Hybrid modeling method for rotary cement kiln burning zone temperature based on LS_SVM soft measurement

A cement rotary kiln and firing zone technology, applied in character and pattern recognition, special data processing applications, instruments, etc., can solve the problem of inaccurate measurement of firing zone temperature, achieve real-time correction and avoid poor accuracy , the effect of good guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

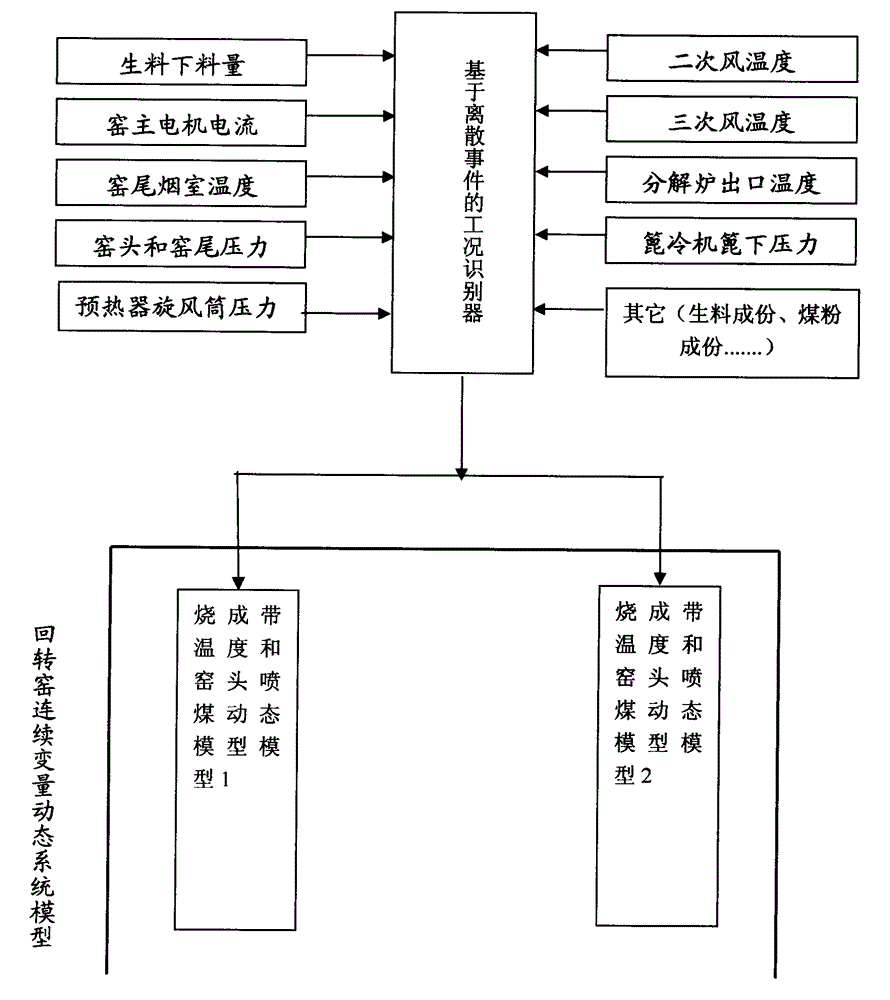

Method used

Image

Examples

Embodiment

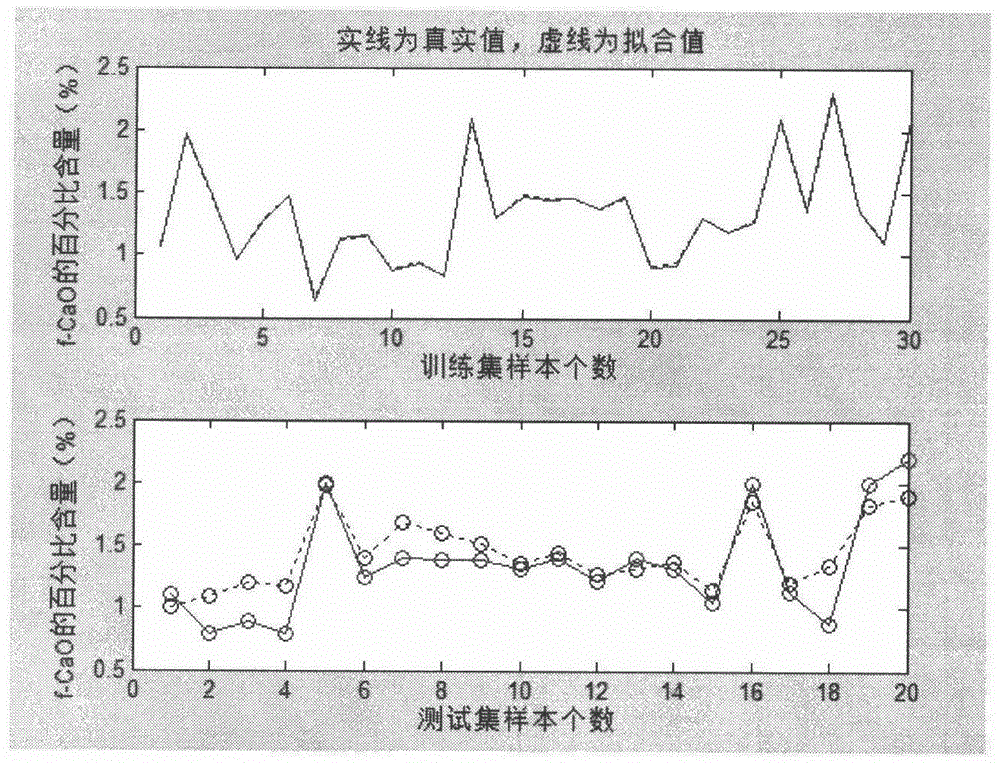

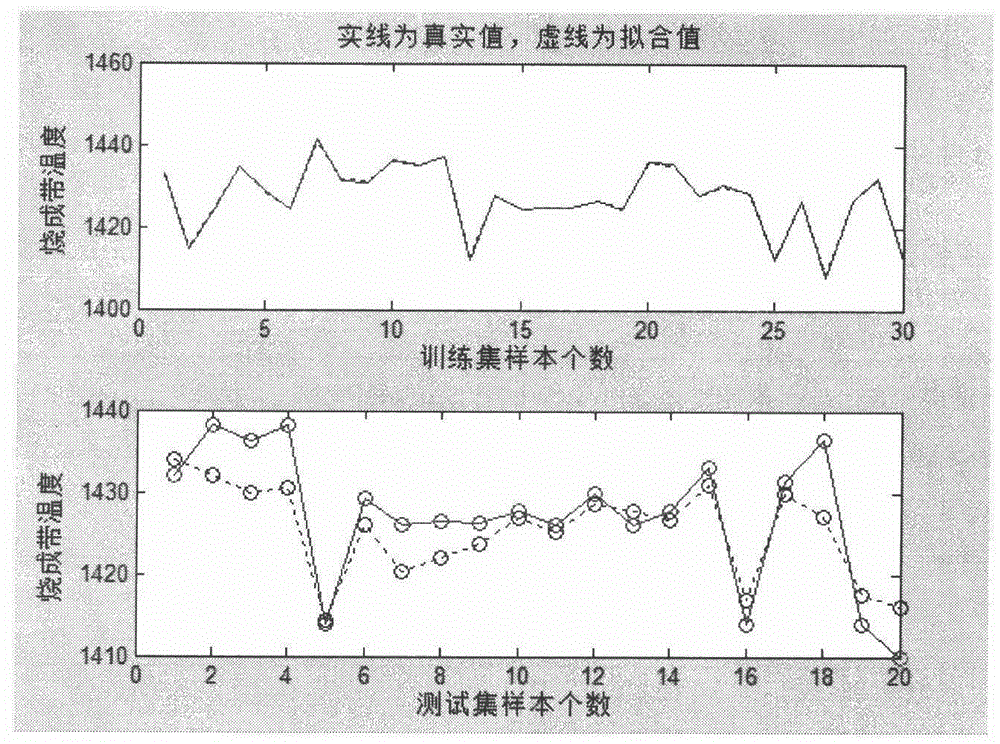

[0033] Firstly, the temperature change of the firing zone is modeled when the coal feed to the kiln head is 11.3t.

[0034] The accurate relationship between coal injection at the kiln head and the temperature of the firing zone can be obtained only when other factors affecting the temperature change of the firing zone are kept stable.

[0035] To ensure the stability of the amount of raw material feeding, the stable value is 133-137A; the outlet temperature of the calciner should also be stable at the benchmark value of 930, and the upper and lower lines are +-30; at the same time, it is necessary to ensure a stable amount of coal injection at the kiln head. The benchmark value is 11.3t; ensure that the grate cooler grate speed is stable between 10-15, so that the secondary air temperature will not be affected by the thickness of the material layer. At the same time, due to the large lag of the cement rotary kiln system, when selecting the variable value, it is necessary to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com