshaft is connected to a drive chain, which generally has a transmission, clutch, brake, electric motor, etc.

[0035] The cylinder 3 is equipped with a combustion chamber 4 on which an intake pipe 6 and an exhaust gas pipe 7 are connected via a valve 5 . The intake pipe 6 and the exhaust gas pipe 7 are connected through an exhaust gas return valve 13 having a valve flap 13a, which serves as an adjustment link for the return of exhaust gas to the outside. The valve flap 13 a can be controlled by a signal EGR from a controller (ECU) 16 . Furthermore, an injection valve 8 , which is controlled by the signal TI, and an ignition plug 9 , which is controlled by the signal ZW, are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com