System and method for collecting combustion products of constant volume combustion bomb

A technology of constant volume incendiary bombs and combustion products, used in chemical analysis, instruments, analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

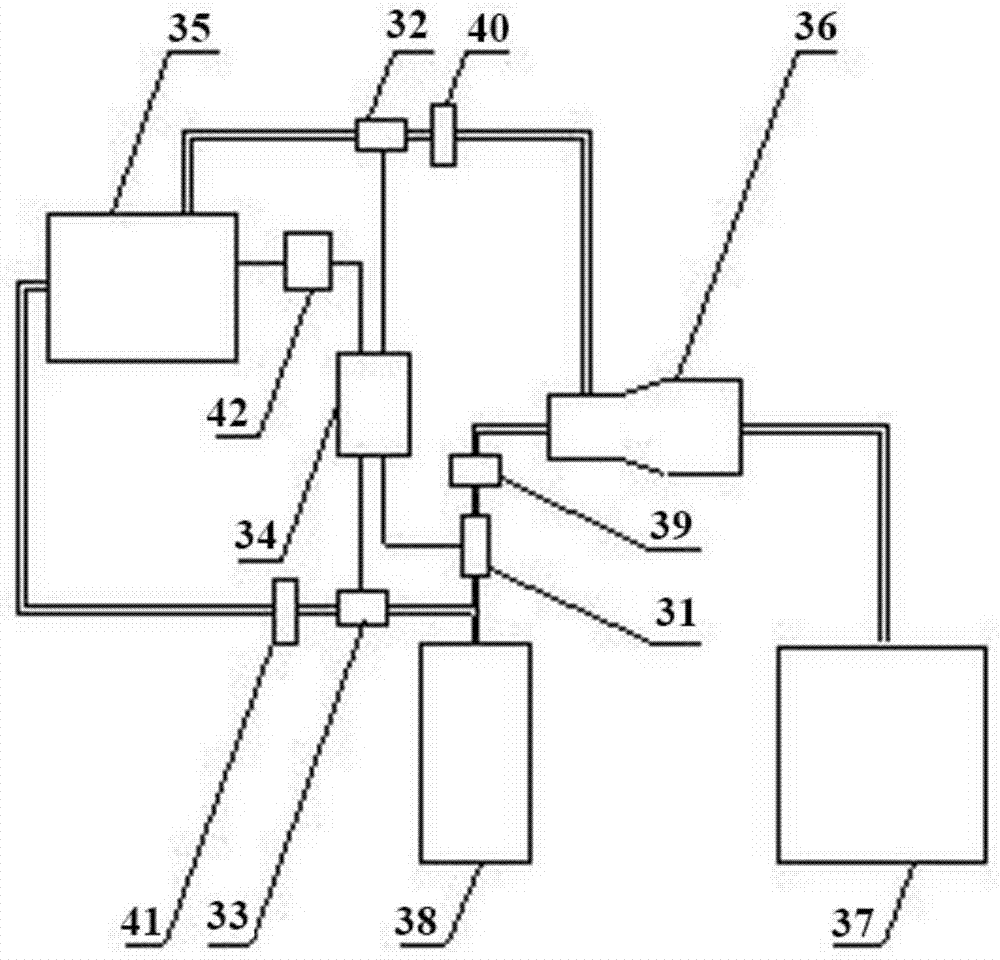

[0050] Constant volume combustion bomb combustion product collection system, including:

[0051] Constant-volume combustion bomb 35 is used to simulate fuel combustion, including intake and exhaust systems, heating systems, and fuel supply systems; the combustion products of constant-volume combustion bombs are driven by high-pressure nitrogen and pass through the second solenoid valve and the second flow rate in sequence Valve, the combustion product inlet into the quenching device;

[0052] Quenching device 36;

[0053] The first solenoid valve 31 and the first flow metering valve 39 are installed between the nitrogen cylinder and the quenching device; the second solenoid valve 32 is a high temperature solenoid valve; the second flow metering valve 40 is installed in a constant volume. Between the combustion bomb and the quenching device; the third solenoid valve 33 is a high-pressure solenoid valve; the third flow metering valve 41; the two are installed between the nitrogen cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com