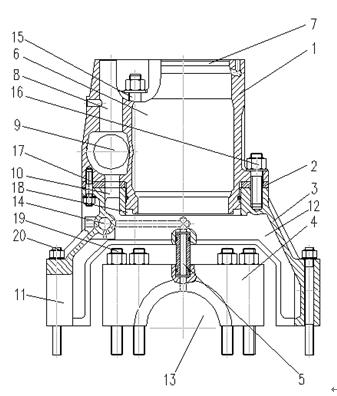

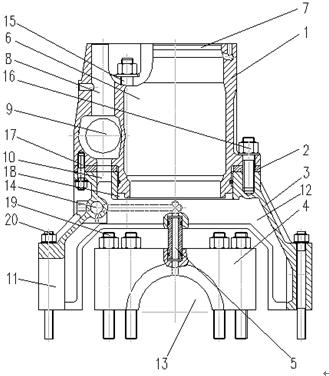

Adjustable single cylinder engine body structure

A single-cylinder machine, adjustable technology, applied in the direction of machine/engine, cylinder, cylinder head, etc., can solve the problems of narrow application range, low degree of specialization, and disorderly arrangement of oil passages of the body, and achieve convenient model performance. Research, improve the degree of integration, and apply to a wide range of models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation

[0011] An adjustable single-cylinder machine body structure, which includes a cylinder block, an adjustment plate, a crankcase, an upper bearing cover, and an oil filter. A cylinder hole is arranged in the cylinder body, and a matching hole is arranged on the left side of the cylinder block from top to bottom Air lifter holes, camshaft support holes, air distribution and oil return holes, the crankcase is arranged at the lower part of the cylinder block, and is positioned through the cylinder block positioning spigot hole, and the adjustment plate is arranged between the cylinder block and the crankcase, and the crankshaft The lower part of the box is provided with a connecting rod disassembly hole, and the crankcase is longitudinally provided with the first arched partition, the second arched partition, the third arched partition, the first arched partition, and the second arched partition , the third arched partition is configured correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com