Roller side movement cylindrical cam single-cylinder engine

A cylindrical cam and engine technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of large volume, sudden change in speed, etc., and achieve the effects of prolonging life, reducing volume, and good hybrid expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

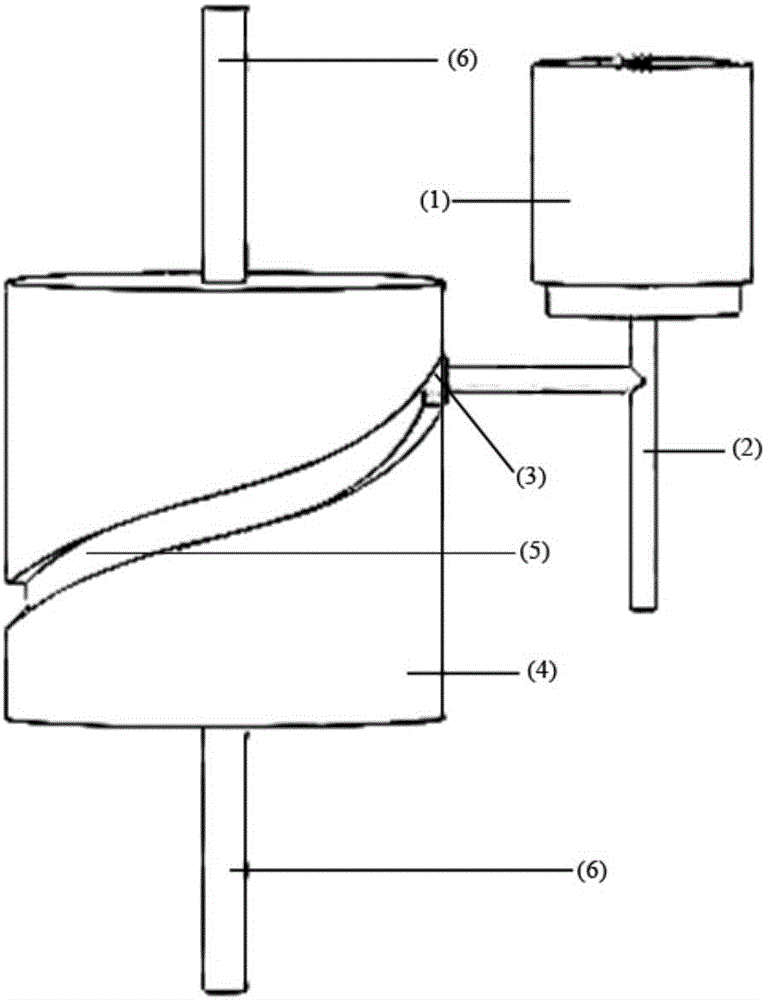

[0014] The invention provides a roller side-moving cylindrical cam single-cylinder engine, which includes a piston 1 connected with a push rod 2, and a cylindrical cam 4 (cam rotor). A power shaft 6 is fixed on the cylindrical cam 4, and the outer side of the cylindrical cam 4 is A cam chute 5 is provided; the push rod 2 side of the piston 1 is provided with a side rod with a roller 3 at the top, and the push rod 2 is placed next to the cylindrical cam 4, and the push rod 2 is always in line with the cylindrical cam when it moves linearly. 4 The relative position remains unchanged. The roller 3 moves in the cam slideway 5, and the linear reciprocating motion of the piston push rod 2 is converted into a rotary motion through the cylindrical cam 4. Both ends of the cylindrical cam 4 are respectively fixed with power shafts 6 .

[0015] The cam sliding groove 5 is a cosine curve.

[0016] exist figure 1 In the process, the piston 1 pushes the push rod 2 for linear motion. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com