Piston top dead center automatic detecting and positioning device of reciprocating machinery

A technology of automatic detection and positioning device, applied in measuring devices, instruments, etc., can solve the problems of unguaranteed piston installation accuracy and the influence of engine compression ratio, and achieve the effects of short response time, improved accuracy and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

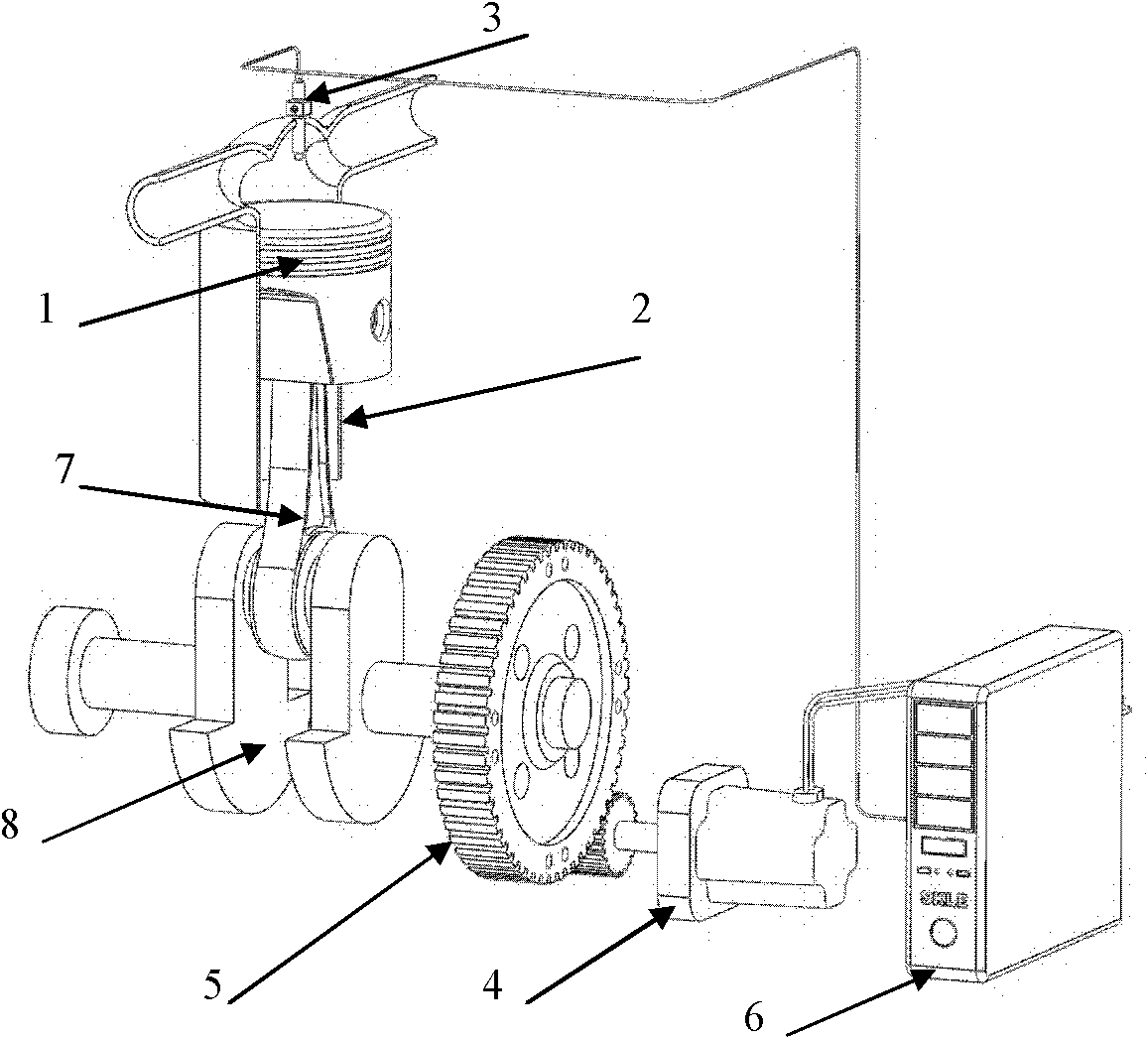

[0008] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. The reciprocating mechanical piston top dead center automatic detection and positioning device includes: piston, cylinder liner, displacement sensor, stepper motor, flywheel ring gear, computer, connecting rod and crankshaft, etc. (such as figure 1 As shown), the system structure is that a displacement sensor 3 is installed at the position of the fuel injection nozzle in the cylinder liner 2 above the piston 1, the gear of the stepping motor 4 meshes with the flywheel ring gear 5 of the engine, and the signal output of the displacement sensor is connected to The input end of the controller 6, the driving power line of the stepping motor 4 is connected to the output end of the controller 6.

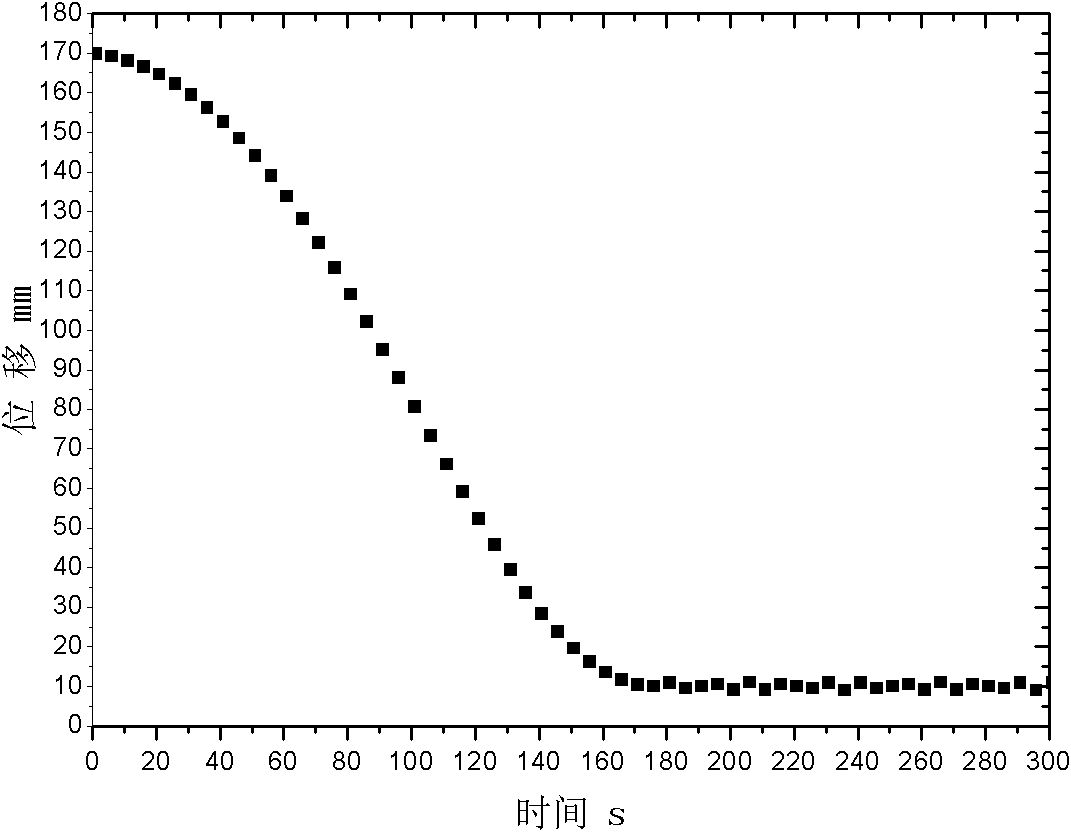

[0009] In order to verify the implementation effect of the present invention, the engine single-cylinder machine test is adopted, the displacement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com