Agricultural Press

a technology for pressing presses and agricultural products, applied in the field of pressing presses, can solve problems such as producing even greater jams, and achieve the effects of preventing uncontrolled accumulation of materials, low friction resistance, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

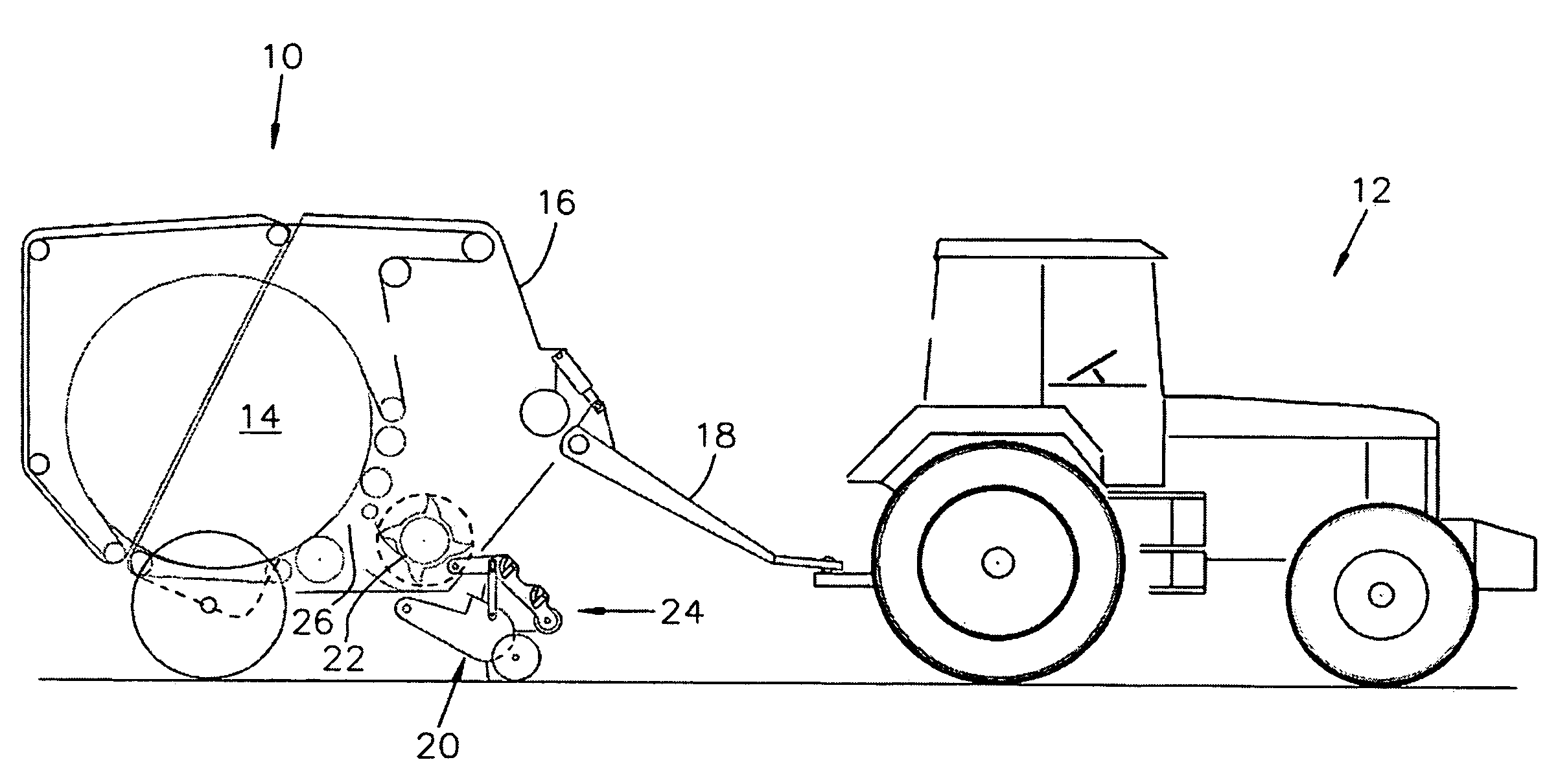

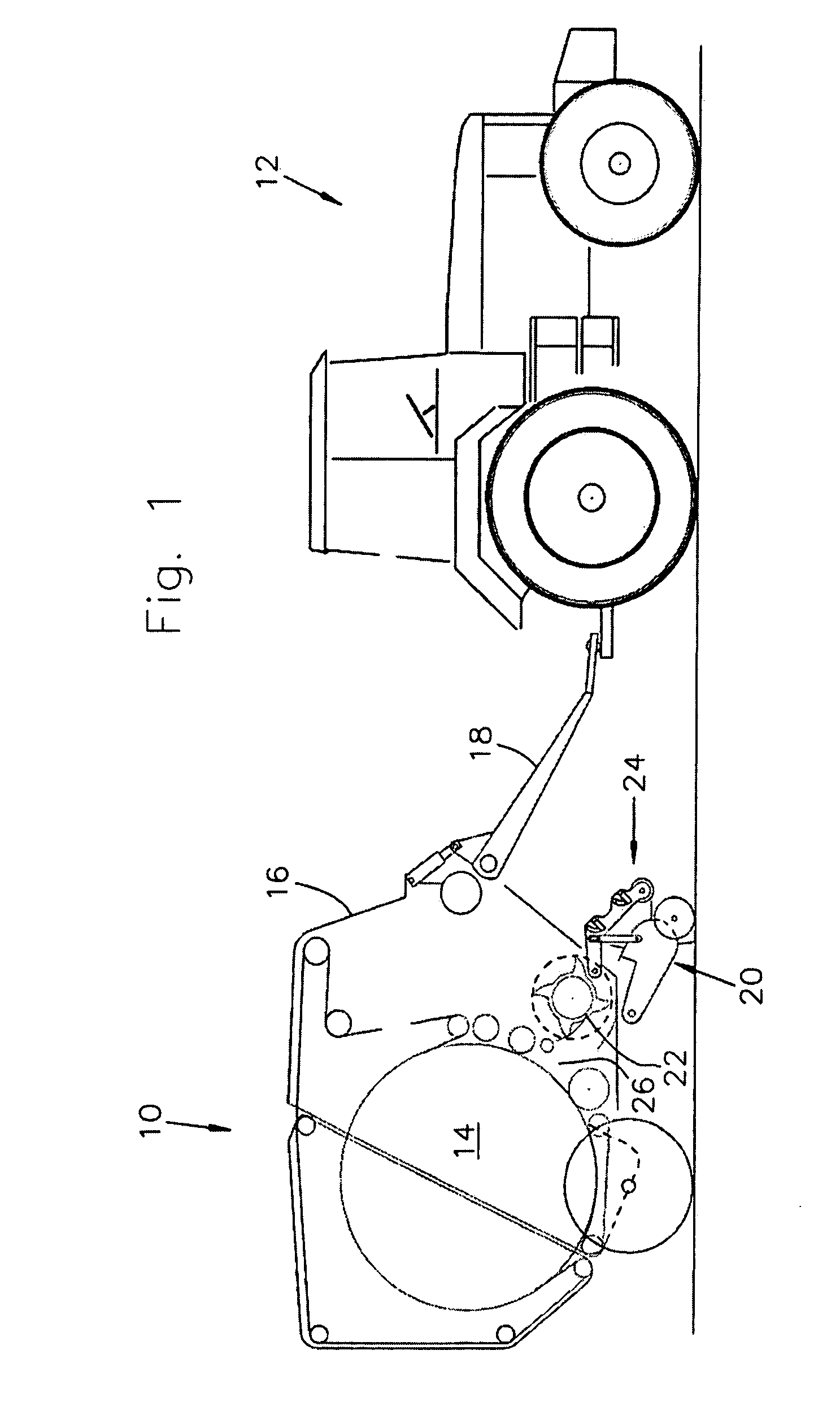

[0024]FIG. 1 shows an agricultural press 10 behind a tractor 12, as they are generally known.

[0025]The agricultural press 10 is configured as a round baler with a variable pressing chamber 14; it could also, however, be a different press, a forage harvester, a loader wagon or the like, in which comparable problems arise.

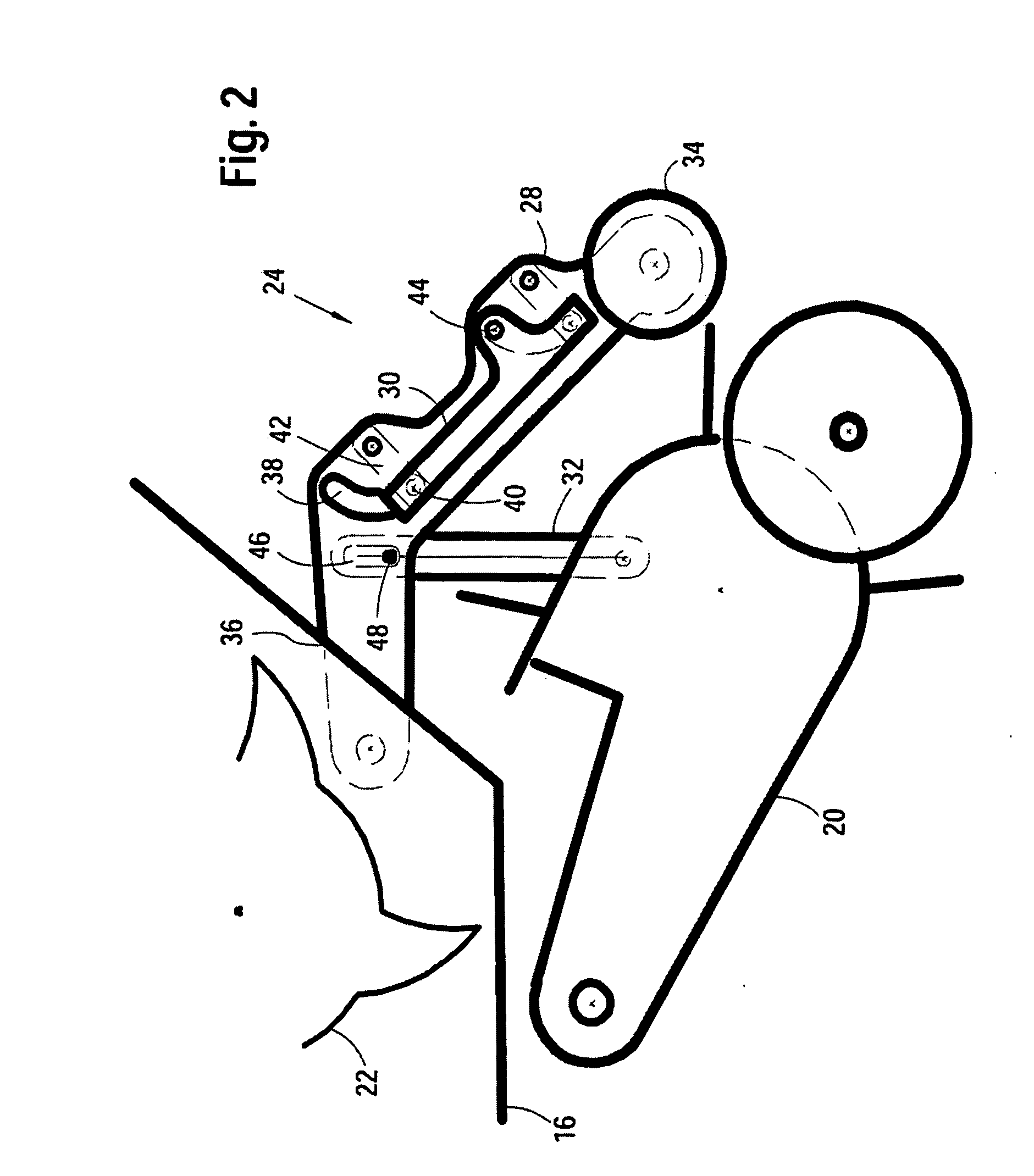

[0026]The agricultural press 10 has a frame 16, a drawbar 18, a material receiver 20, a feed rotor 22 and a material hold-down device 24. As is known, the agricultural press 10, by means of the material receiver 20, gathers material from the ground, which is deposited there in swaths and can consist, for example, of hay, straw or silage. There are also industrial applications, in which waste, materials, tobacco, etc. are pressed. During this material reception, problems can arise if the thickness of the swath is uneven.

[0027]The pressing chamber 14 is provided in the front lower region with an inlet 26, through which the gathered material is fed in by the material re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com