Preparation method of hyaluronic acid filling agent

A technology of hyaluronic acid and hyaluronidase, which is applied in the field of material science, can solve the problems of difficulty in ensuring the mixing effect, rejection reaction, and uneven particles, so as to shorten the time for uniform mixing, prolong the time of action, and avoid Gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

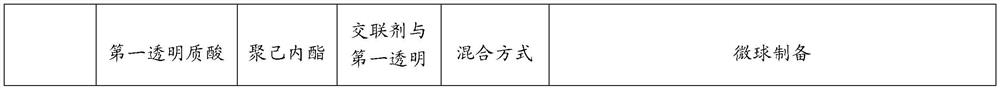

[0036] The present invention provides a kind of preparation method of hyaluronic acid filler, and described preparation method comprises the following steps:

[0037] uniformly mixing the dried first hyaluronic acid or its salt with the dried degradable polymer microspheres to obtain starting materials;

[0038] Cross-linking the starting material with a cross-linking agent, purifying, and granulating to obtain hyaluronic acid gel containing microspheres;

[0039] The hyaluronic acid gel containing the microspheres is purified, filled, and sterilized to obtain a hyaluronic acid filler.

[0040] In a specific embodiment, the mass ratio of the first hyaluronic acid or its salt to the degradable polymer microspheres is 1:0.01˜1:1. For example, it can be 1:0.01, 1:0.1, 1:0.2, 1:0.3, 1:0.4, 1:0.5, 1:0.6, 1:0.7, 1:0.8, 1:0.9, 1:1.

[0041] In a specific embodiment, the mass ratio of the cross-linking agent to the first hyaluronic acid or its salt is 0.5-4:100, for example, it can ...

Embodiment 1

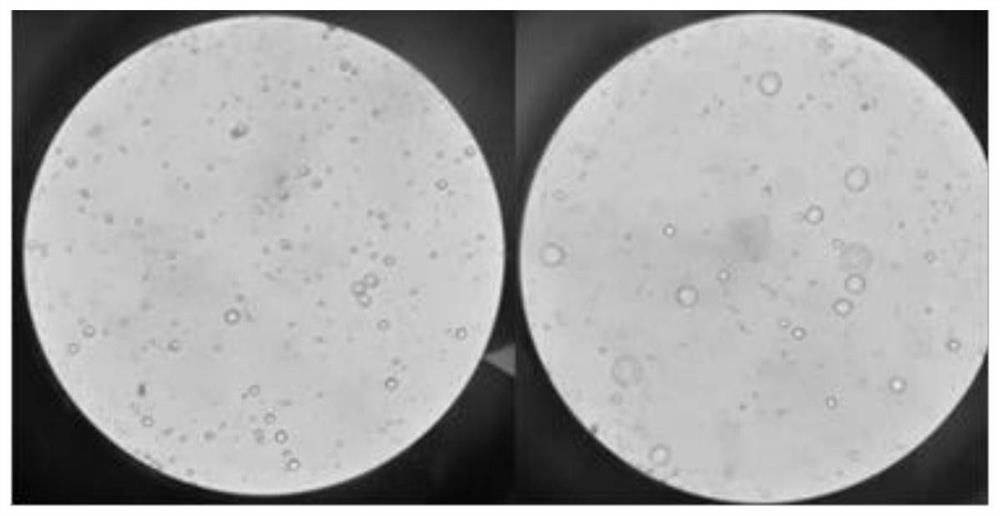

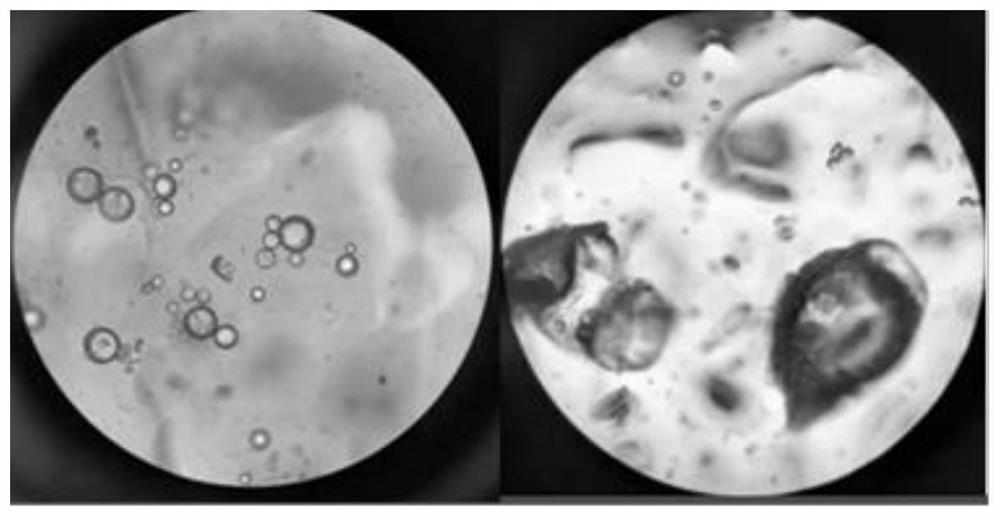

[0073] (1) Preparation of polycaprolactone microspheres

[0074] Weigh 1 g (60 kDa) of polycaprolactone and dissolve it in 10 ml of dichloromethane to obtain the first solution. Weigh 0.1 g of hyaluronic acid (molecular weight of hyaluronic acid is 1000 kDa) as the second hyaluronic acid and dissolve it in 100 g of water (the content of hyaluronic acid is 1 mg / g), and add 10000 IU of hyaluronidase to obtain the second solution. After the second solution is prepared, the first solution is sprayed into the second solution through an ultrasonic atomizer immediately, and the diameter of the droplet particles formed by ultrasonic atomization of the first solution is adjusted to 100 microns. During this process, the second solution was stirred and heated at the same time, wherein the reaction temperature was set at 42° C. until the organic solvent was completely volatilized, and crude polycaprolactone microspheres were obtained. The obtained crude polycaprolactone microspheres were...

Embodiment 2

[0078] The difference between Examples 2-4 and Example 1 is that the quality of polycaprolactone microspheres is different, and other reaction conditions are the same as Example 1. Specifically, in embodiment 2, the quality of polycaprolactone microsphere is 0.05g; In embodiment 3, the quality of polycaprolactone microsphere is 0.01g; In embodiment 4, the quality of polycaprolactone microsphere The mass of the ball is 1g. Specifically, the main reaction parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com