Fue supply structure for small vehicle engine

A fuel supply and engine technology, which is applied to the layout, engine components, engine control, etc. combined with the fuel supply of an internal combustion engine, can solve the problem of difficulty in ensuring the installation reliability of the fuel injection valve fuel pipe, and achieve the effect of improving the installation reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

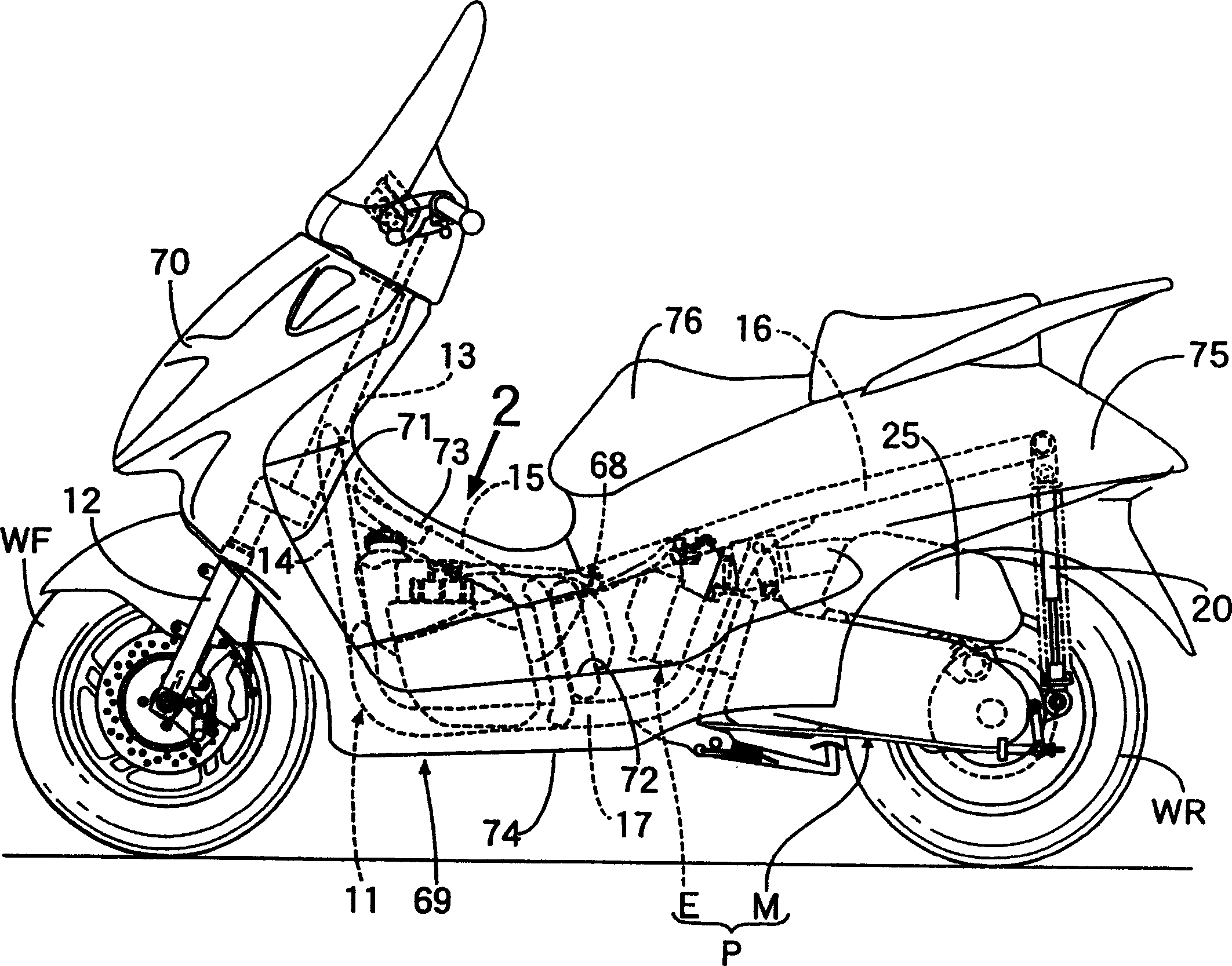

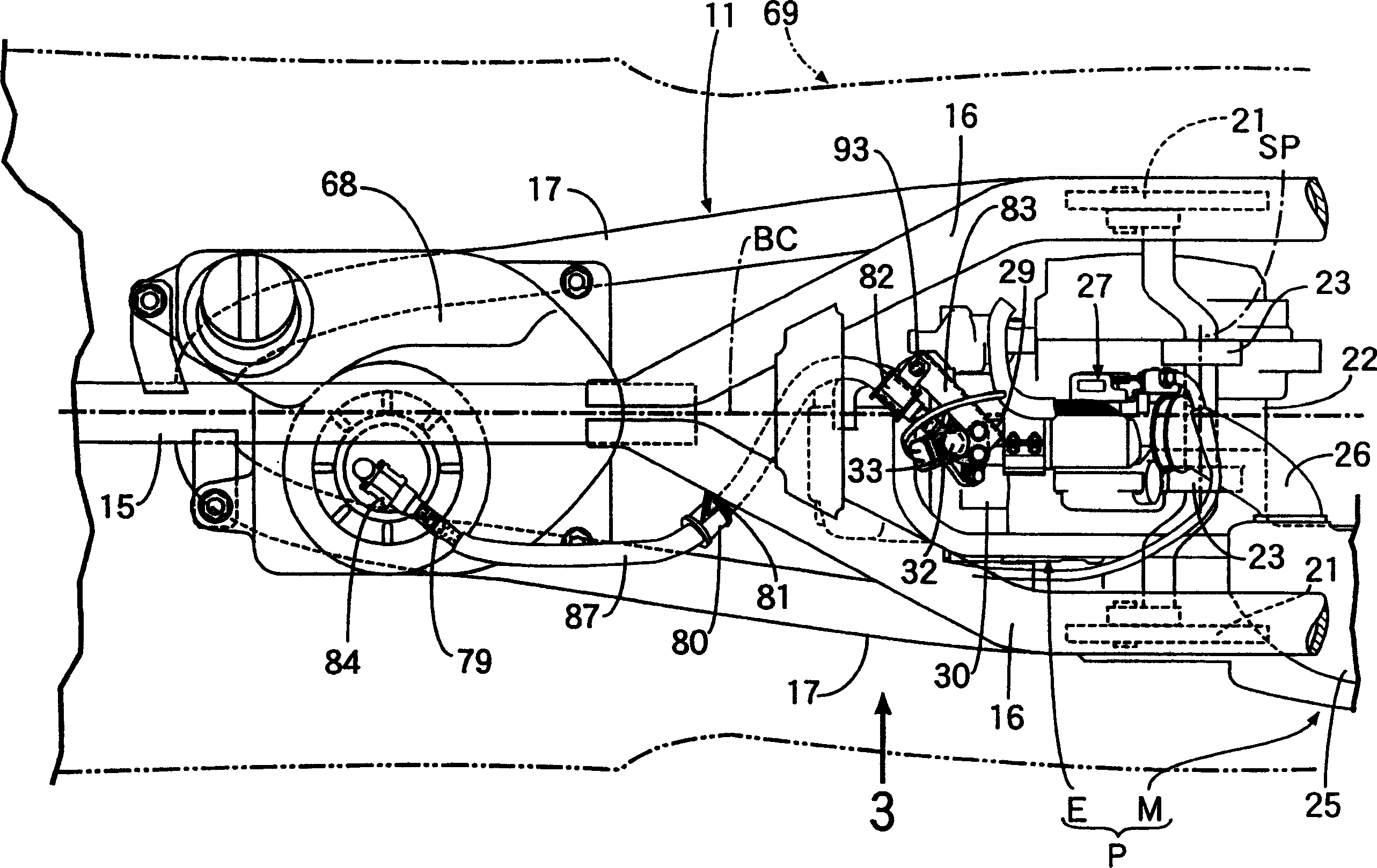

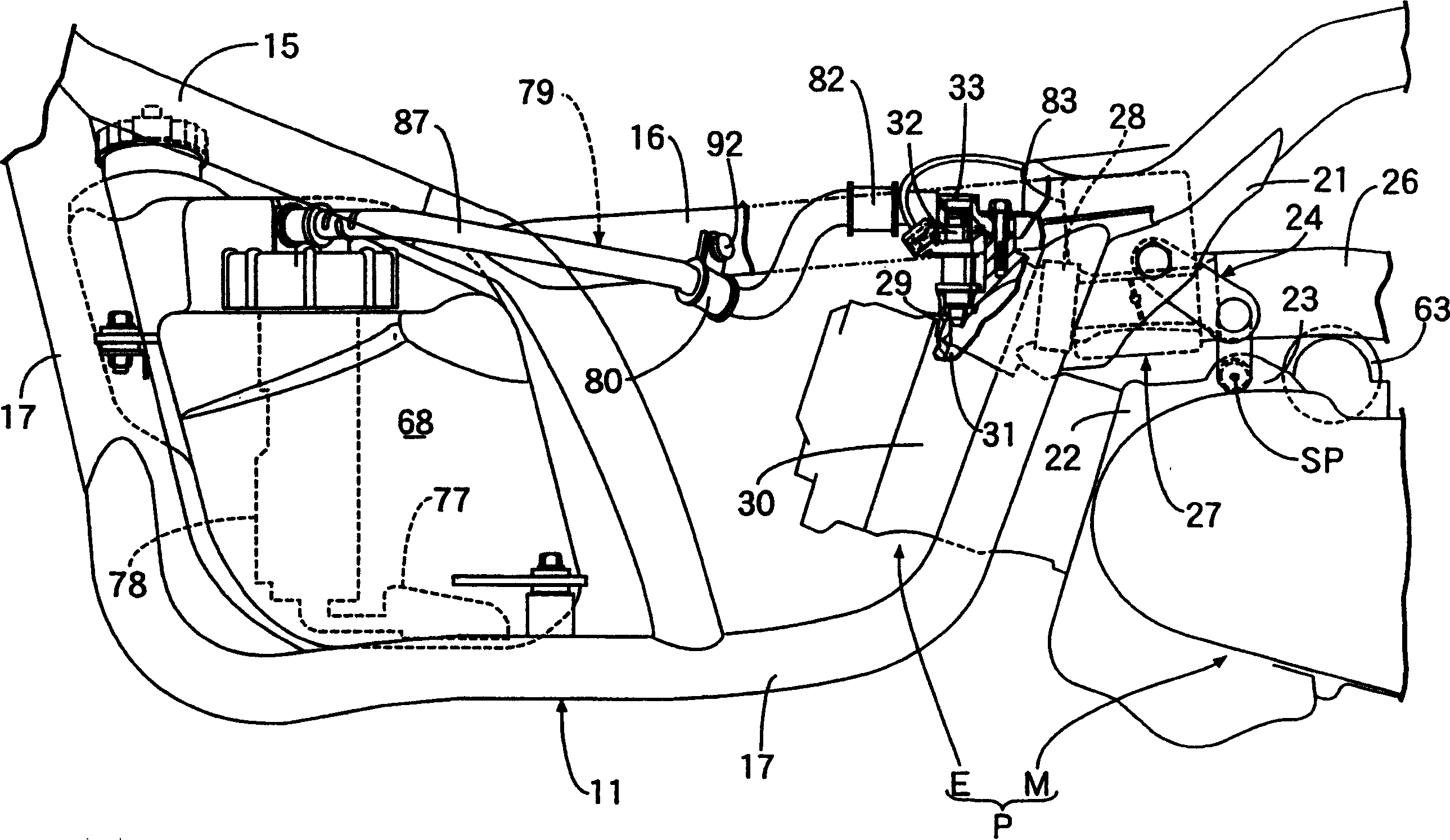

[0020] The implementation of the present invention will be described below in conjunction with an embodiment of the present invention shown in the accompanying drawings.

[0021] figure 1 ~9 represent an embodiment of the present invention, figure 1 is a side view of a small two-wheeled motor vehicle, figure 2 The state of the body cover is omitted figure 1 The view of arrow 2 in the middle, image 3 yes figure 2 The view of the arrow 3 in the middle, Figure 4 yes figure 2 An enlarged view of the main part of the Figure 5 is to move the throttle body device from Figure 4 The side view viewed from the direction of the middle arrow 5, Image 6 is a top view in cross section of the throttle body assembly, Figure 7 is a side view with part of the fuel pipe cut away, Figure 8 It is an enlarged side view showing the longitudinal section of the mounting portion of the intake pipe of the fuel injection valve, and FIG. 9 is Figure 8 The view of the arrow 9 in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com