Long-acting antibacterial and mildew-proof PP/PS plastic and preparation method thereof

A technology of antibacterial and antifungal, antibacterial and antifungal agent, which is applied in the field of long-acting antibacterial and antifungal PP/PS plastics and its preparation, can solve the problems of low mixing efficiency, high cost, and high requirements for ground flatness, and improve work efficiency , improve the uniformity, reduce the effect of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

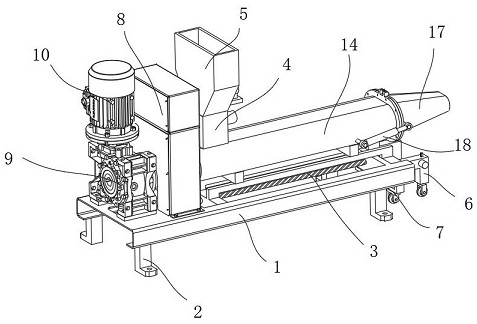

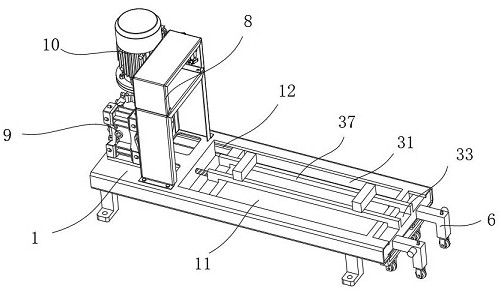

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

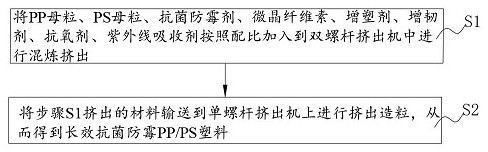

[0037] In the specific implementation process, such as Figure 1-5 As shown, a long-acting antibacterial and mildew-proof PP / PS plastic preparation method is completed by using a twin-screw extruder. The preparation method includes:

[0038] S1. Add PP masterbatch, PS masterbatch, antibacterial and antifungal agent, microcrystalline cellulose, plasticizer, toughener, antioxidant, and ultraviolet absorber to the twin-screw extruder according to the ratio for mixing squeeze out

[0039] S2. Transport the material extruded in step S1 to a single-screw extruder for extrusion and granulation, so as to obtain long-acting antibacterial and antifungal PP / PS plastics; "S1" and "S2" specifically indicate "step one" , "Step 2";

[0040] The four temperature sections in the mixing and extrusion process are: feeding section 110-120°C, conveying section 125-135°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com