Method of preparing hydrogen by reforming methanol-water steam

A steam reforming and methanol technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of unresolved reaction heat supply, pollution, inability to meet mobile hydrogen production, and large device volume. Achieve the effect of mobile on-site hydrogen production, easy mobile on-site hydrogen production, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

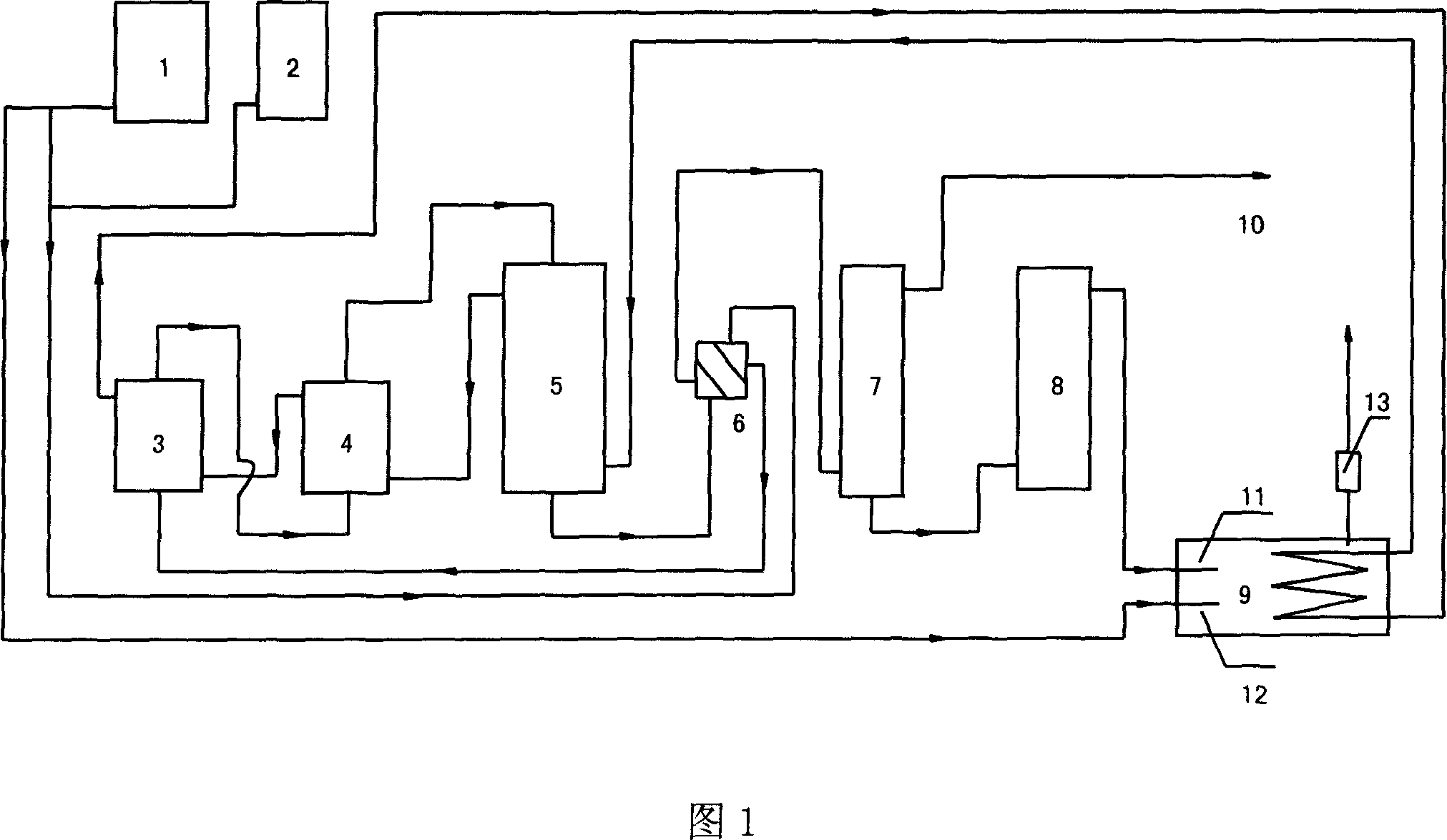

[0028] The process flow of the method for preparing hydrogen by steam reforming of methanol in this embodiment is as shown in Figure 1, and the method is as follows:

[0029] The raw material methanol 1 and soft water 2 are passed into the device at a molar ratio of 1:1.6, preheated to 90°C through the heat exchanger 6, vaporized in the vaporizer 3, and then overheated in the superheater 4 to reach a reaction temperature of 230°C. The reforming reaction is carried out in the device 5, using CuO / ZnO / Al 2 o 3 Catalyst, the reaction pressure is 0.85Mpa, the gas after the reaction is heat-exchanged by the heat exchanger 6 to obtain a reformed mixed gas; the reformed mixed gas enters the pressure swing adsorption system 7 for purification and separation, and two parts of the product hydrogen 10 and the purge gas are obtained;

[0030] In the hydrogen production process of methanol steam reforming in this embodiment, the three steps of vaporization, superheating and reforming react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com