Finished product conveying equipment for cosmetic production

A technology for conveying equipment and cosmetics, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of mixing cosmetic bottles, affecting the quality of cosmetic bottle packaging products, and low work efficiency of automated assembly lines. Sexual value, increase work efficiency and practical value, reduce the effect of material blocking or leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

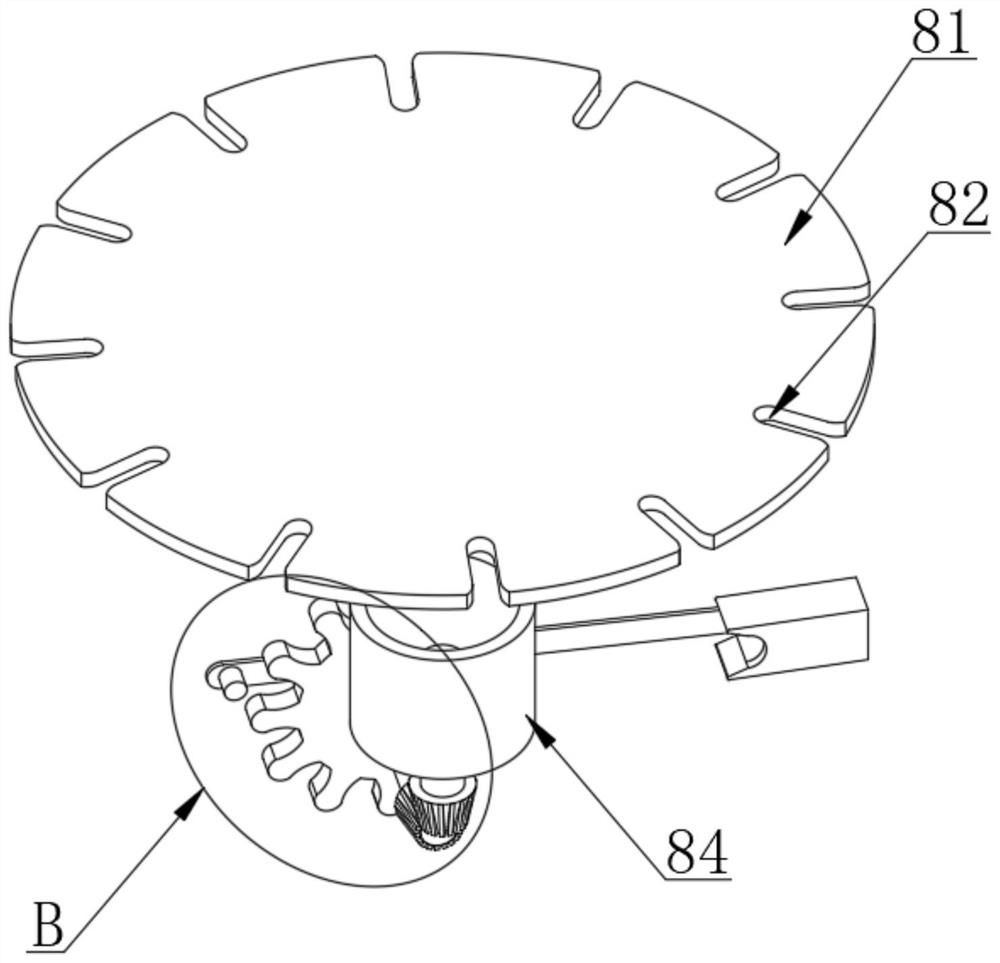

[0040] The embodiment is specifically: using the low-concentration lubricating oil on the surface of the first bevel tooth 79 and the second bevel tooth 83, the friction force between the two is relatively small when they are meshed with each other, and the wear rate of the two is low. .

[0041] Working principle of the present invention:

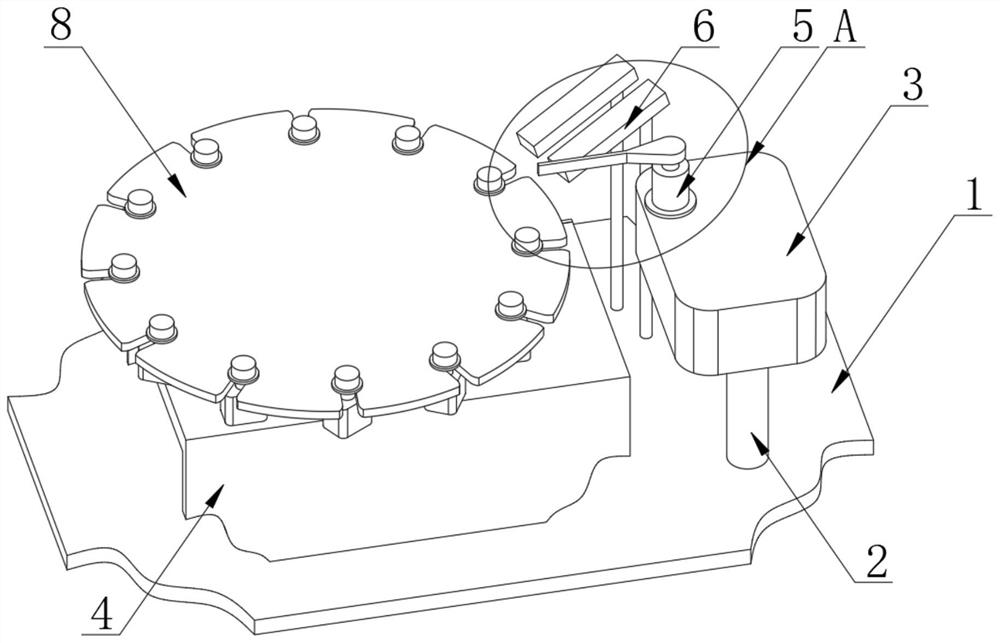

[0042] Step 1: First, the operator normally assembles the various components of the device, and then starts the device normally.

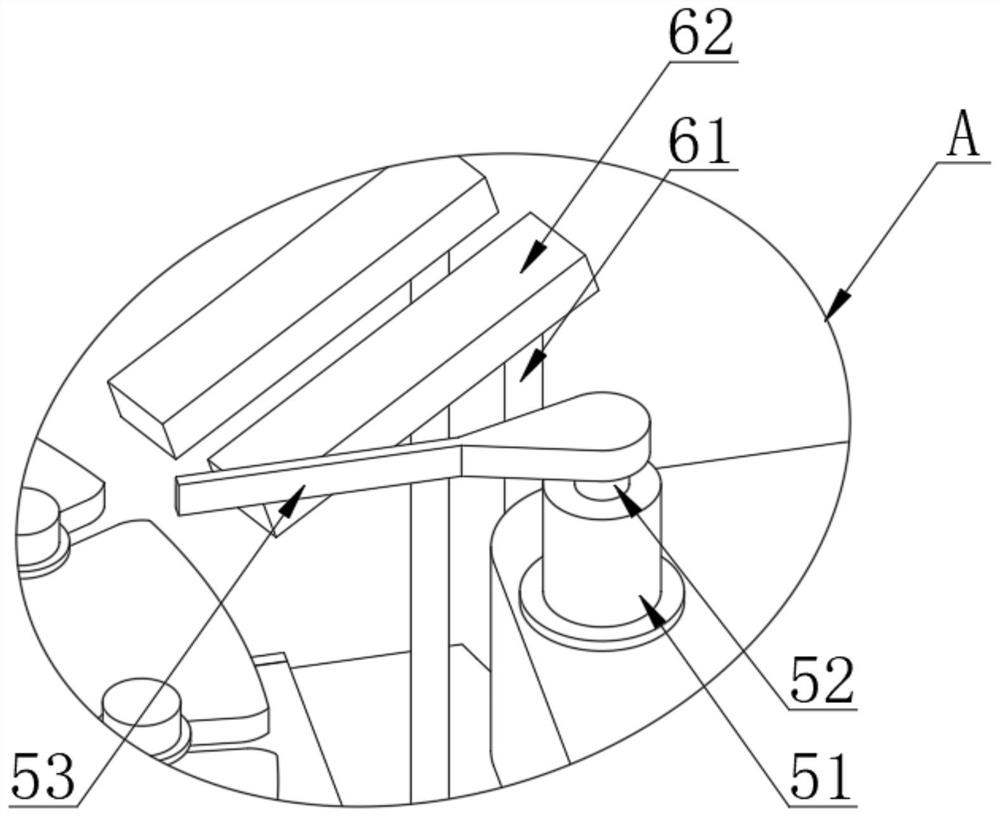

[0043] The second step: firstly, the operator introduces the material to the surface of the material guide slant plate 62 through the material conveying assembly 6, and then the electric telescopic rod 52 drives the strip baffle 53 to rise, and under the action of the control box 3, from the right Rotate to the left, and at the same time, the strip baffle 53 pushes the cosmetic bottle scraped by the guide sloping plate 63 to the inside of the limit groove 82 on the surface of the turntable 81 obliquely below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com