Cement rotary kiln intelligent optimization control system

A cement rotary kiln, intelligent optimization technology, applied in the general control system, control/regulation system, program control and other directions, can solve the problem of frequent changes in operating conditions and working conditions, the detection of firing zone temperature and decomposition furnace temperature by noise interference, Big inertia and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] 1. The overall structure of the cement rotary kiln intelligent optimization control system

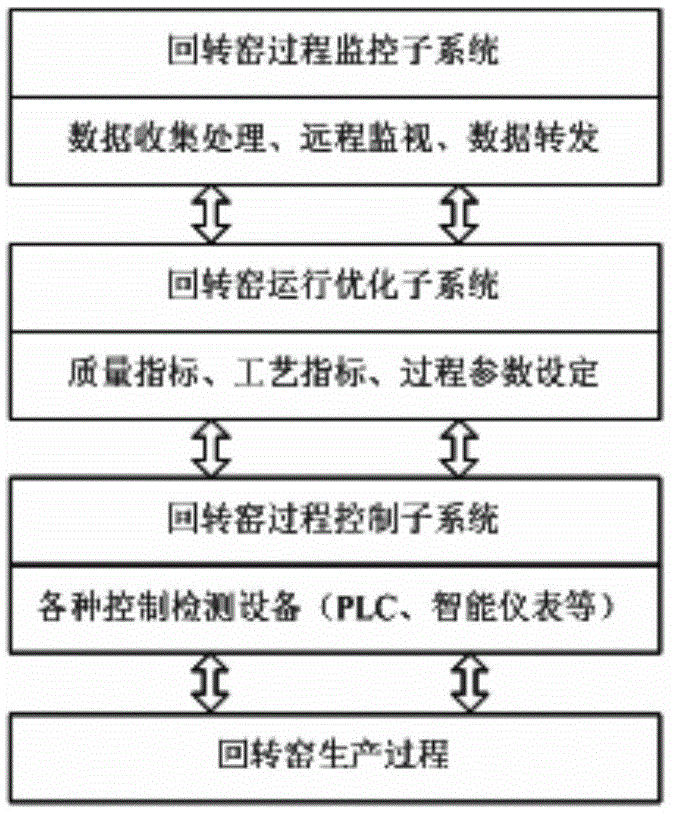

[0023] like figure 1 The structural diagram of the cement rotary kiln intelligent optimization control system shown:

[0024] The cement rotary kiln intelligent optimization control system is composed of the rotary kiln process control subsystem, the rotary kiln operation optimization subsystem and the rotary kiln process monitoring subsystem.

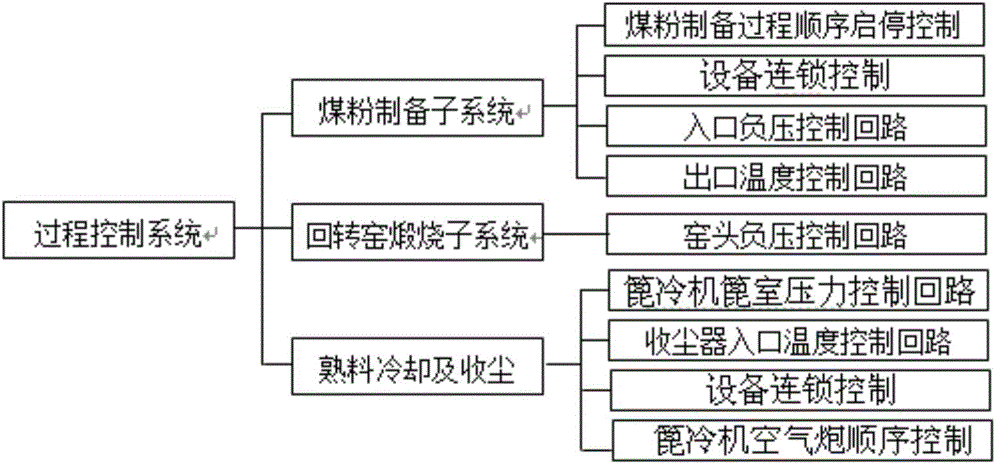

[0025] like figure 2 The structure diagram of the rotary kiln process control subsystem shown:

[0026] The rotary kiln process control subsystem consists of the rotary kiln head negative pressure control circuit, grate cooler grate chamber pressure control circuit, kiln head exhaust gas dust collector inlet temperature control circuit, coal powder preparation system inlet negative pressure control circuit, coal pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com