Fuel injecting electronic unit pump of single-cylinder diesel engine

A diesel engine and fuel injection technology, applied in engine components, machines/engines, fuel injection devices, etc., can solve the problem that it is difficult for high-pressure fuel injection pumps to meet the emission standards of non-road national III and above, and the electronically controlled unit pumps for vehicles cannot. Direct application, control accuracy, low control flexibility, etc., to achieve the effect of improving economy and operability, small changes in overall structure, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

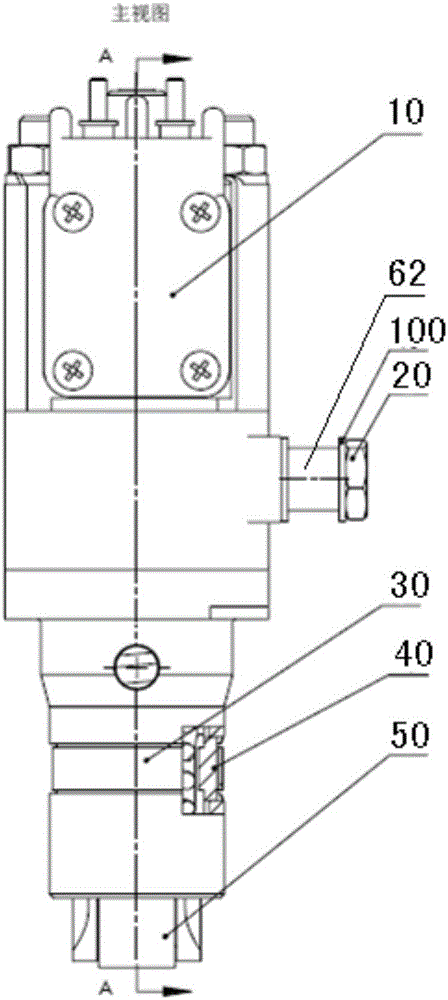

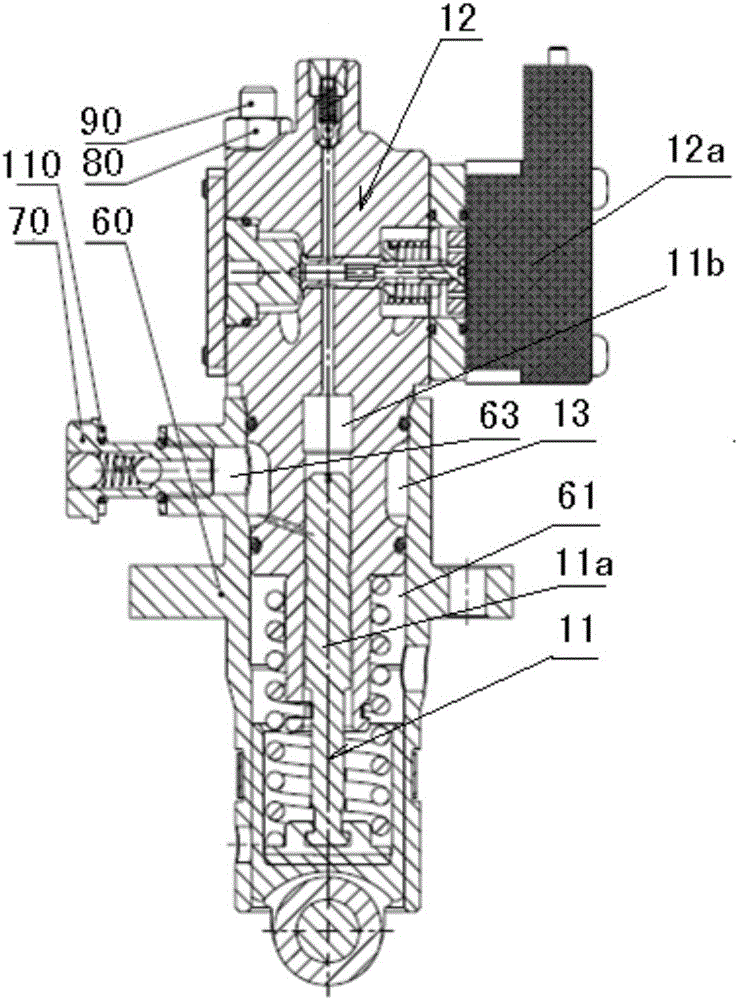

[0021] See figure 1 with figure 2 , The single-cylinder diesel engine electronically controlled fuel injection unit pump shown in the figure can be directly inserted into the single-cylinder engine block and directly installed on the single-cylinder engine block gear chamber cover, driven by the oil pump camshaft to supply fuel, Without major changes, the emission level of the existing diesel engine using mechanical inline pumps will be upgraded from non-road country II to non-road country III and above.

[0022] The single-cylinder diesel engine electronically controlled fuel injection unit pump includes a guide sleeve 60. An axial electronically controlled pump component mounting hole 61 is provided in the guide sleeve 60. The top of the electronically controlled pump component mounting hole 61 is open, and the guide sleeve The upper part of the sleeve wall 60 is provided with an oil inlet 62 and a pressure-regulating hole 63, and the lower part of the guide sleeve 60 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com