Cement rotary kiln and incinerator combined treatment system for urban domestic refuse

A technology of municipal solid waste and cement rotary kiln, which is applied in the field of recycling and harmless waste. It can solve the problems of difficult disposal of primary municipal solid waste, secondary pollution of water environment, and dissolution of heavy metal ions, so as to avoid energy conversion Loss, reduction of waste disposal costs, effects of less harmful gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in conjunction with the above drawings.

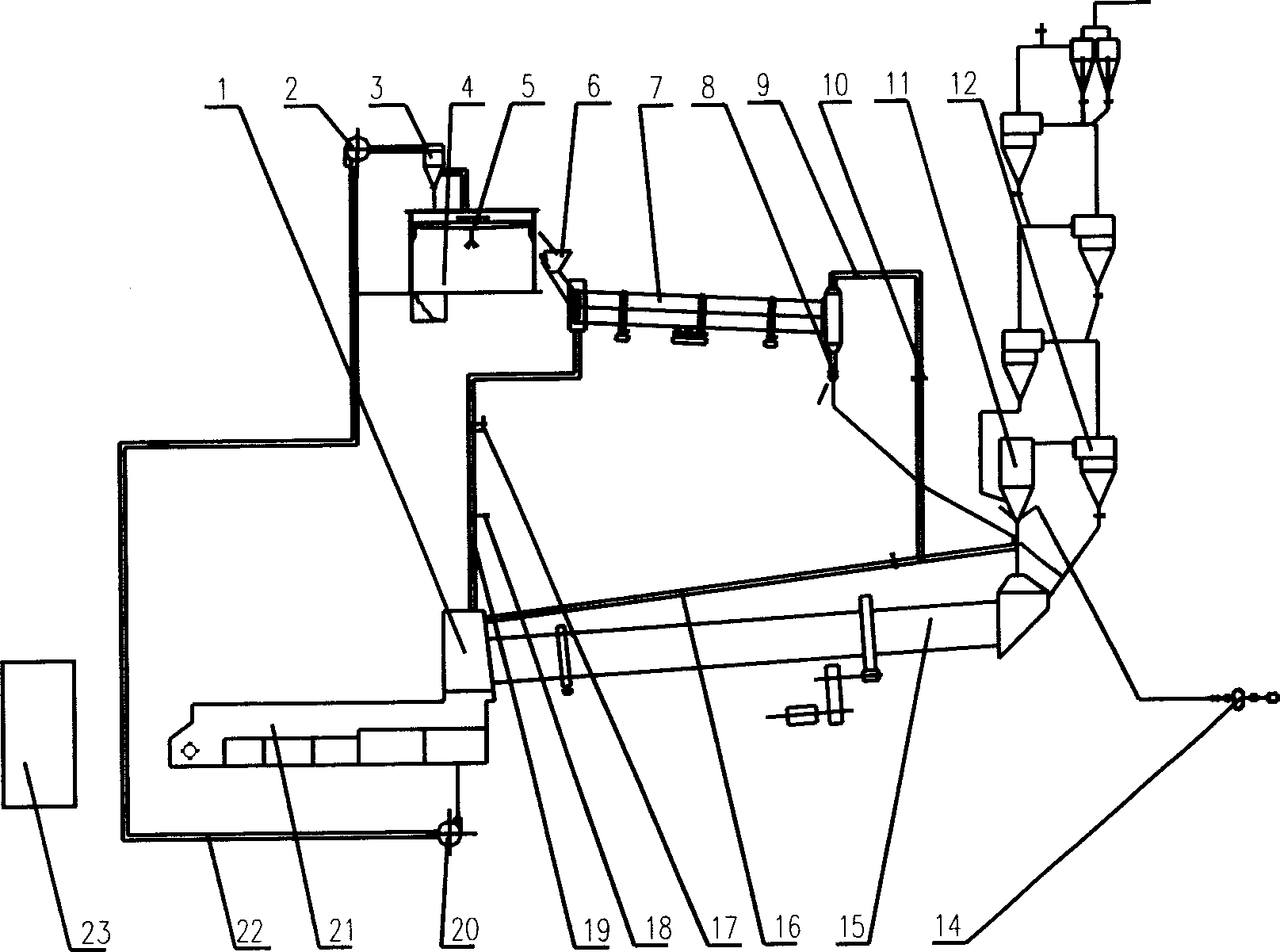

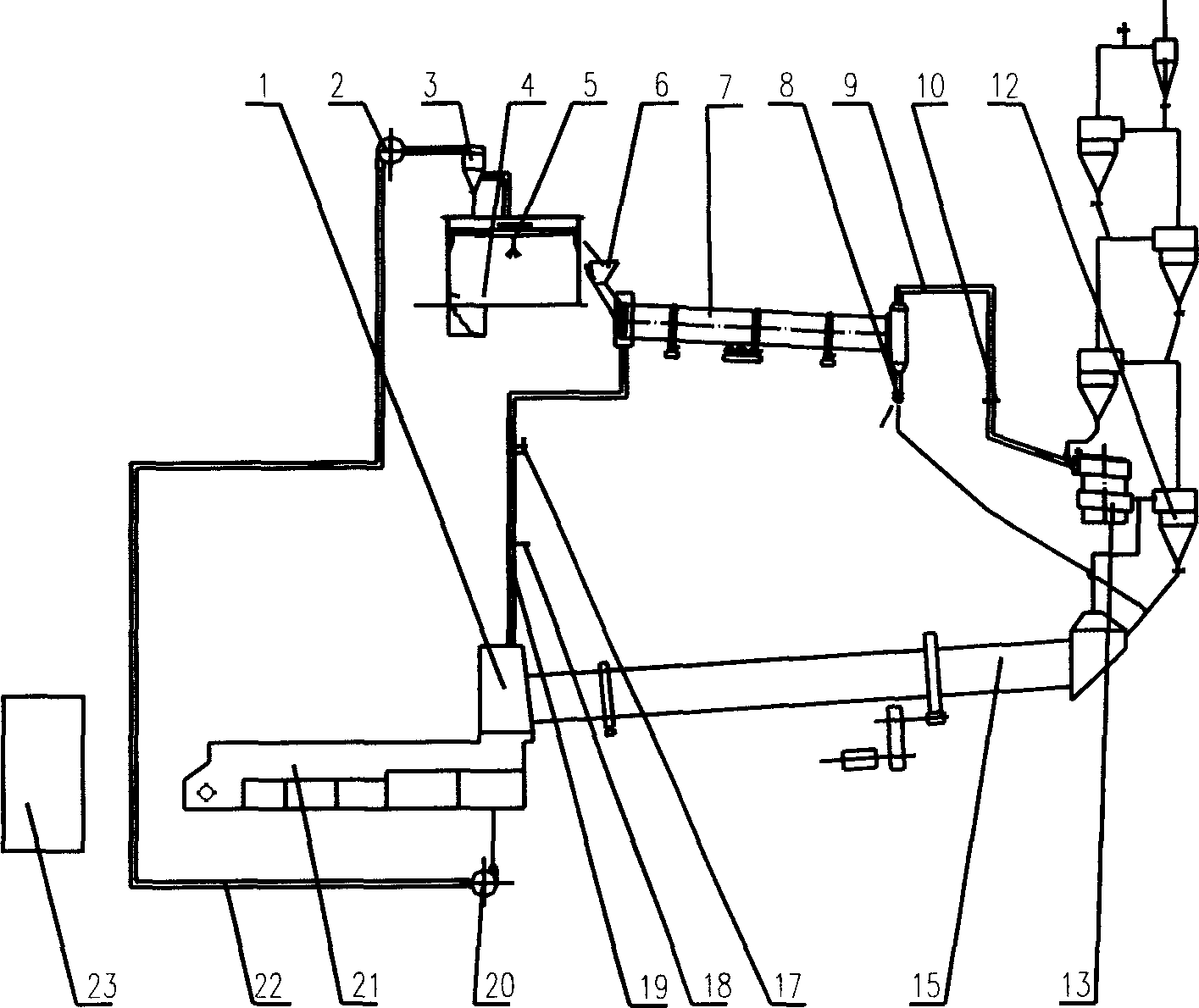

[0027] Such as figure 1 As shown, the municipal garbage truck transports the municipal garbage to the factory, and pours it into the garbage storage tank 4 by the garbage door of the garbage storage tank 4 after metering, and the garbage door is automatically closed after dumping. The unloaded garbage is observed by the operator through the large glass window outside the structure of the garbage storage pool 4, and the remote operation grabbing device 5 is sent to the small bin of the garbage feeder 6, and the garbage feeder 6 feeds the garbage into the rotary garbage incinerator7.

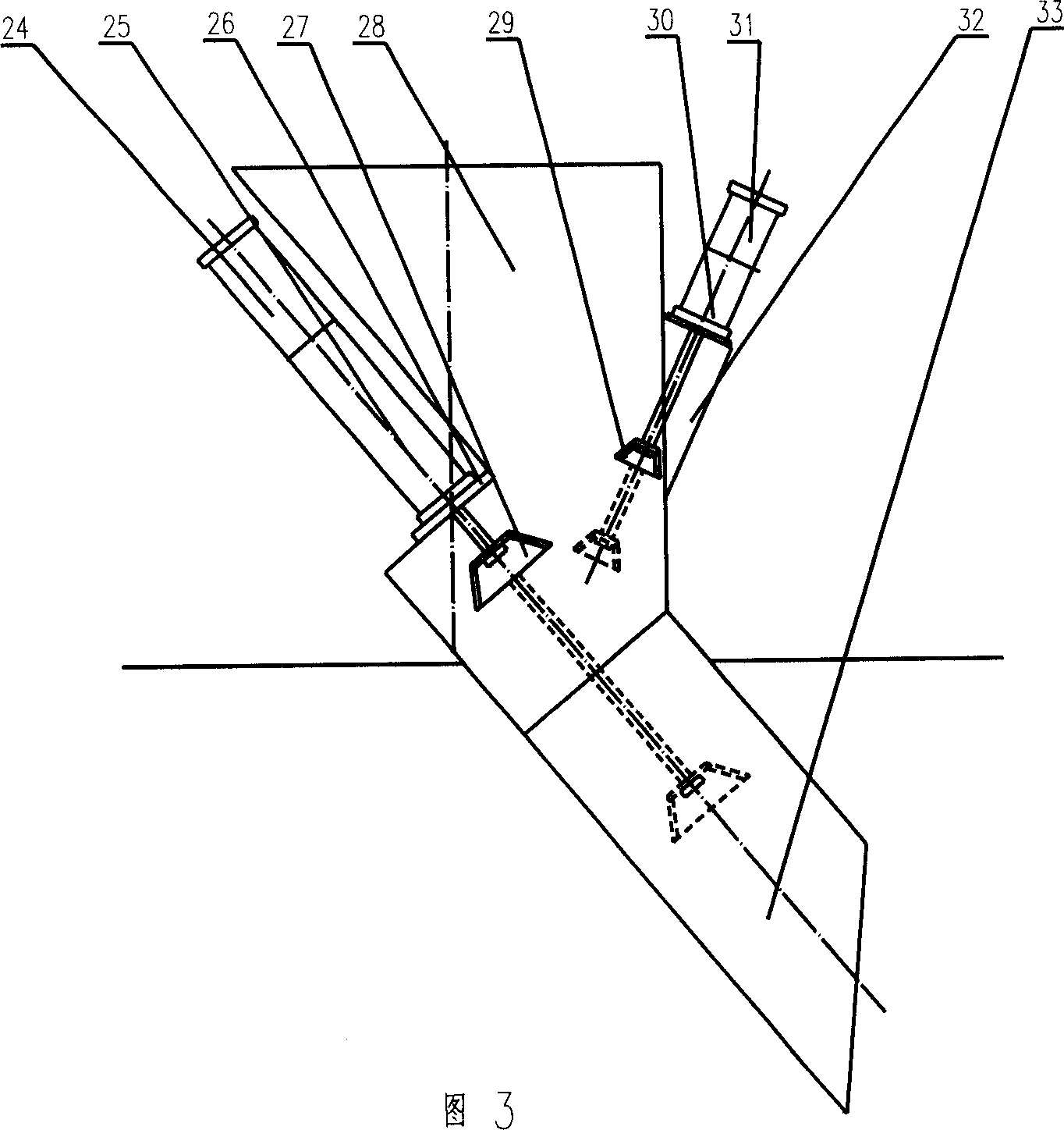

[0028] Experiments and theoretical analysis show that if the hot air from the cement clinker cooler is used as the air for incineration of waste, in order to make the incineration temperature reach 900°C, the low-level combustion calorific value of waste should exceed 4000kJ / kg. , it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com