Treatment method of acetic acid absorption tower wastewater

A treatment method and absorption tower technology are applied in the treatment field of acetic acid absorption tower wastewater, which can solve the problem of high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

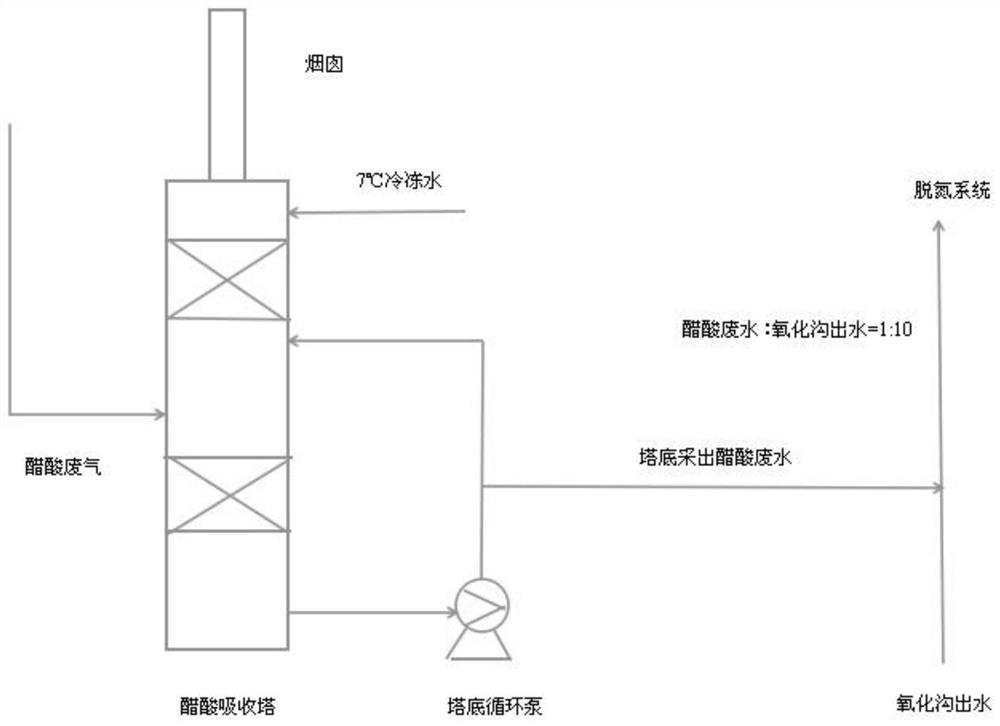

[0055] figure 1 It is a flow chart of the treatment method for the waste water of the acetic acid absorption tower in Example 1. The acetic acid waste gas is transported to the feed inlet at the bottom of the acetic acid absorption tower through pipelines, and 7°C frozen water enters from the acetic acid absorption tower. After the waste gas enters, it rises and falls. When the chilled water meets, the circulating pump at the bottom of the tower physically pumps a part of the bottom of the tower back to the top of the tower, and the other part (the acetic acid wastewater produced at the bottom of the tower) is mixed with the effluent of the oxidation ditch and enters the denitrification system for denitrification treatment. At the chimney of the acetic acid absorption tower Discharge insoluble and non-polluting gas.

[0056] At present, the denitrification system of the production process can treat 70m of alcohol wastewater 3 / h, and the use of carbon source pure ethanol 2Kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com