Semiconductor device and method for producing the same

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of core layer strength reduction, bending, and installation reliability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

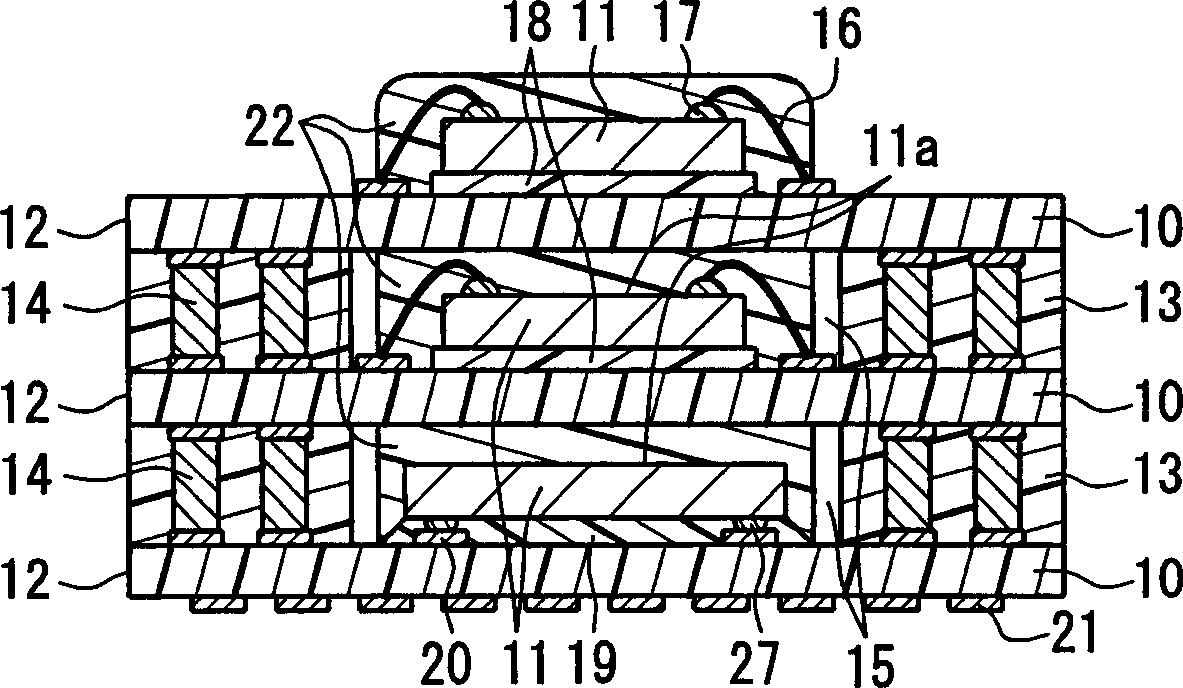

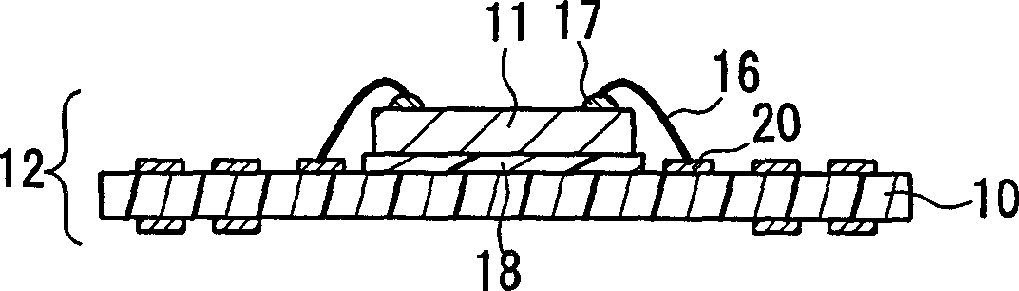

[0061] figure 1 A cross-sectional view of a semiconductor device according to Embodiment 1 of the present invention is shown. Such as figure 1 As shown, the semiconductor device of Embodiment 1 has three circuit boards 12 including a base material 10 and a semiconductor element 11 mounted on the base material 10, and the three circuit boards 12 are connected by a sheet 13 made of a thermosetting resin composition. bonding. These three circuit boards 12 are electrically connected by via conductors 14 penetrating through the sheet 13 , and the semiconductor element 11 arranged between the base materials 10 is housed in the element accommodating portion 15 provided on the sheet 13 . exist figure 1 Among them, 16 is a wire, 17 is an electrode, 18 is a die solder, 19 is an underfill (underfill), 20 is an electrode for component mounting, 21 is an electrode for external connection, and 27 is a gold bump.

[0062] The semiconductor element 11 is not particularly limited, and for ...

Embodiment approach 2

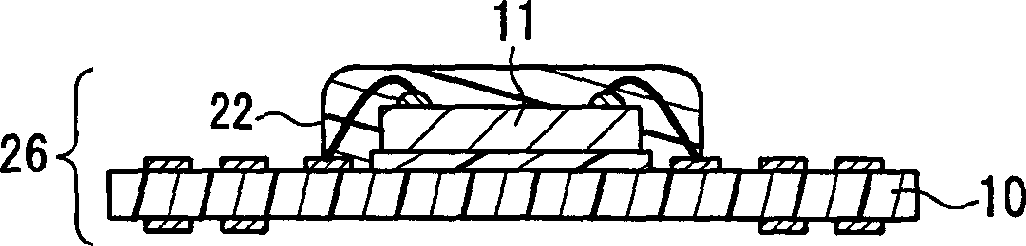

[0089] image 3 A cross-sectional view of a semiconductor device according to Embodiment 2 of the present invention is shown. Such as image 3 As shown, in the semiconductor device of Embodiment 2, all of the semiconductor elements 11 are flip-chip mounted. Moreover, in image 3 On the base material 10 in the middle upper part and the middle part, a through hole 24 communicating with the element receiving part 15 is formed, and on the inner surface of the through hole 24, a connection between wirings to be formed on both main surfaces of the base material 10 is formed. Through conductors 25 for electrical connection between them. Furthermore, a low-elasticity material 22 is filled in the void in the element housing portion 15 . Thus, the semiconductor device of Embodiment 2 has no voids inside it. Others and the above-mentioned semiconductor device of Embodiment 1 (refer to figure 1 )same.

[0090] Since the semiconductor device according to the second embodiment includ...

Embodiment approach 3

[0099] Figure 5 A cross-sectional view of a semiconductor device according to Embodiment 3 of the present invention is shown. Such as Figure 5 As shown, in the semiconductor device according to Embodiment 3, four circuit boards 12 are laminated. Furthermore, through-holes 24 and through-conductors 25 are formed in all base materials 10 . again, in Figure 5 The base material 10 at the bottom and the base material 10 above it are respectively mounted with a semiconductor element 11 accommodated in the element accommodation portion 15, and this group of semiconductor elements 11, 11 is accommodated in the element accommodation portion 15 opposite to each other. . Furthermore, the space in the element housing portion 15 including the portion between the upper surfaces 11a, 11a of the group of semiconductor elements 11, 11 is filled with a low-elasticity material 22 . Other cases and the above-mentioned semiconductor device of Embodiment 2 (refer to image 3 )same. Theref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com