High-concentration saliferous organic waste liquid incinerator and incineration technique

A high-concentration salt-containing and organic waste liquid technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of short residence time of high-temperature flue gas, incomplete reaction of organic matter, large temperature difference, etc., and achieve long operation cycle , Excellent processing effect, large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

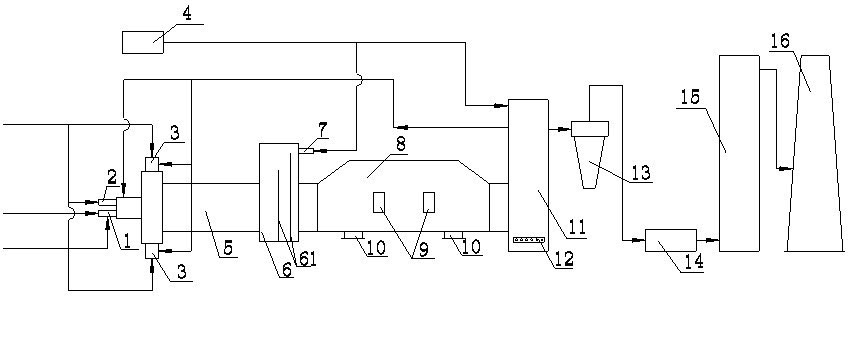

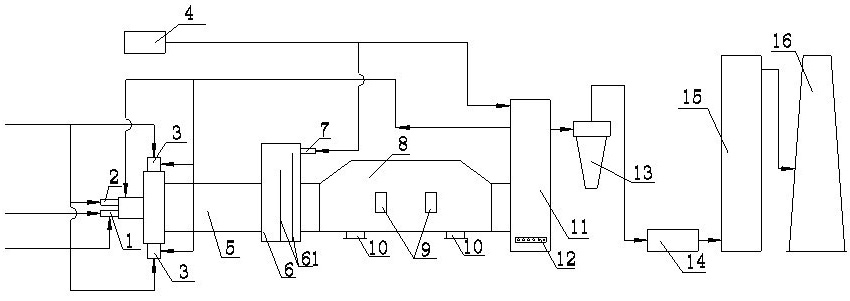

[0029] like figure 1 As shown, a high-concentration salt-containing organic waste liquid incineration device is provided with a horizontal furnace 5, a vertical furnace 6, a waste heat boiler 8, an air preheater 11, a cyclone separator 13, and an induced draft fan 14 in order according to the flow direction of the flue gas. , desulfurization tower 15 and chimney 16, the burner head of the horizontal furnace 5 is respectively provided with a waste liquid atomizing burner 1, an axial natural gas burner 2 and a tangential natural gas burner 3, and the waste liquid atomizing burner 1 is composed of compressed air. Atomization, the flue gas generated by the combustion of the axial natural gas burner 2 and the tangential natural gas burner 3 drives all the flue gas in the horizontal furnace 5 to make a swirling motion. The vertical furnace 6 is connected to the horizontal furnace 5, and a retaining wall 61 is arranged inside to make the flue gas deflected. At the rear of the retaini...

Embodiment 2

[0032] A high-concentration salt-containing organic waste liquid incineration process, comprising the following steps:

[0033] ①Turn on the blower 4 and the induced draft fan 14, put in the axial natural gas burner 2 and the tangential natural gas burner 3, so that the temperature of the incinerator reaches 1000 °C, and then put in the waste liquid burner 1, so that the temperature of the high-temperature combustion section of the horizontal furnace 5 reaches 1200℃.

[0034] ②Adjust the size of the cooling air system 7 of the vertical furnace 6 so that the temperature of the flue gas at the inlet 8 of the waste heat boiler is 1050°C.

[0035] ③ After the flue gas passes through the waste heat boiler 8 and the air preheater 11, the temperature drops to 260°C, and the temperature of the preheated air rises to 280°C, and the purging system 12 of the air preheater 11 is turned on to preheat the air. The flue gas pressure at the inlet of the device 11 is maintained below 2000Pa. ...

Embodiment 3

[0039] A high-concentration salt-containing organic waste liquid incineration process, comprising the following steps:

[0040] ①Turn on the blower 4 and the induced draft fan 14, put in the axial natural gas burner 2 and the tangential natural gas burner 3, so that the temperature of the incinerator reaches 1000 °C, and then put in the waste liquid burner 1, so that the temperature of the high-temperature combustion section of the horizontal furnace 5 reaches 1280℃.

[0041] ② Adjust the size of the cooling air system 7 of the vertical furnace 6 so that the temperature of the flue gas at the inlet 8 of the waste heat boiler is 1050°C.

[0042]③ After the flue gas passes through the waste heat boiler 8 and the air preheater 11, the temperature drops to 290°C, and the temperature of the preheated air rises to 300°C, and the purging system 12 of the air preheater 11 is turned on to preheat the air. The flue gas pressure at the inlet of the device 11 is maintained below 2000Pa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com