Multilayered wiring board and semiconductor device

A multi-layer wiring substrate and semiconductor technology, which is applied in semiconductor devices, semiconductor/solid-state device components, multi-layer circuit manufacturing, etc., can solve the problems of deformation of rigid parts, rigid flexible substrates cannot be installed with high reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0035] First, a first embodiment of the present invention will be described.

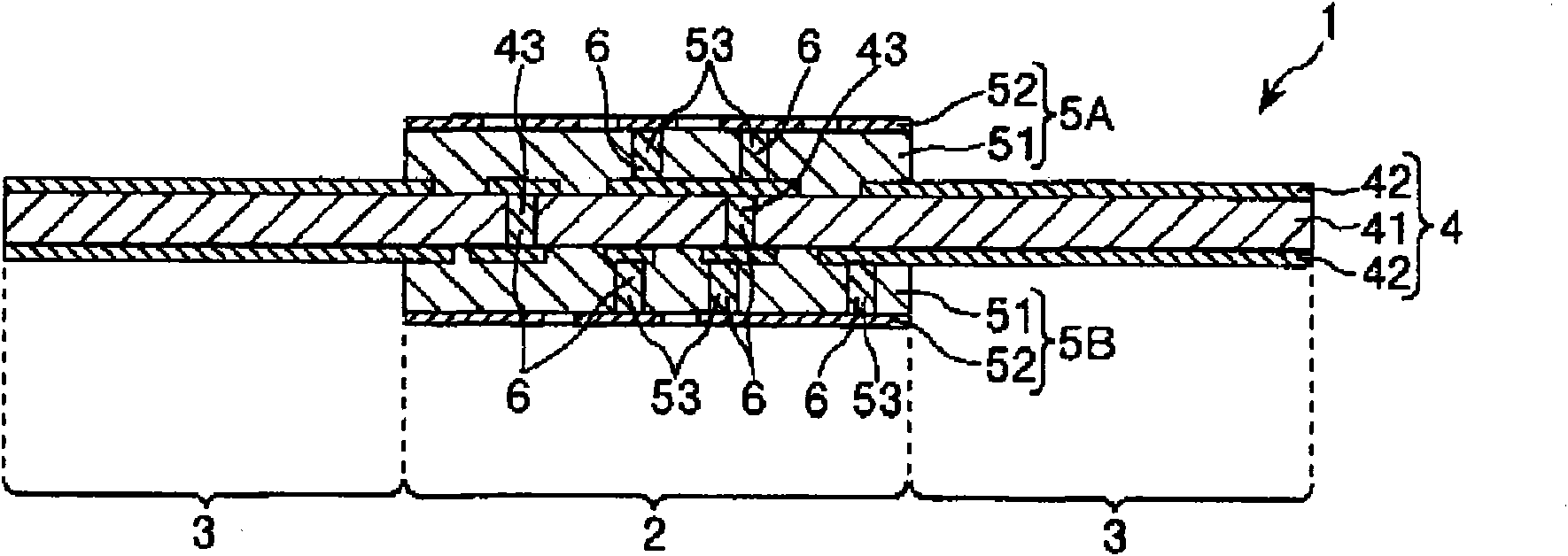

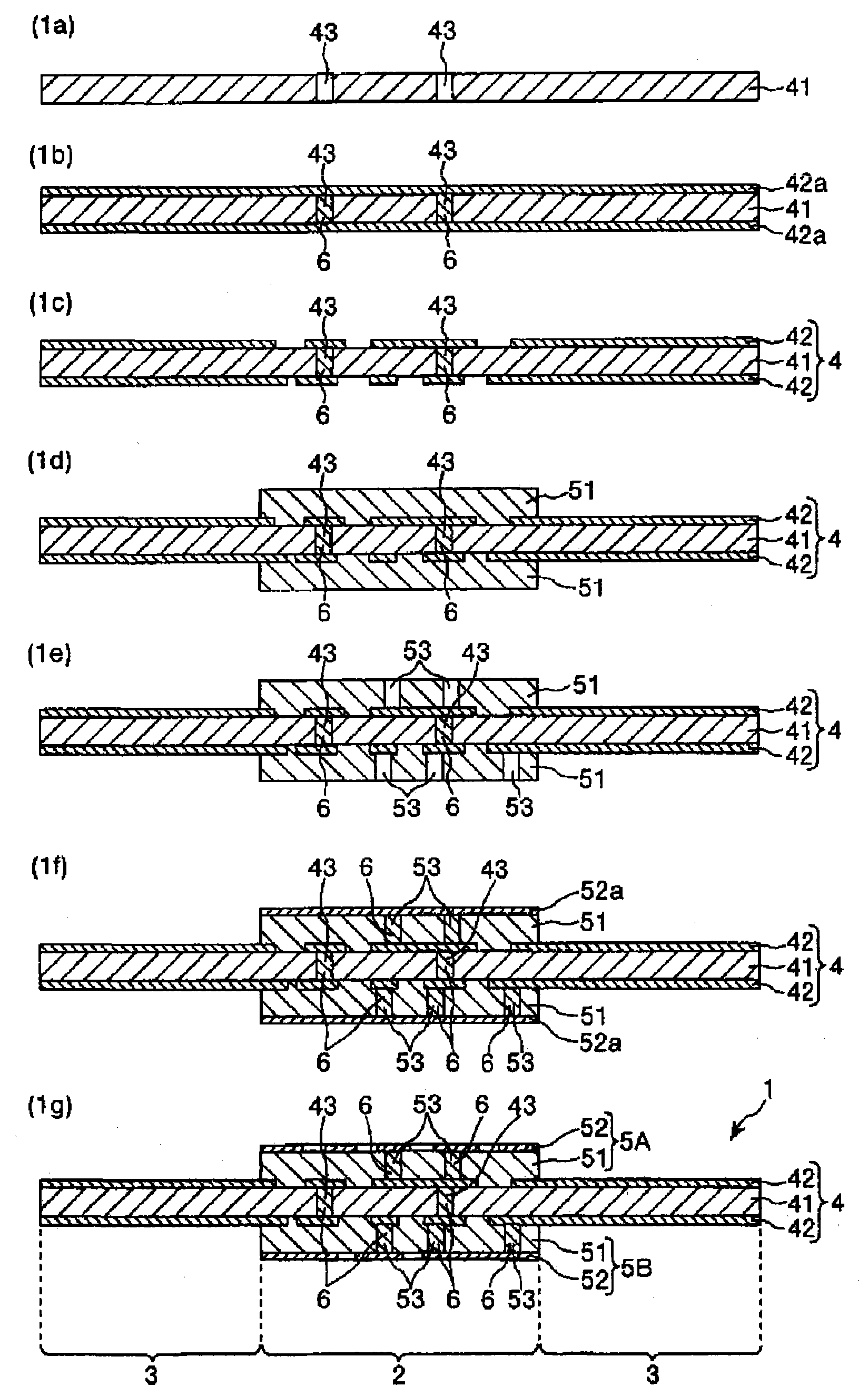

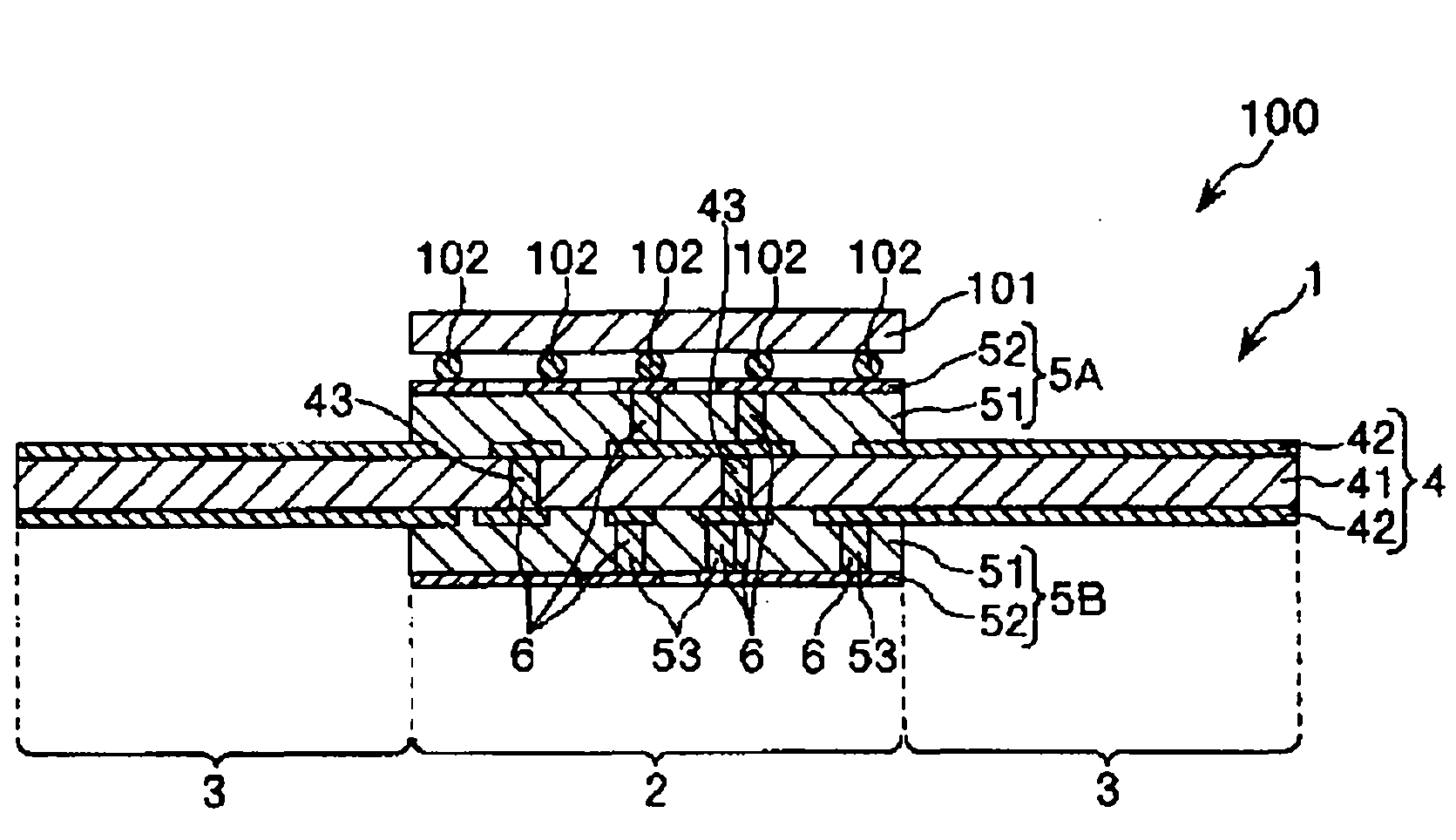

[0036] figure 1 It is a longitudinal sectional view showing the first embodiment of the multilayer wiring board of the present invention, figure 2 yes means figure 1 A vertical cross-sectional view of a preferred method of manufacturing a multilayer wiring substrate is shown, image 3 It is a longitudinal cross-sectional view showing the semiconductor device of this embodiment. In addition, for the convenience of explanation below, the figure 1 , figure 2 The upper side is referred to as "upper" or "upper", and the lower side is referred to as "lower" or "below".

[0037] like figure 1 As shown, the multilayer wiring substrate 1 has: a rigid part 2 having high rigidity; and a flexible part 3 having flexibility connected to both ends of the rigid part 2 .

[0038]

[0039] First, the rigid portion 2 will be described.

[0040] like figure 1 As shown, the rigid part 2 has high rigidity, a...

no. 2 approach

[0170] Next, a second embodiment of the present invention will be described.

[0171] Figure 4 is a longitudinal sectional view showing a second embodiment of the multilayer wiring board of the present invention, Figure 5 , Image 6 , Figure 7 yes means Figure 4 A vertical cross-sectional view of a preferred method of manufacturing the multilayer wiring board shown. In addition, in the following, for convenience of description, the upper side in the figure is called "upper" or "upper", and the lower side is called "lower" or "below".

[0172] Next, a second embodiment of the present invention will be described with reference to the drawings. However, differences from the above-mentioned embodiment will be mainly described, and descriptions of the same matters will be omitted.

[0173] Multilayer wiring board 1A has rigid portion 2 and flexible portion 3 extending from rigid portion 2 .

[0174] The rigid portion 2 has: a first base material 4A having flexibility; a s...

Embodiment 1

[0241] [1-1] Preparation of resin varnish

[0242] In methyl ethyl ketone as an organic solvent, a predetermined amount of each resin material, inorganic filler, and coupling agent shown below was added so that the solid content reached 50% by weight, and stirred for 10 minutes using a high-speed stirrer to obtain A resin varnish in which a prepolymer of a resin material and an inorganic filler are dispersed and / or dissolved in an organic solvent.

[0243] As the prepolymer of cyanate resin, 30 parts by weight of novolac type cyanate resin (primaset PT-60, weight average molecular weight: about 2600, manufactured by Lonza Japan Co., Ltd.) and 10 parts by weight of novolac Cyanate resin (primaset PT-30, weight average molecular weight: about 700, manufactured by Lonza Japan Co., Ltd.). As a prepolymer of the epoxy resin, 8 parts by weight of biphenyl dimethylene type epoxy resin (NC-3000P, epoxy equivalent: 275 g / eq, Nippon Kayaku Co., Ltd.) was used. As the prepolymer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com