Air exhaust, defoaming and stirring device for finishing agent

A stirring device and finishing agent technology, which is applied in the field of textile production, can solve the problems of high production cost of finishing agents, achieve the effects of shortening the stirring time, improving production efficiency, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

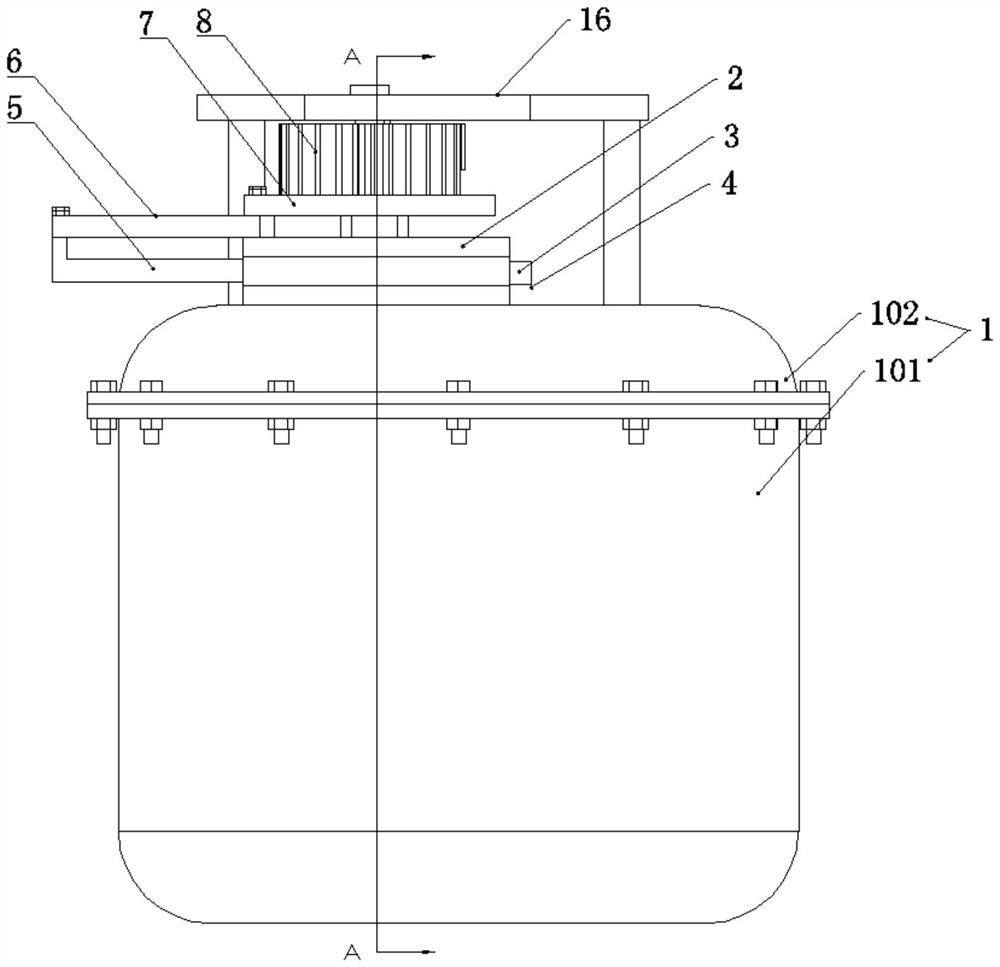

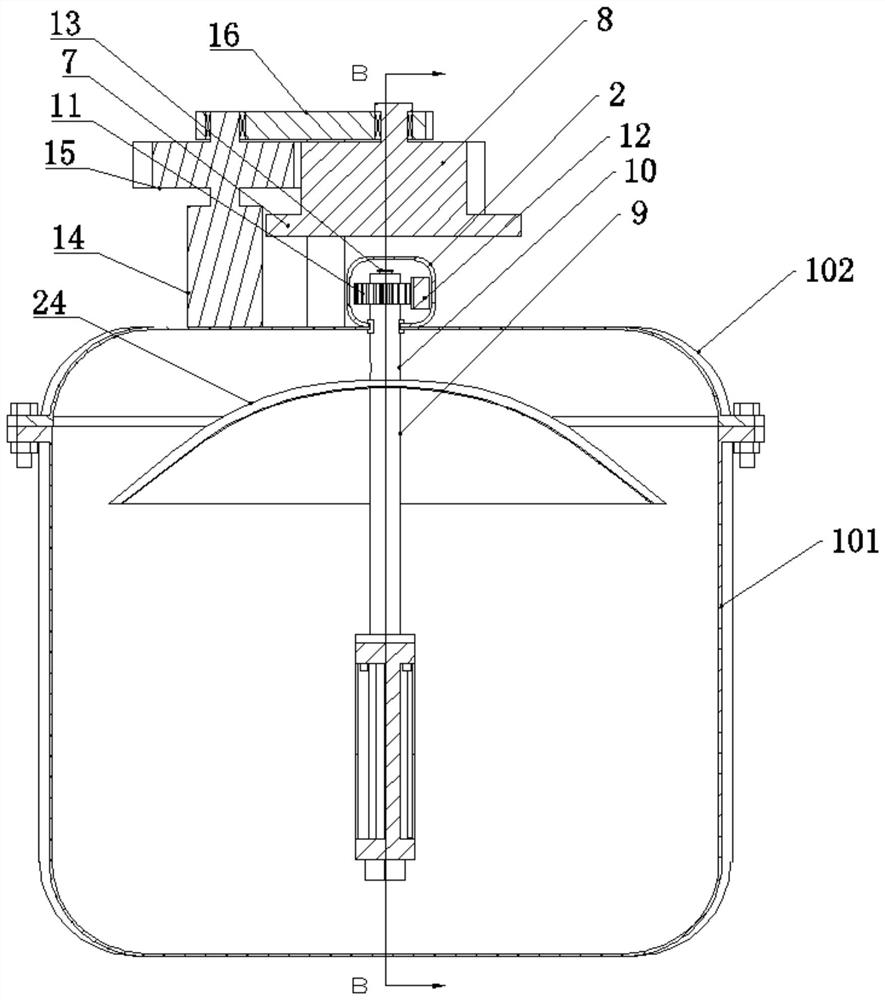

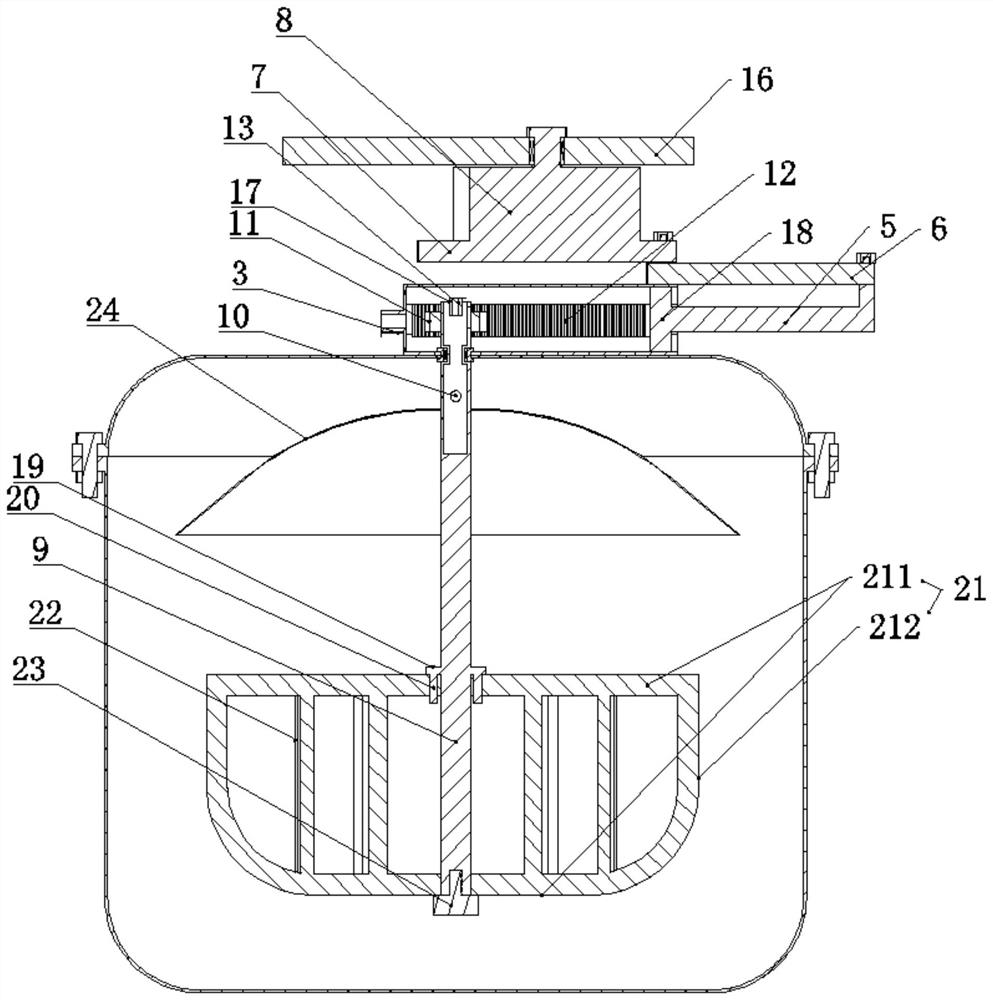

[0035] A finishing agent suction defoaming stirring device, refer to Figure 1-Figure 4 As shown, it includes a tank body 1 and a stirring mechanism arranged in the tank body 1. The tank body 1 includes a stirring tank 101 with an opening upward and a tank cover 102 that is detachably sealed and arranged on the stirring tank 101. The tank cover 102 and the stirring tank 101 Between them are locked by bolts and nuts. The stirring mechanism includes a vertical rotating shaft 9 and a stirring blade 21 arranged on the rotating shaft 9. The stirring blade 21 includes a horizontal stirring rod 211 arranged in parallel up and down and an upper and lower horizontal stirring rod 211. The vertical stirring rod 212 is connected between the ends of the horizontal stirring rods 211, and the stirring blade 22 is arranged between the upper and lower horizontal stirring rods 211. The rotating surface of the stirring blade 22 is set as a blade portion 221, and the stirring blade 21 is detachabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com