Preparation of 06 grade gypsum based autoclave-free aerated concrete building blocks

An air-entrained concrete and autoclaved-free technology, which is applied to clay preparation devices, chemical instruments and methods, and manufacturing tools, can solve the problems of large one-time investment, large drying shrinkage value, and high production cost, and achieve low investment and low porosity. Small and uniform, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

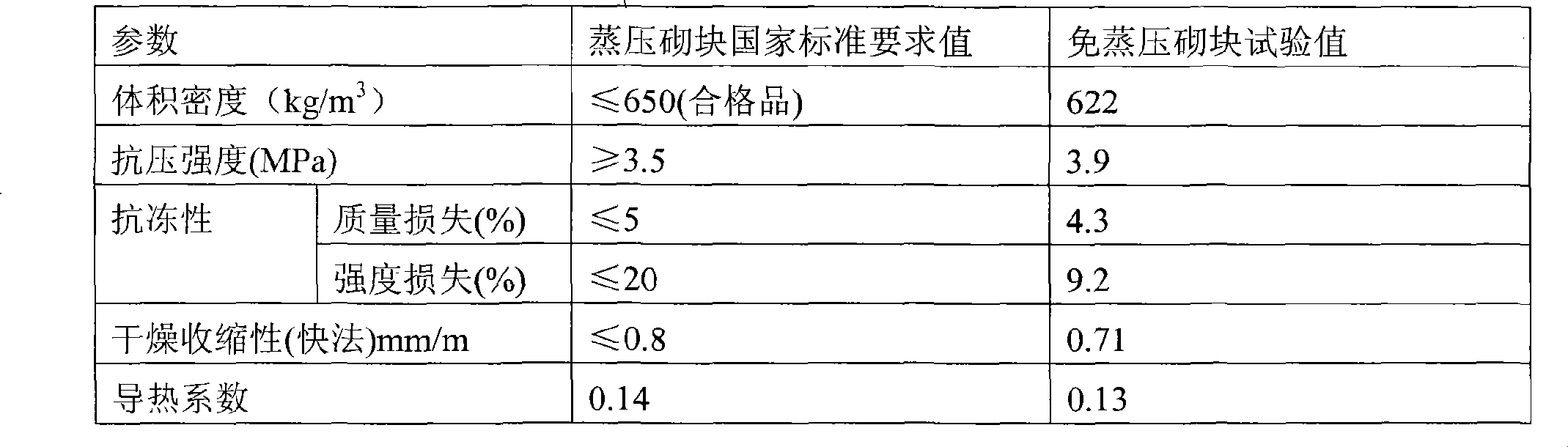

Examples

Embodiment 1

[0028] A preparation method of grade 06 gypsum-based autoclaved aerated concrete block, which comprises the following steps:

[0029] 1) Preparation of raw materials: Dehydrate desulfurized gypsum (chemical waste gypsum). The dehydration system is: dehydration temperature 160°C, constant temperature 30min; dehydration and aging for 5 days to obtain desulfurized building gypsum; the CaSO in the desulfurized gypsum 4 2H 2 The O content is more than 90% (mass), and the fineness is 0.08mm, and the remaining 5-8% is sieved;

[0030] 2) Selection of raw materials: The composite cementitious material is composed of desulfurized building gypsum, fly ash, lime and cement, according to the mass percentage of each raw material: desulfurized building gypsum 58%, fly ash 22%, lime 10%, cement 10%, select desulfurized building gypsum, fly ash, lime and cement;

[0031] Press: the add-on of aluminum powder (gas generating agent) is 0.12% of composite gelling material quality, the add-on of...

Embodiment 2

[0041] A preparation method of grade 06 gypsum-based autoclaved aerated concrete block, which comprises the following steps:

[0042] 1) Preparation of raw materials: dehydrate desulfurized gypsum (chemical waste gypsum), the dehydration system is: dehydration temperature 140°C, constant temperature 25min; after dehydration, age for 4 days to obtain desulfurized building gypsum; the CaSO in the desulfurized gypsum 4 2H 2 O content is 91% (mass), fineness 0.08mm sieve remaining 5%;

[0043]2) Selection of raw materials: The composite cementitious material is composed of desulfurized building gypsum, fly ash, quicklime and cement. According to the mass percentage of each raw material: desulfurized building gypsum 55%, fly ash 26%, lime 10%, cement 9%, select desulfurized building gypsum, fly ash, lime and cement;

[0044] Press: the add-on of aluminum powder (gas generating agent) is 0.1% of composite gelling material quality, the add-on of degreaser saponin powder is 0.07% of...

Embodiment 3

[0052] A preparation method of grade 06 gypsum-based autoclaved aerated concrete block, which comprises the following steps:

[0053] 1) Preparation of raw materials: dehydrate desulfurized gypsum (chemical waste gypsum), the dehydration system is: dehydration temperature 180°C, constant temperature 35min; after dehydration, age for 6 days to obtain desulfurized building gypsum; in the desulfurized gypsum, CaSO 4 2H 2 The O content is 98% (mass), and the fineness 0.08mm sieves 8%;

[0054] 2) Selection of raw materials: The composite cementitious material is composed of desulfurized building gypsum, fly ash, quicklime and cement. According to the mass percentage of each raw material: desulfurized building gypsum 60%, fly ash 22%, lime 10%, cement 8%, select desulfurized building gypsum, fly ash, lime and cement;

[0055] Press: the add-on of aluminum powder (gas generating agent) is 0.12% of composite gelling material quality, the add-on of degreaser saponin powder is 0.09% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com