Modular electronic-controlled engine model

An electronically controlled engine and engine technology, applied in the field of teaching aids, can solve the problems of complex parts, bulky, inconvenient disassembly, and assembly, and achieve the effects of easy understanding, improved interchangeability, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

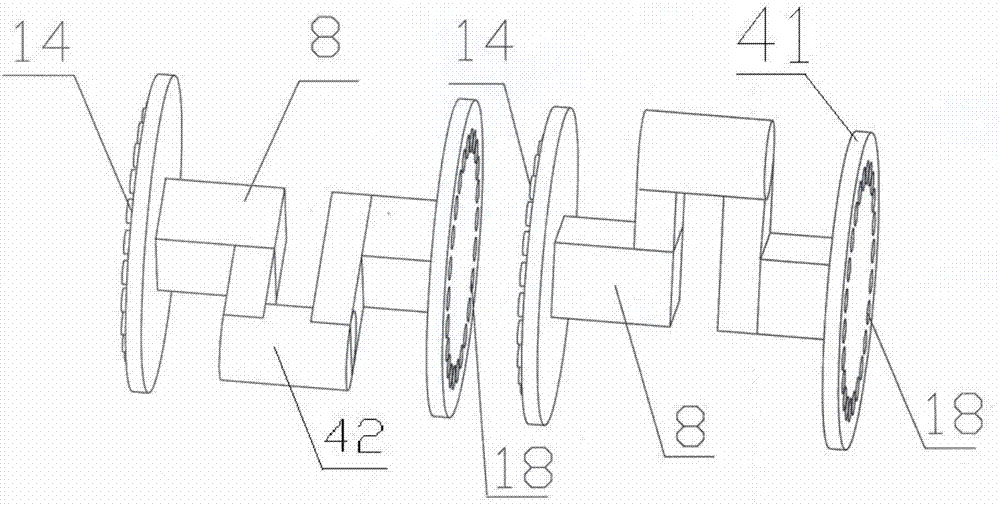

[0018] The modular electronically controlled engine model of the present invention is further described by taking the technical solutions of a 6-cylinder in-line engine model, an 8-cylinder V-shaped engine model, and a 4-cylinder opposed engine model as examples.

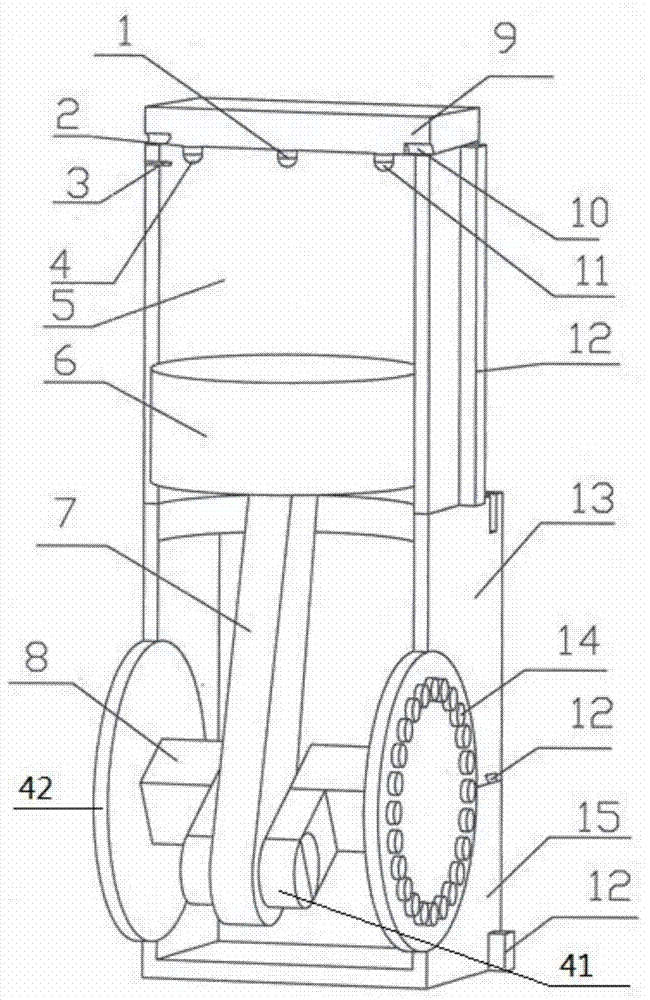

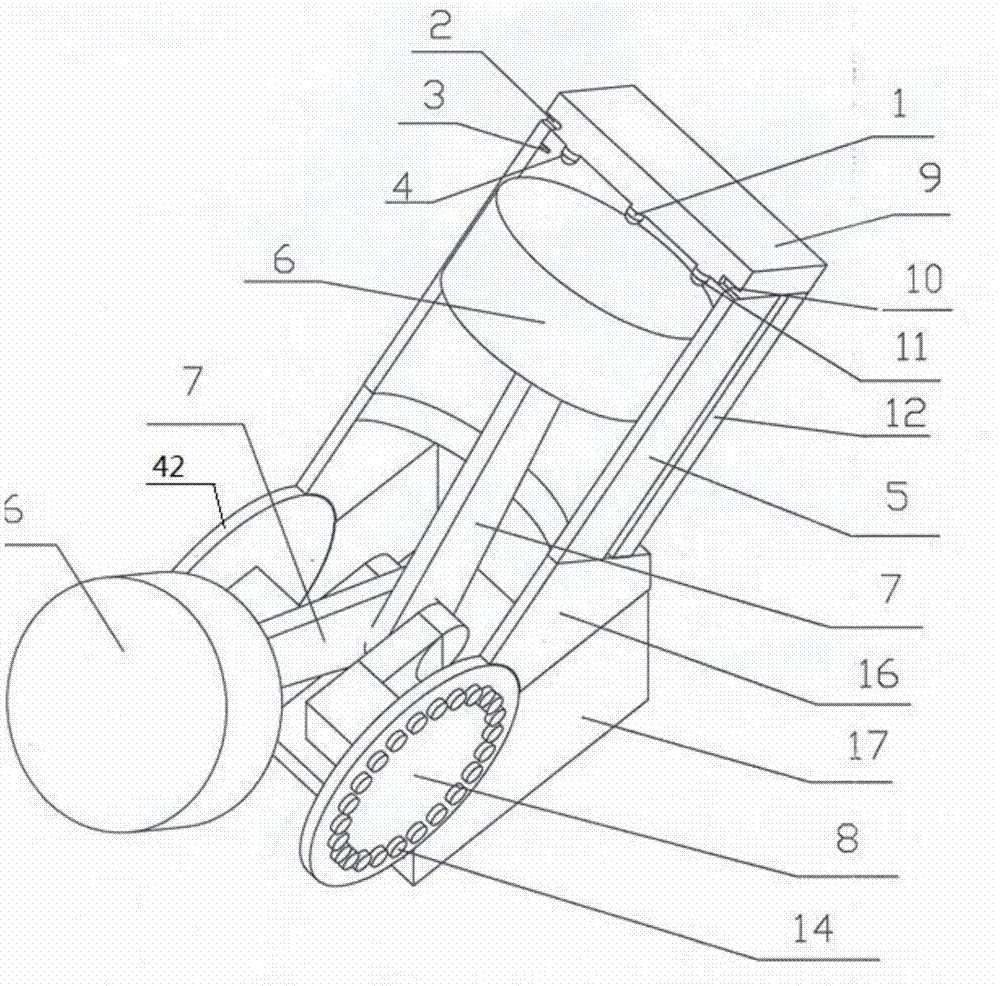

[0019] Such as figure 1 As shown, the in-line and opposed single-cylinder engine model structures of the present invention are composed of ignition LED lamp 1, intake valve 2, position sensor 3, intake LED lamp 4, cylinder 5, piston 6, connecting rod 7. Crank throw 8, cylinder head 9, exhaust valve 10, exhaust LED lamp 11, dovetail groove structure 12, crankcase upper case 13, crank throw 8 connecting boss 14 and crankcase lower case 15. The cylinder head 9 is fixed on the cylinder 5 through the dovetail groove structure 12, the ignition LED light 1 is located in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com