System and method for measuring spray micro-characteristics in constant-volume combustion device

A technology of constant volume combustion and measurement system, applied in measurement devices, instruments, particle size analysis and other directions, can solve the problems of advanced optical measurement instrument coordination, research, hindering the depth of fuel crushing and atomization, etc., to improve the accuracy of data collection and experimental results , Realize the effect of real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

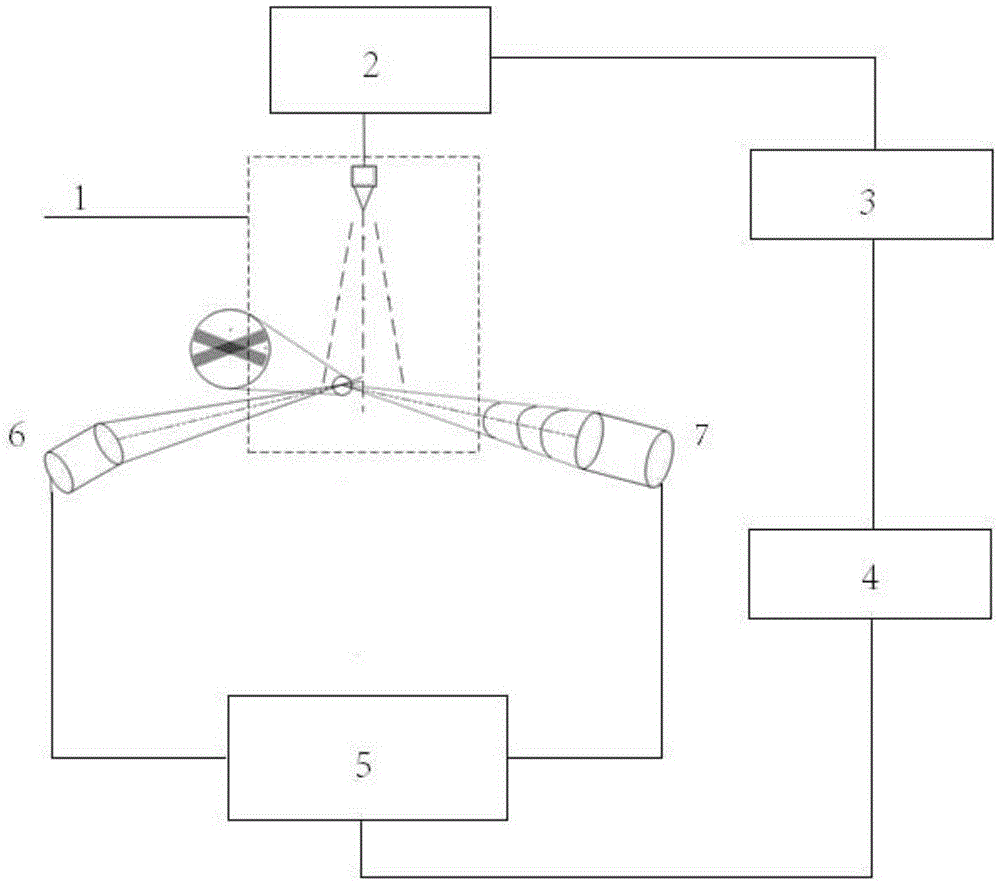

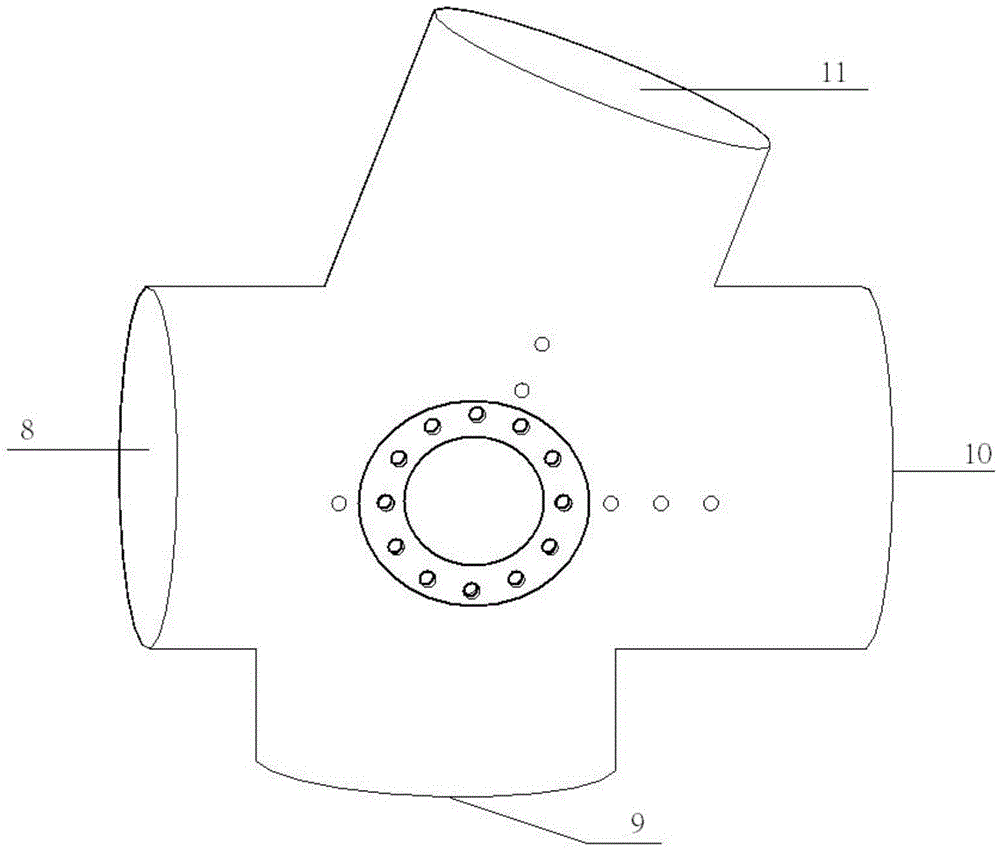

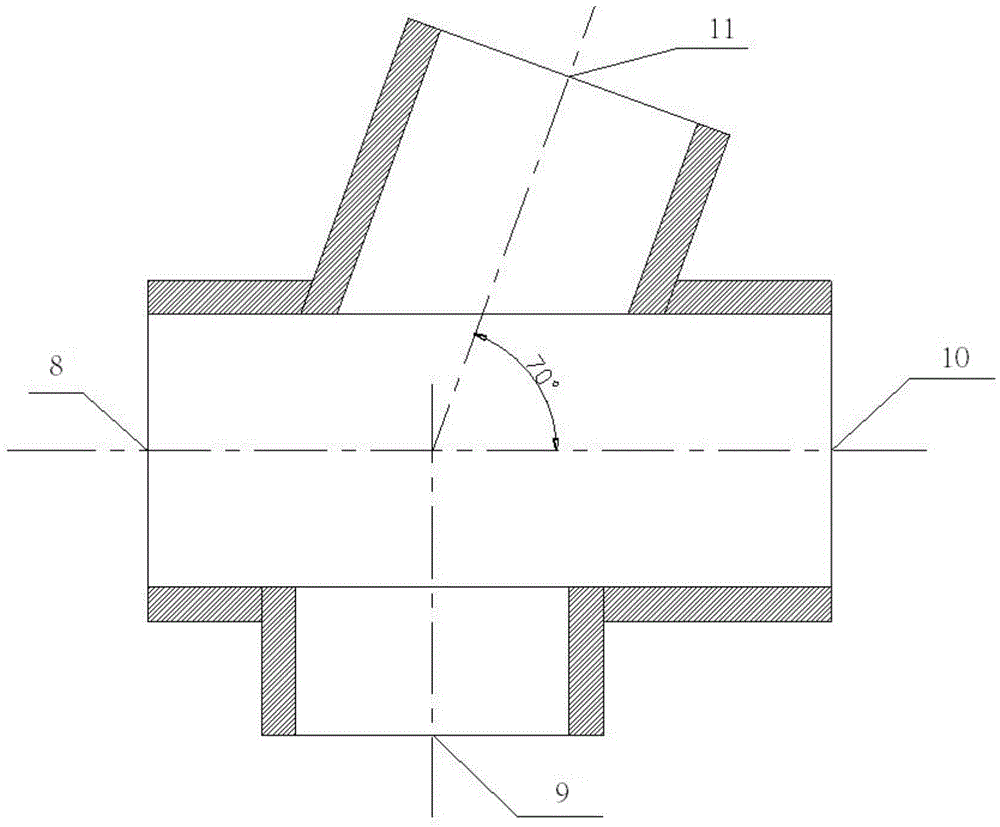

[0028] Such as figure 1 and figure 2 As shown, a measurement system for spray microscopic characteristics of a constant volume combustion device includes a constant volume combustion device 1, a fuel supply system 2 with a controller 3, a digital delay generator 4 and a phase Doppler particle analyzer 5 ( PDA), the phase Doppler particle analyzer 5 (PDA) has a transmitting probe 6 and a receiving probe 7, and the constant volume combustion device 1 includes a combustion bomb installed inside the box, between the box and the combustion bomb The space is filled with asbestos for heat preservation. The incendiary bomb body is provided with four observation holes in the shape of through holes. The axes of the observation holes are all on the same horizontal plane, and the angle between the axes of the two observation holes is 180°. , the angle between the axes of the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com