Testing method and device of single cylinder engine simulation complete machine

A test method and technology of a test device, applied in the direction of internal combustion engine testing, etc., can solve problems such as large errors, achieve the effects of improving accuracy, reducing the test workload of the whole machine, and improving R&D efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

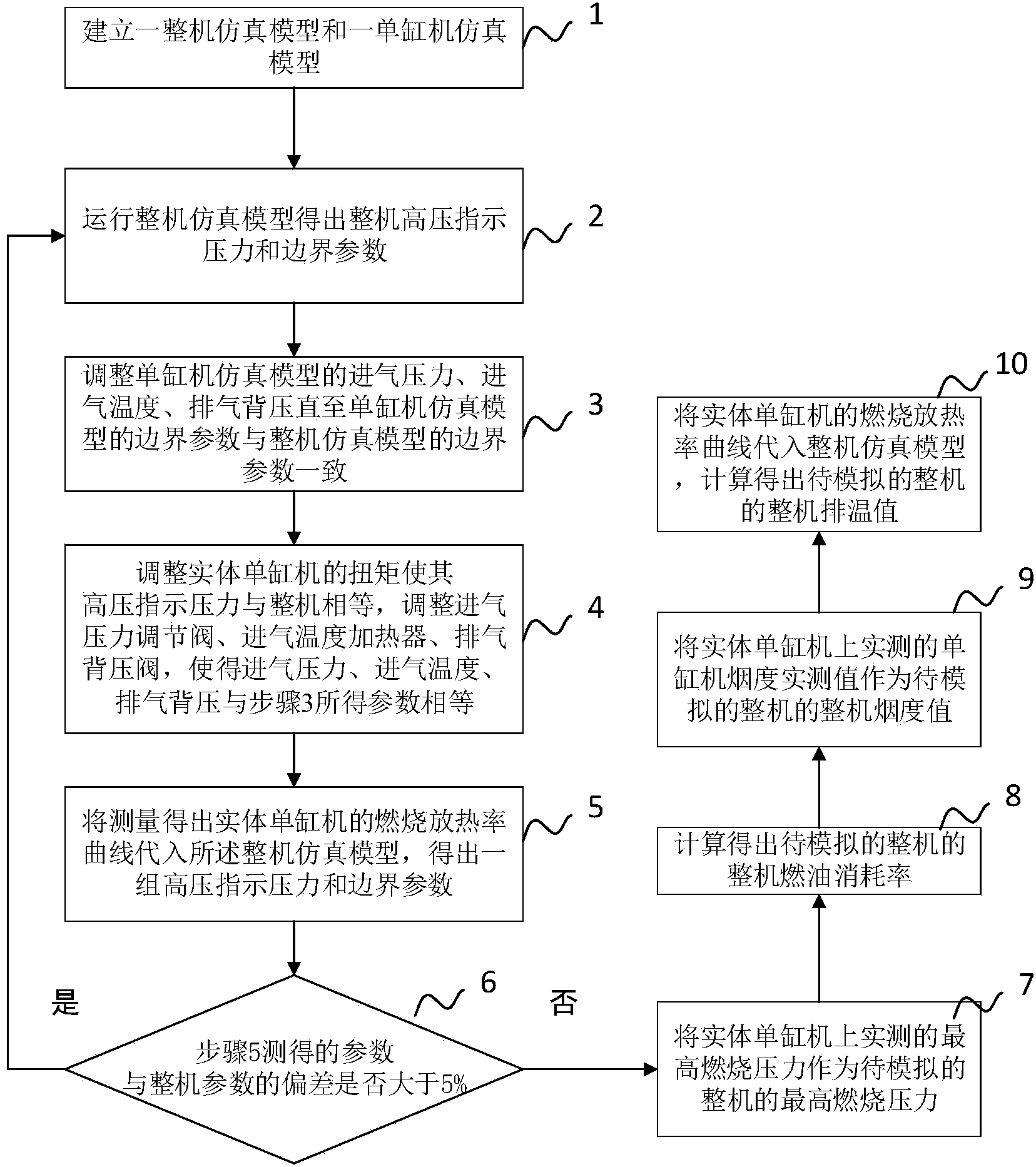

[0044] figure 1 For the flow chart of the test method of the single-cylinder machine simulation complete machine of the present embodiment, as figure 1 As shown, the test method of the single-cylinder machine simulation complete machine involved in this embodiment includes the following steps:

[0045] Step 1. Establish a complete machine simulation model and a single-cylinder machine simulation model.

[0046] Step 2. Run the whole machine simulation model to obtain the whole machine high pressure indication pressure and boundary parameters, wherein, the whole machine high pressure indication pressure is the average indicated pressure of the gas in the cylinder at the compression and expansion nodes of the whole machine simulation model, and the boundary parameters include single cylinder The intake air volume in the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com